Method for laser bonding

A bonding method and laser technology, which is applied in the field of laser bonding technology, can solve problems such as pressure deviation, and achieve the effects of improving adhesion, reducing poor welding, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

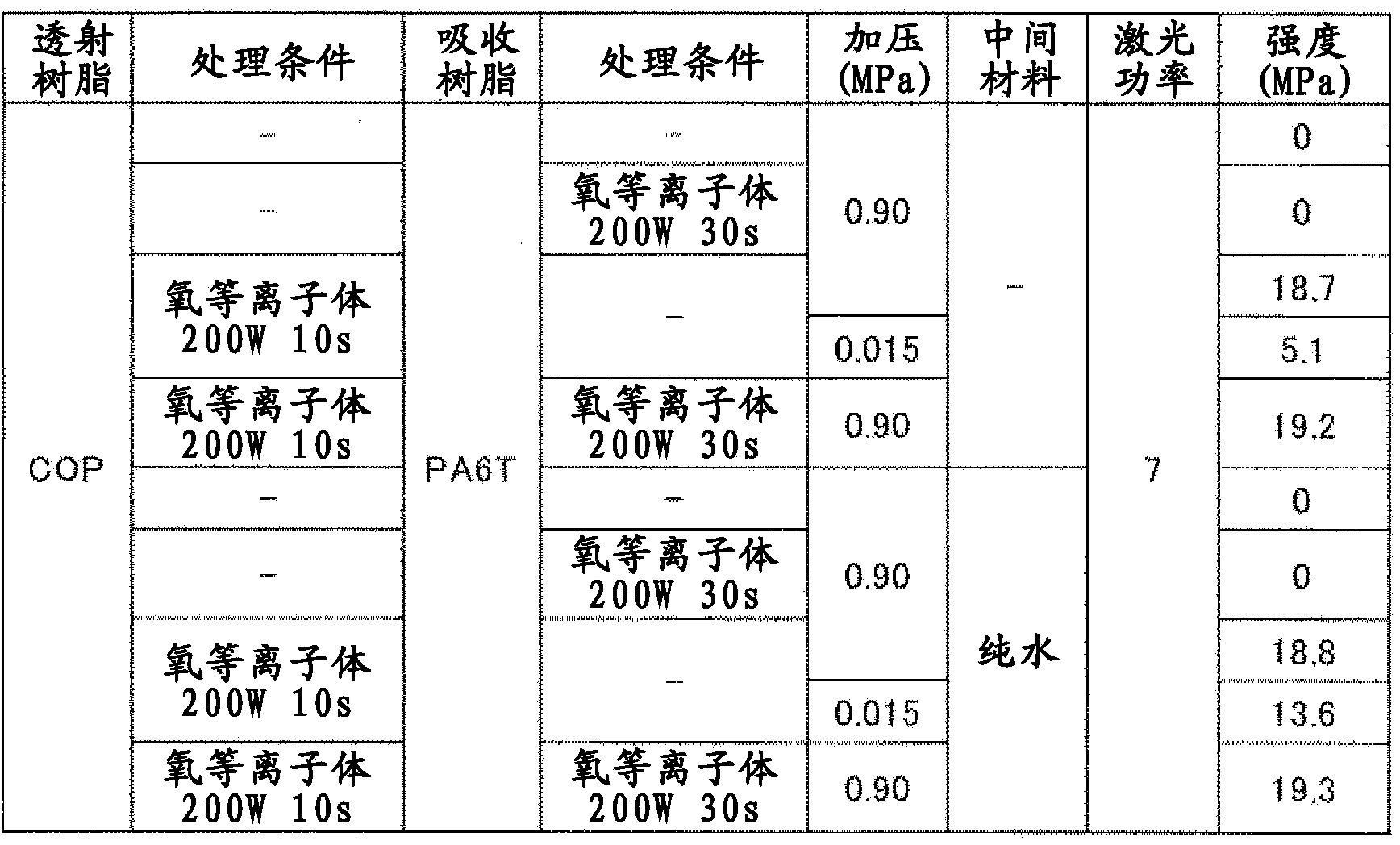

Embodiment 1

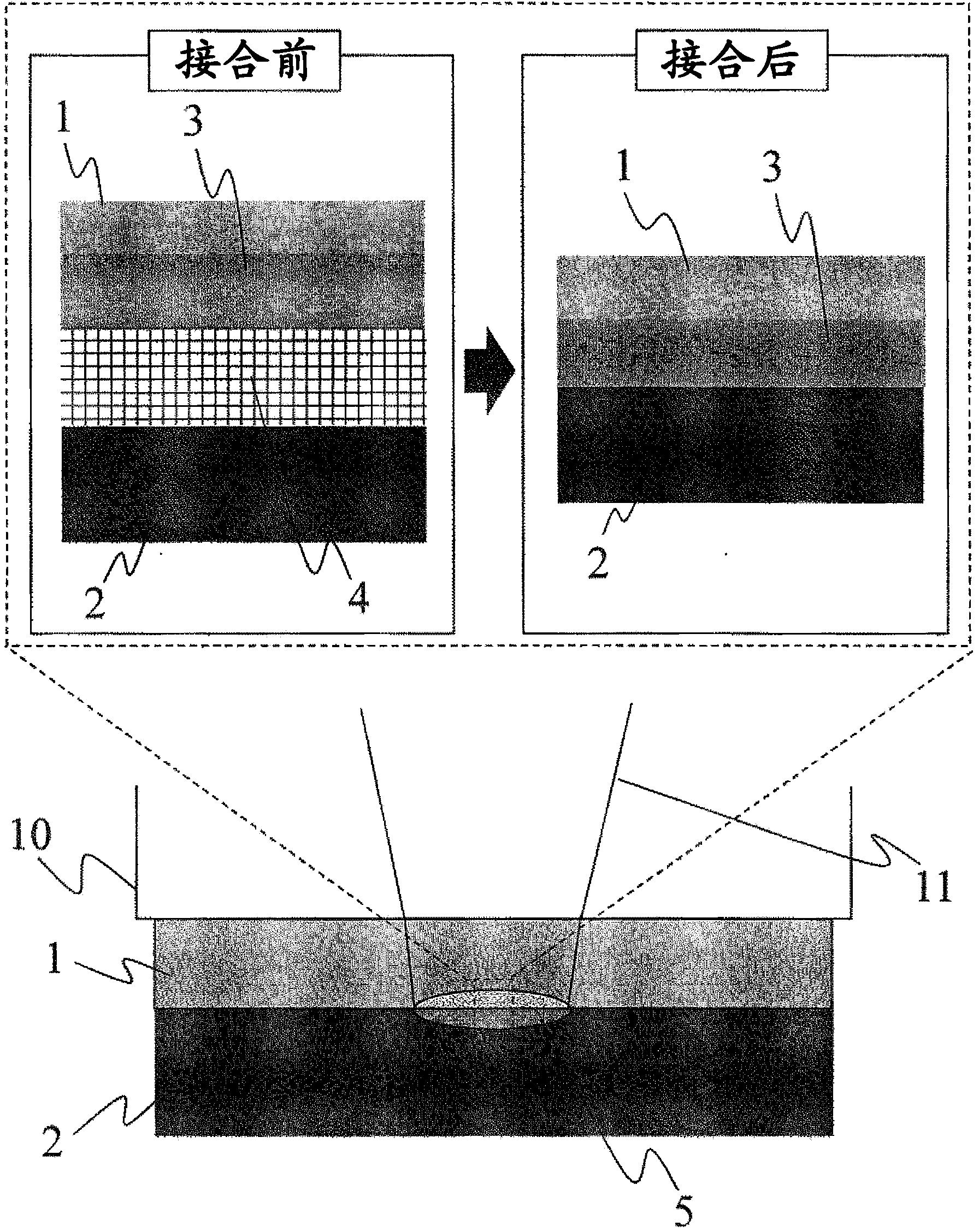

[0034] figure 1 It is a cross-sectional view showing an example of the laser bonding method of resins according to the present invention. In this embodiment, a light-transmitting first thermoplastic resin 1 and a second thermoplastic resin 2 having a light-absorbing property higher than that of the first thermoplastic resin 1 are included. Surface modification treatment is performed to form an oxide layer 3 containing more oxygen than the first thermoplastic resin of the main body at the joint interface, and laser welding is performed under pressure with the liquid intermediate material 4 interposed therebetween.

[0035] For the intermediate material 4 , it is preferable to use a liquid (including a colloidal solution (sol)) material that can sufficiently fill the gap between the thermoplastic resins 1 and 2 . Therefore, it is particularly preferable to use a member with a viscosity of 1000 mPa·s or less, and a solvent with low flammability such as pure water and ethanol, a ...

Embodiment 2

[0046] Figure 6 It is a cross-sectional view showing an example of the laser bonding method of resin and metal of the present invention. Surface modification treatment is performed on the joint interface side of the first thermoplastic resin 1 before joining, and the metal 8 side is pressurized with the liquid intermediate