Method for processing percolate membrane treatment concentrated solution of refuse landfill

A landfill and leachate technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the fouling of disc tube filter membranes, affect the service life and Water treatment effect and other issues, to achieve the effect of reasonable process setting, strong practicability, and reduced equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

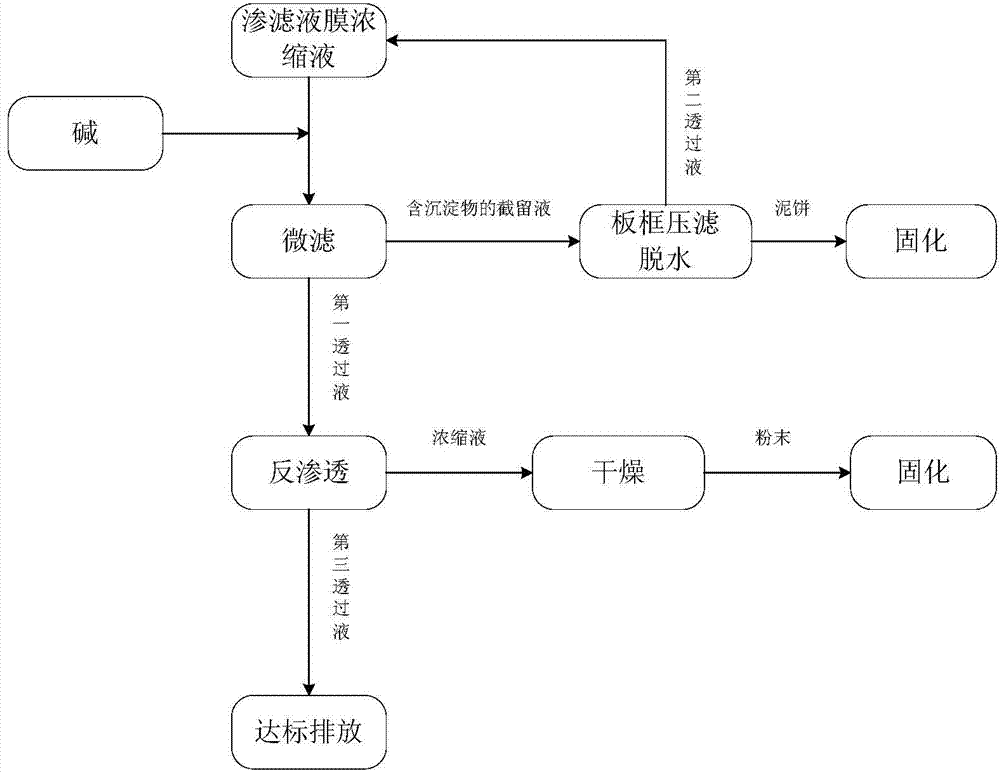

Image

Examples

Embodiment 1

[0034] The combined process disclosed by the invention is used to treat the leachate membrane treatment concentrate of a landfill site.

[0035] The landfill first uses denitrification and nitrification processes for treatment, and then uses an external membrane bioreactor for mud-water separation. The effluent is treated with nanofiltration membranes, and the effluent of nanofiltration membranes is discharged after being treated with reverse osmosis membranes. After membrane treatment, the concentration of CODcr in the concentrated solution is 1500mg / L, the total hardness content is 1800mg / L, the conductivity is 5600μs / cm, and the pH is 7.2.

[0036] (1) Take 5 tons of membrane treatment concentrate, add industrial grade caustic soda to the membrane treatment concentrate to adjust its pH to 11.5, at this time, the heavy metal ions, calcium and magnesium ions in the concentrate react with caustic soda to generate a large amount of precipitation;

[0037] (2) Filter the above-...

Embodiment 2

[0042] In this example, the combined process disclosed in the present invention is used to treat the leachate membrane treatment concentrate of a landfill, and the landfill adopts the leachate treatment process described in Example 1. After membrane treatment, the concentration of CODcr in the concentrate is 3200mg / L, the total hardness content is 3100mg / L, the conductivity is 8200μs / cm, and the pH is 7.3.

[0043] (1) Take 5 tons of membrane treatment concentrate, add industrial grade caustic soda to the membrane treatment concentrate to adjust its pH to 11.5, at this time, the heavy metal ions, calcium and magnesium ions in the concentrate react with caustic soda to generate a large amount of precipitation;

[0044] (2) Filter the above-mentioned mixed solution containing sediment through a tubular microfiltration membrane. The pore size of the tubular membrane is 0.1 μm, and the operating pressure is 0.4Mpa. After filtration, 4.8 tons of the first permeate and 200L of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com