Front steam assembly of automobile air conditioner system

A technology of front steam assembly and air conditioner, which is applied in the field of auto parts, can solve the problems of damage, waste and trouble of connecting air duct snaps, and achieve the effect of ingenious design, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

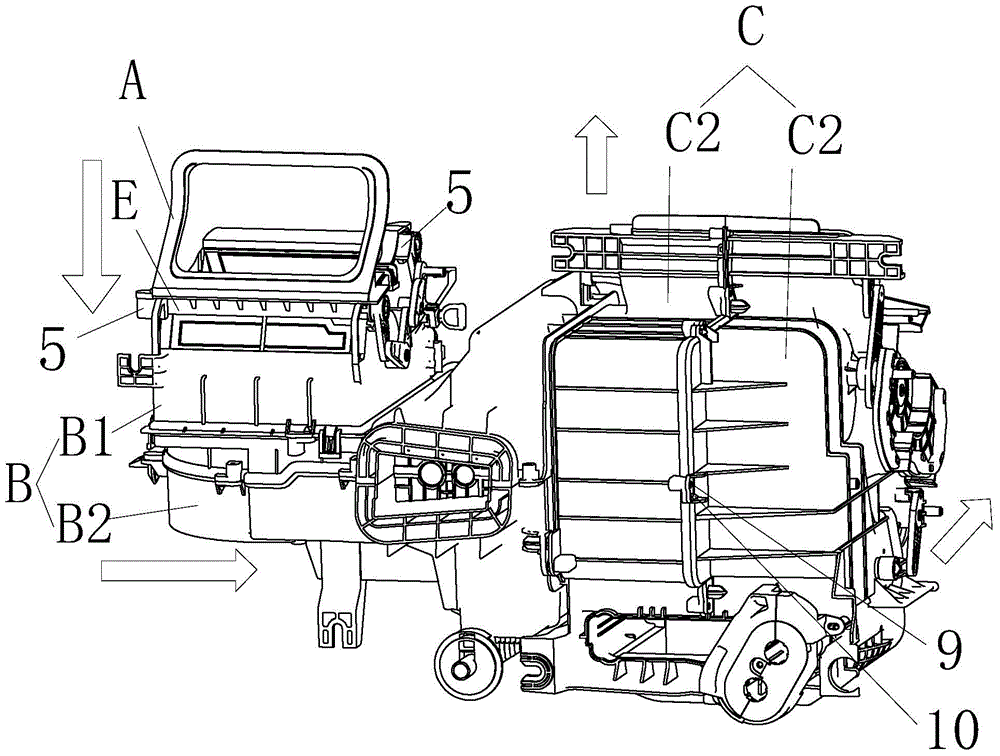

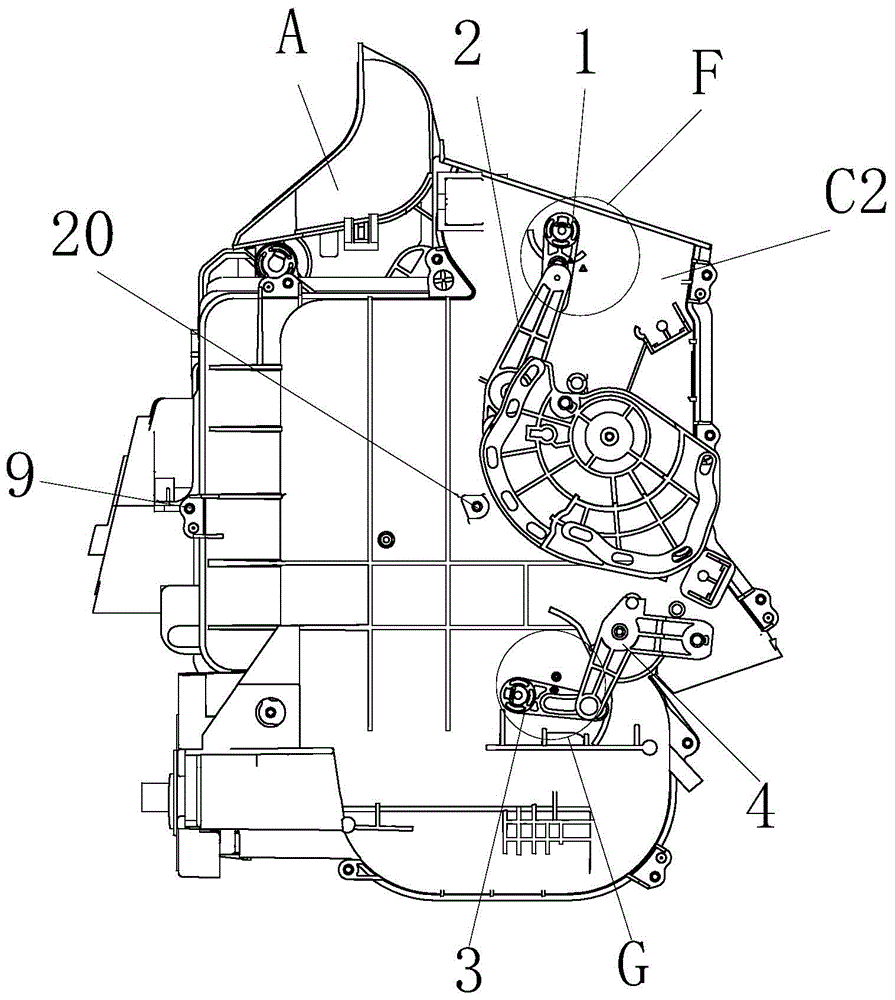

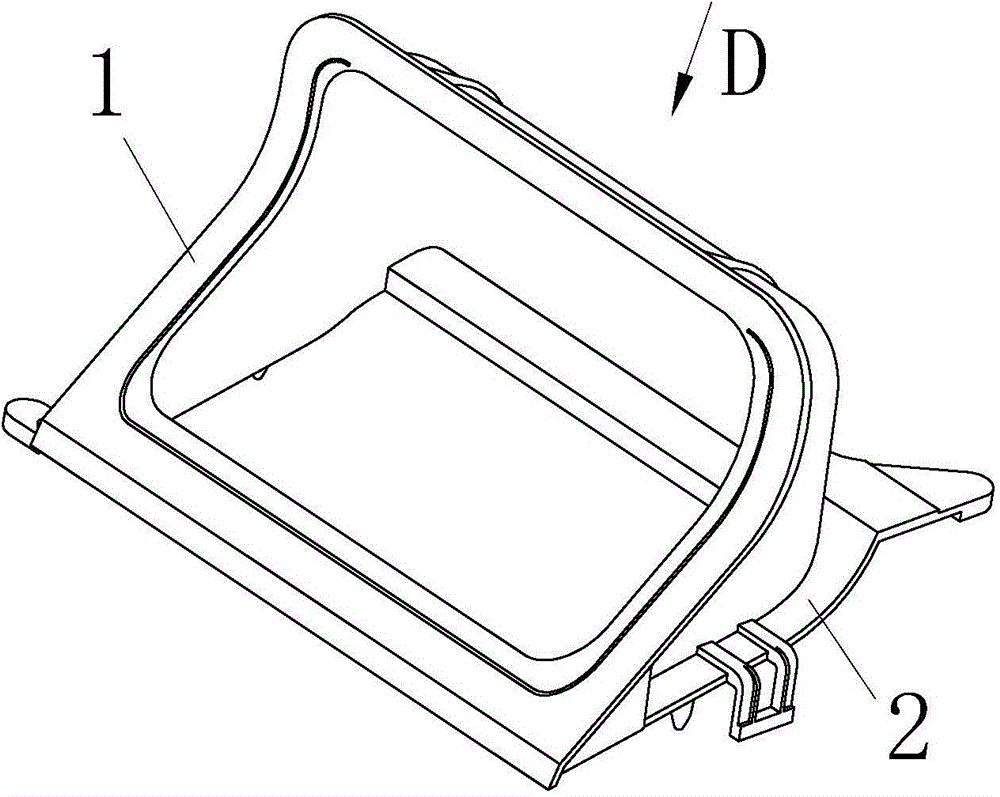

[0035] combine figure 1 —— figure 2As shown, a front steam assembly of an automobile air conditioner system is composed of a connecting air duct A, an air intake box housing E, an upper and lower housing assembly B, and a left and right housing assembly C, etc. connected in sequence. The connecting air duct A, the air inlet box housing E, and the upper and lower housing components B are arranged in sequence from top to bottom. The left and right housing assemblies C are located on the right side of the upper and lower housing assemblies B.

[0036] The upper and lower shell assembly B is composed of an upper shell B1 and a lower shell B2, and the upper shell B1 is located above the lower shell B2. The left and right case assembly C is composed of a left case C1 and a right case C2, and the left case C1 is located on the left side of the right case C2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com