Hydraulic test system of well control device for oil and gas fields

A hydraulic test, oil and gas field technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problems of difficult control of the pressure test process, lack of spare parts, and less collection of pressure test information, and achieve remote rapid The effect of stepless modulation, ensuring safety and avoiding the dangerous phenomenon of overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

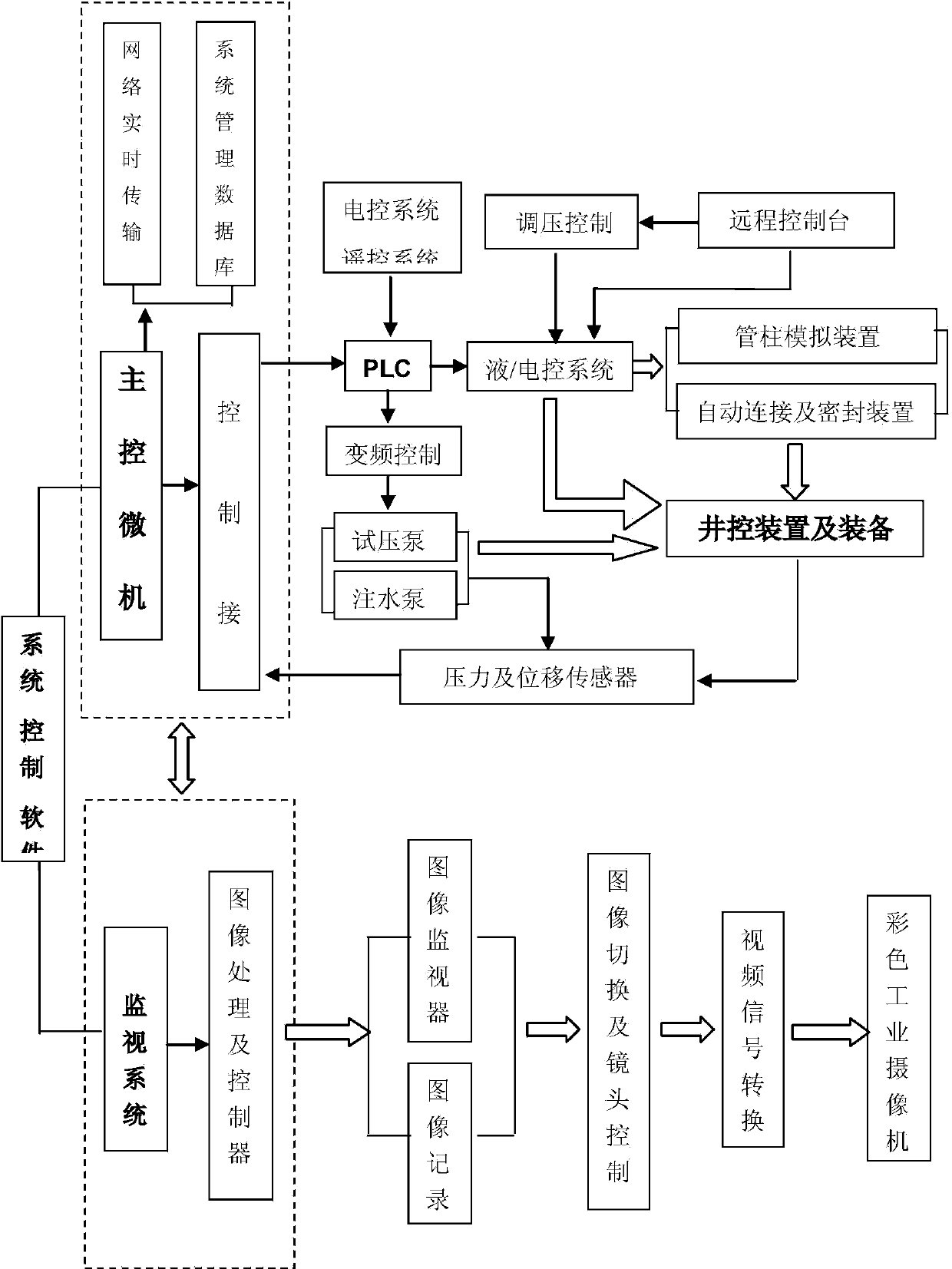

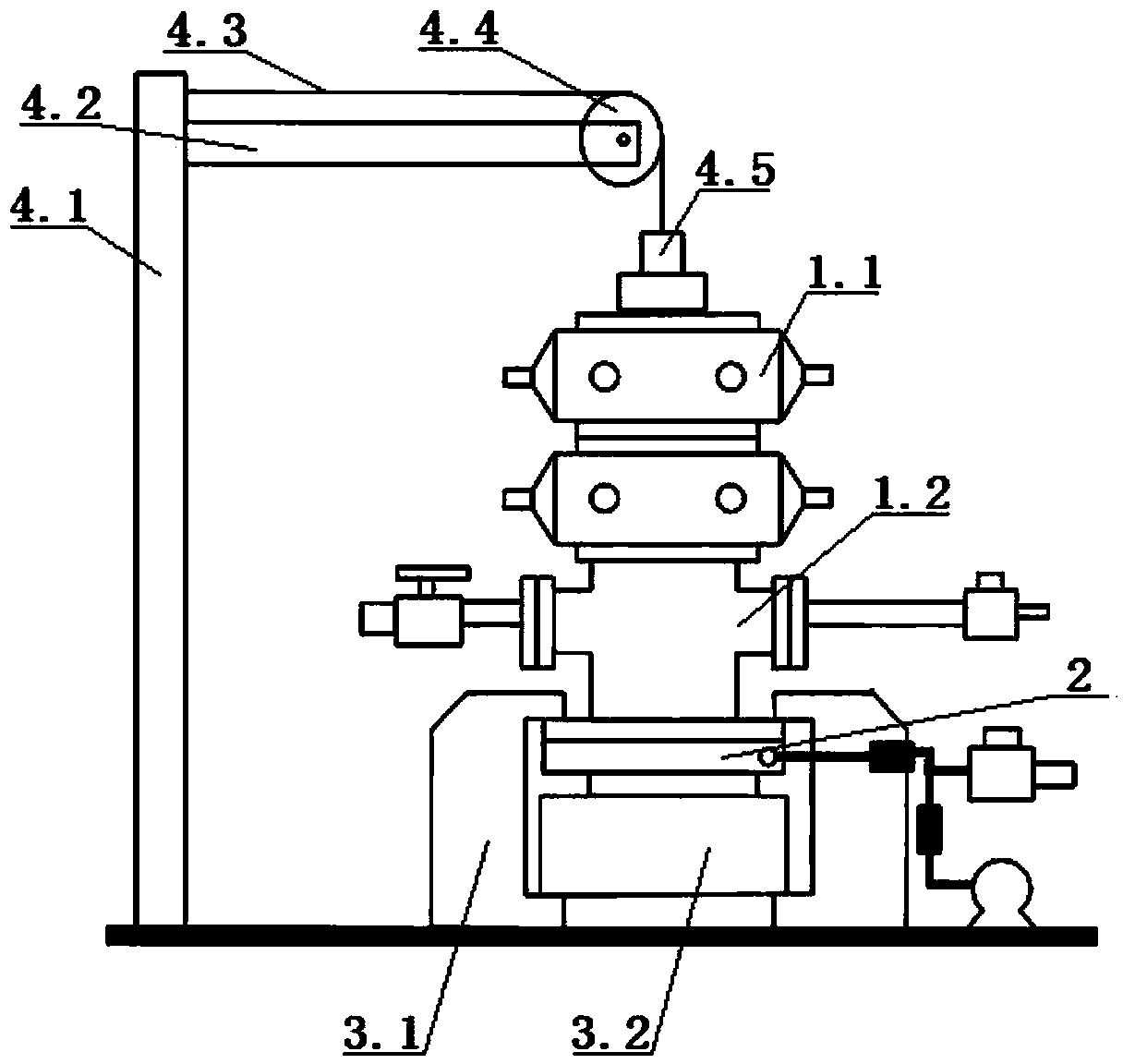

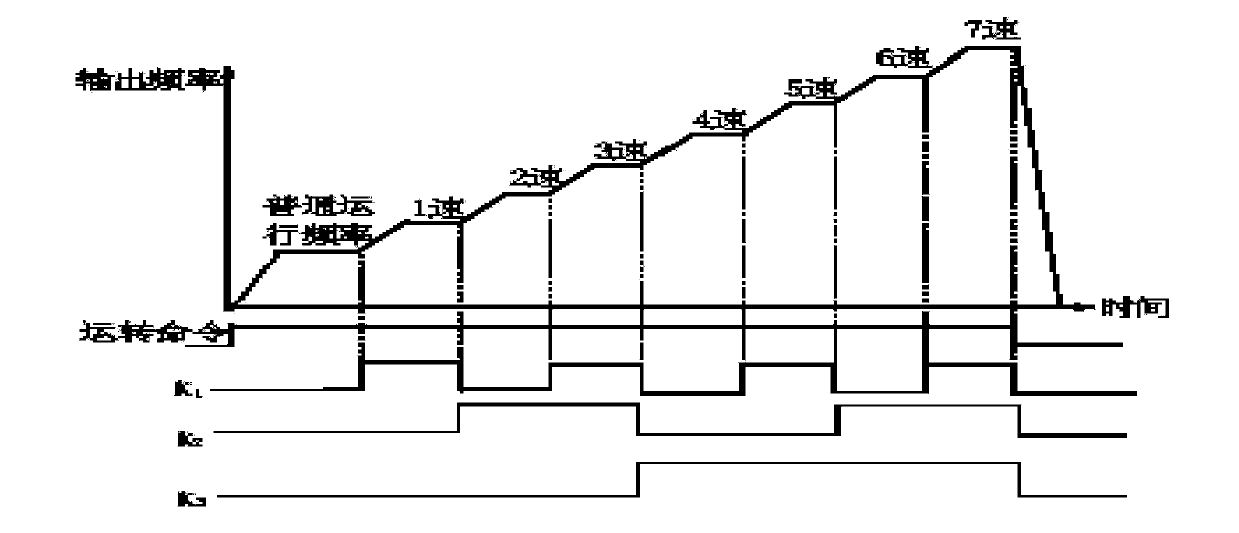

[0048] Main research content of the present invention

[0049] a. The index formulation and overall scheme design of the overall technology of the well control equipment pressure test monitoring and automatic data acquisition system. Aiming at the deficiencies and defects of similar systems at home and abroad, as well as the purpose and content of pressure testing of well control devices, design the technical indicators of the system and the overall plan for realizing the indicators.

[0050] b. Design of pressure test monitoring and monitoring control system. The safety of the pressure test process is very important. Since the ultra-high pressure in the pressure test process does not allow operators to approach, one of the research purposes of this project is to design all-round, whole-process remote monitoring and control, so that the pressure test process can realize remote visual monitoring and key image recording. Ensure the safety of personnel during the pressure test....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com