Preparation method of vanadium dioxide nano rodlike thin film

A nano-rod-shaped, vanadium dioxide technology, applied in nanotechnology, electrolytic inorganic material coating and other directions, can solve the problems of difficult control of film thickness and uniform compactness, increase production costs, and accurately control parameters, etc. The effect of controllable thickness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Mix ethanol and deionized water evenly at a volume ratio of 1:1, dissolve vanadyl sulfate in it, and make a 0.2mol / L electrolyte;

[0030] 2. Add an appropriate amount of dispersant, stir for 15 minutes, and ultrasonically disperse for 20 minutes to obtain a blue clear solution;

[0031] 3. Add acid and alkali dropwise to adjust the pH value of the above solution to 2.5-2.7;

[0032] 4. Wash and dry the SnO2 transparent conductive glass (FTO) substrate doped with fluorine through appropriate amount of ethanol, acetone, hydrochloric acid and deionized water in sequence;

[0033] 5. Put the above-mentioned substrate and electrodes into the electrolyte in parallel at a distance of 2 cm, apply a DC voltage of 1.3 V, and power on for 20 minutes to perform electrochemical deposition coating;

[0034] 6. After the deposition, the product was dried at 80°C for 30 minutes, and then annealed at 500°C for 12 hours in an N2 atmosphere to obtain a brown film.

