Multiple-end face combined type mechanical seal for realizing zero leakage and non-contact

A mechanical seal, multi-face technology, used in engine seals, mechanical equipment, engine components, etc., can solve problems such as serious wear on the end face and unsatisfactory sealing performance, preventing leakage and improving lubrication conditions. and heat dissipation, improve the effect of friction and lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The end face micro-modeling in the present invention can be processed by electric spark, electrochemical corrosion, laser processing and other processes.

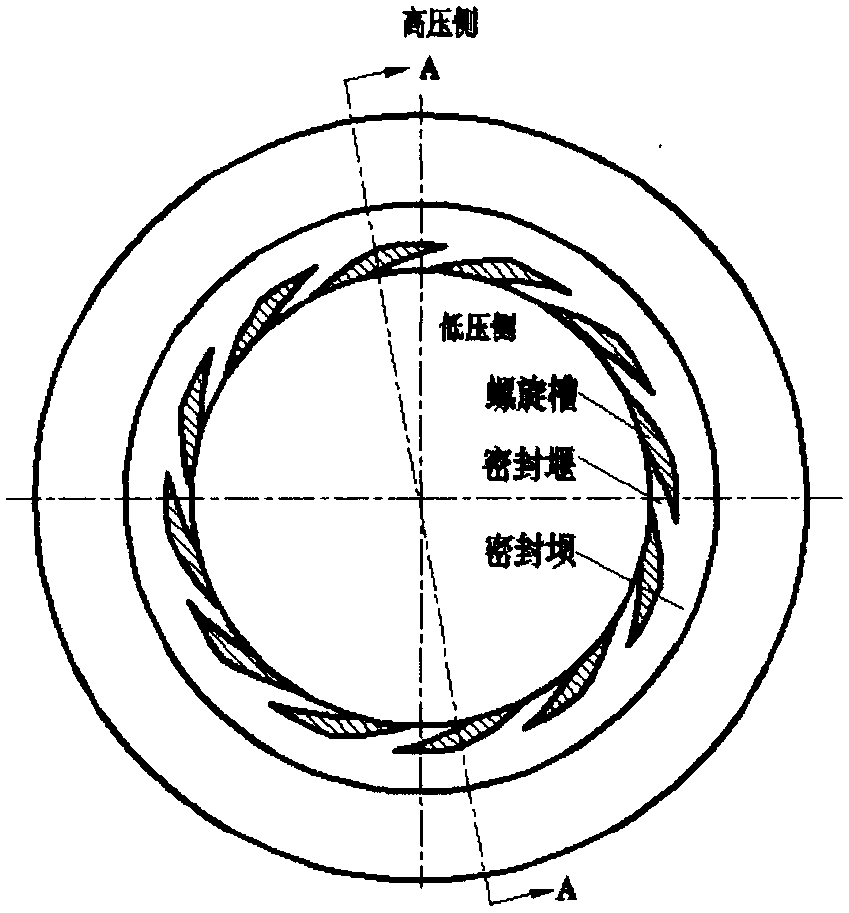

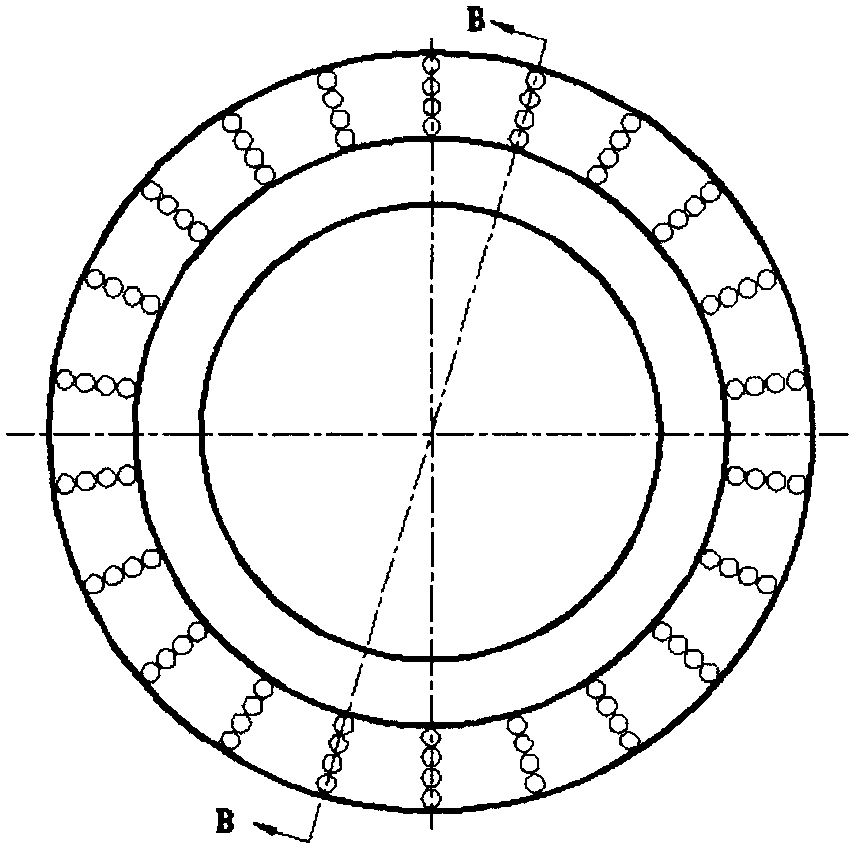

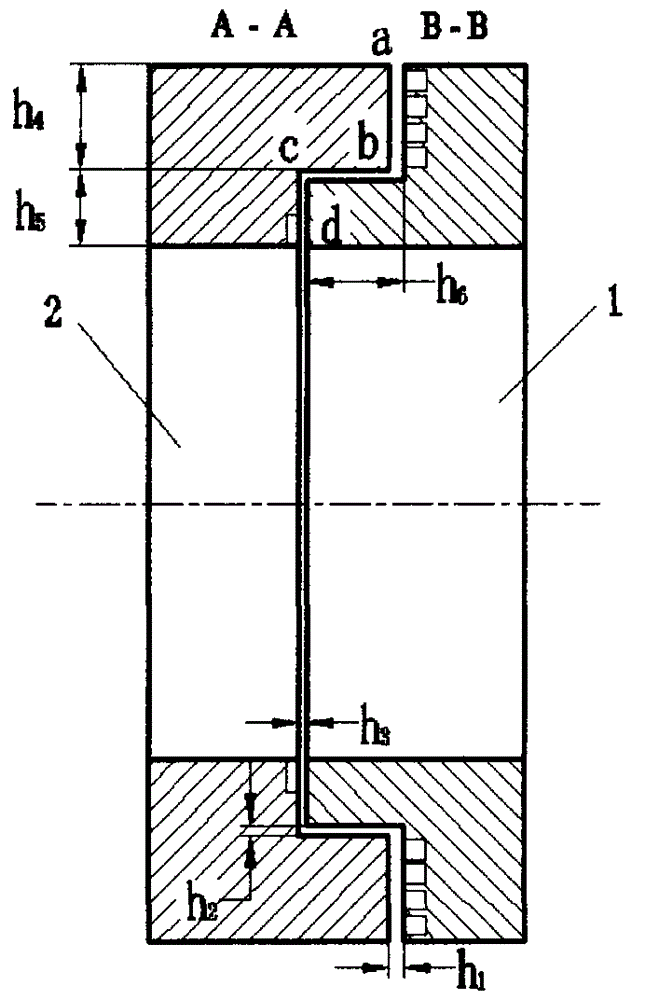

[0015] On the end face of the mechanical seal dynamic ring, there are pumping spiral grooves symmetrically distributed along the rotation center, such as figure 1 As shown; the groove is opened on the c-d surface, the groove depth is 5-10 μm, the number of grooves is 6-20, and the distance h between the moving ring and the static ring is assembled by the end surface of the outer diameter 1 than h 3 Larger than 4 ~ 10μm, h 4 with h 5 The ratio of the ratio is 1 to 1.5 times; on the end face of the static ring, open micro-holes uniformly distributed along the circumferential and radial directions, such as figure 2 Shown; the number of columns of microholes is n=12~30, the depth of microholes is h=5~20μm, the radius r=20~50μm, and the static ring extends out of the step h 6 4~8mm, the assembly diagram of the dynami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com