material 4 interposed between the first thermoplastic resin 1 and the metal 8 . Unlike Example 1, laser joining is performed by making laser beam 11 incident from the metal 8 side. By setting it as such a structure, the problem of the transmittance of a thermoplastic resin material which is one of the problems of laser welding is solved. However, in this case, the thickness of the metal 8 is preferably as thin as 4 mm or less. Furthermore, if the surface of the metal 8 to which the laser beam 11 is irradiated is blackened in advance, the absorption rate of the laser beam increases, and the necessary laser power can be reduced, which is a desirable aspect....

Embodiment 3

[0052] Figure 8 It is a cross-sectional view showing another example of the laser bonding method of resins or resins and metals according to the present invention. exist Figure 8 In this case, the pressurizing material 10 is used to pressurize the first thermoplastic resin 1 in a direction (downward in the drawing). If the laser beam 11 is irradiated when the transmittance of the first thermoplastic resin 1 to the laser beam 11 is relatively low at about 20%, there may be cases where the necessary power increases depending on the combination, and the thermoplastic resin 1 on the laser irradiation side Carbonization occurs on the outermost surface, causing problems such as inability to perform laser bonding or adhesion to pressurized materials. Also, even when pressurization is performed using glass, which is a pressurizing material 10 having high thermal conductivity, the glass cannot be brought into contact with the surface of the thermoplastic resin 1 at the interface le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com