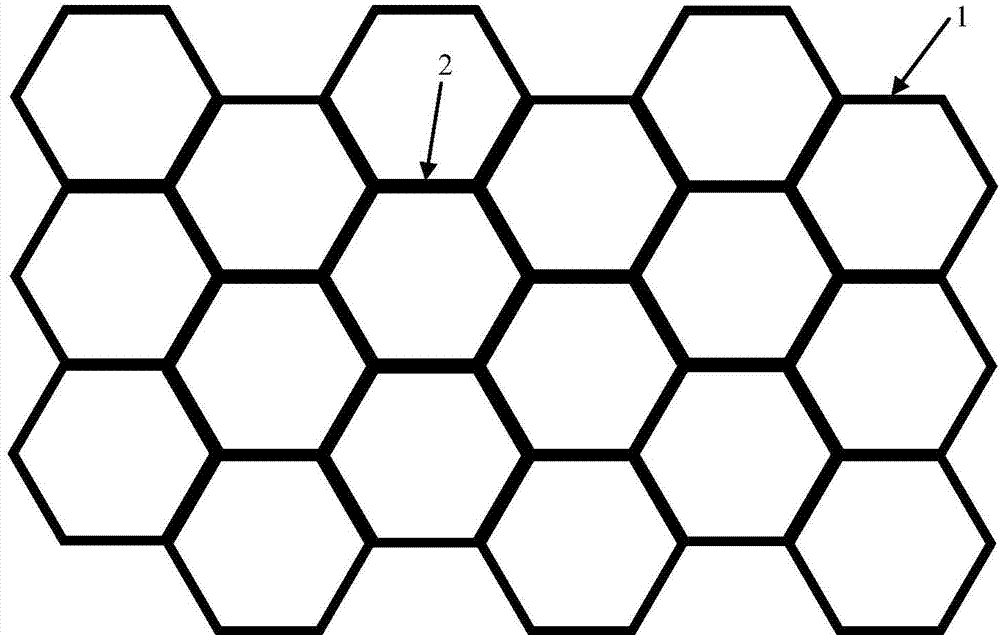

Honeycomb reinforced material

A reinforced material, honeycomb-like technology, applied in water conservancy projects, artificial islands, roads, etc., can solve the problems of soil filling constraints, low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

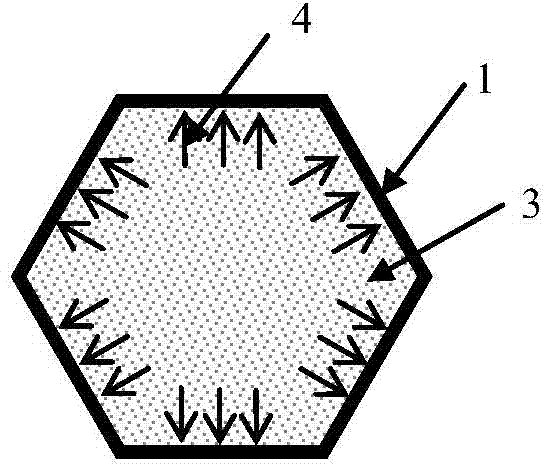

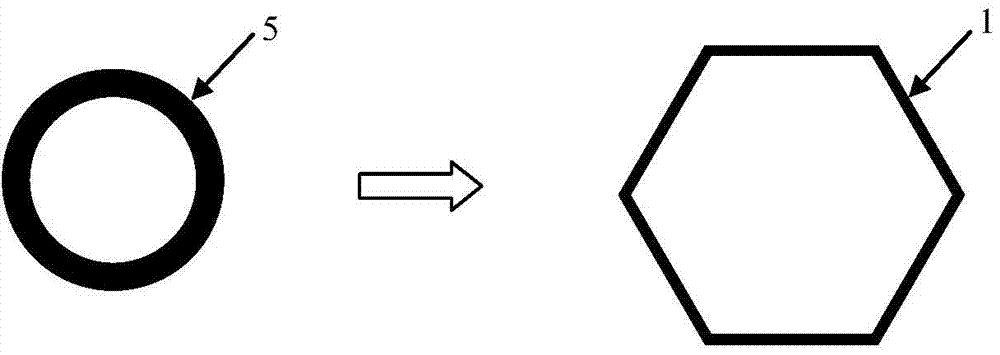

[0019] Firstly, the ring-shaped reinforced base metal is stretched, and the tension can be pushed by the mold or stretched in six directions at the same time. The strength of the reinforced material is improved by stretching, and at the same time, the circular reinforced base material is changed into a honeycomb hexagonal reinforced unit with a hexagonal plane size and a circular cross section, and all the honeycomb hexagonal reinforced The rib units are welded at adjacent sides in the plane to form a honeycomb reinforced material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com