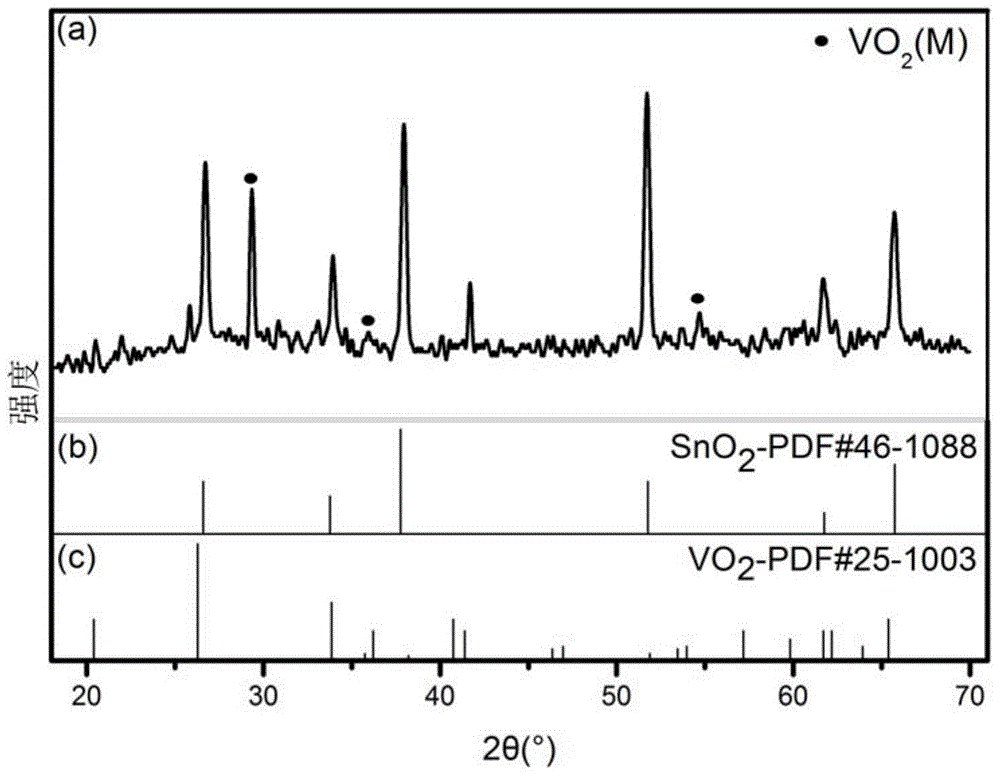

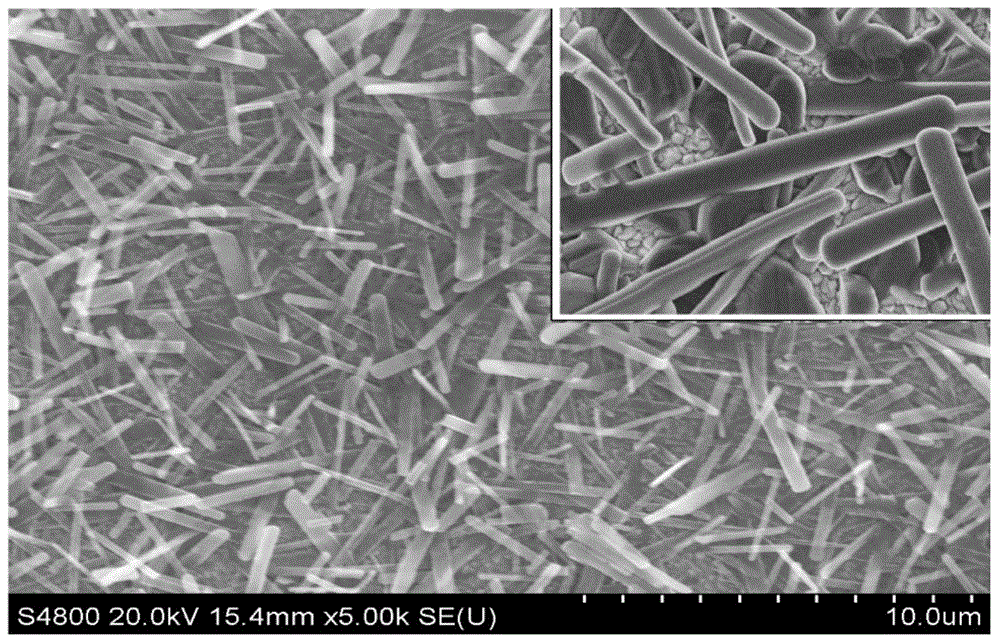

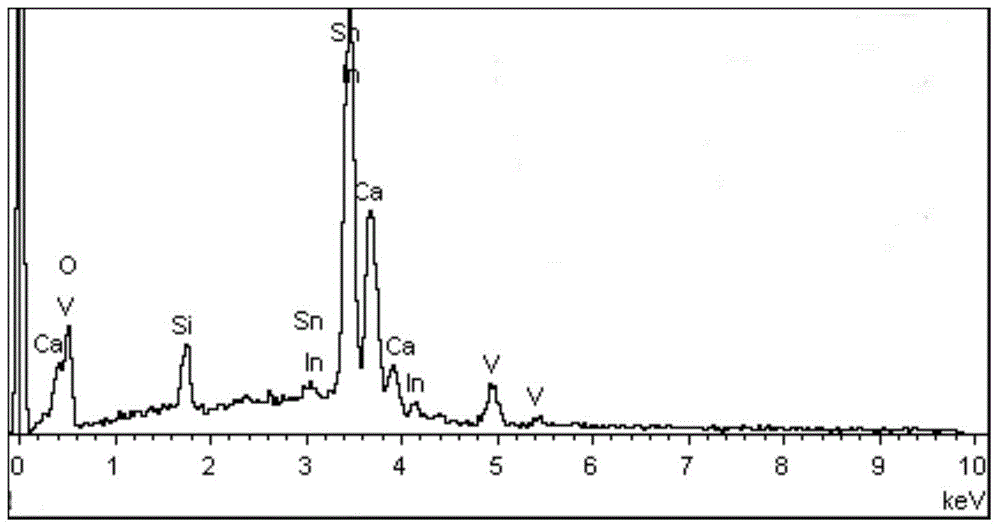

[0035] The XRD s...

Embodiment 2

[0038] Steps 1-4 are the same as in Example 1, the voltage in step 5 is 1.4V, the power-on time is 20min, and the annealing temperature in step 6 is 500°C.

[0039] The morphology of the vanadium dioxide nanorod film obtained in this example is consistent with that described in Example 1.

Embodiment 3

[0041] Steps 1-4 are the same as in Example 1, the voltage in step 5 is 1.3V, the power-on time is 60min, and the annealing temperature in step 6 is 500°C.

[0042] The morphology of the vanadium dioxide nanorod film obtained in this example is consistent with that described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com