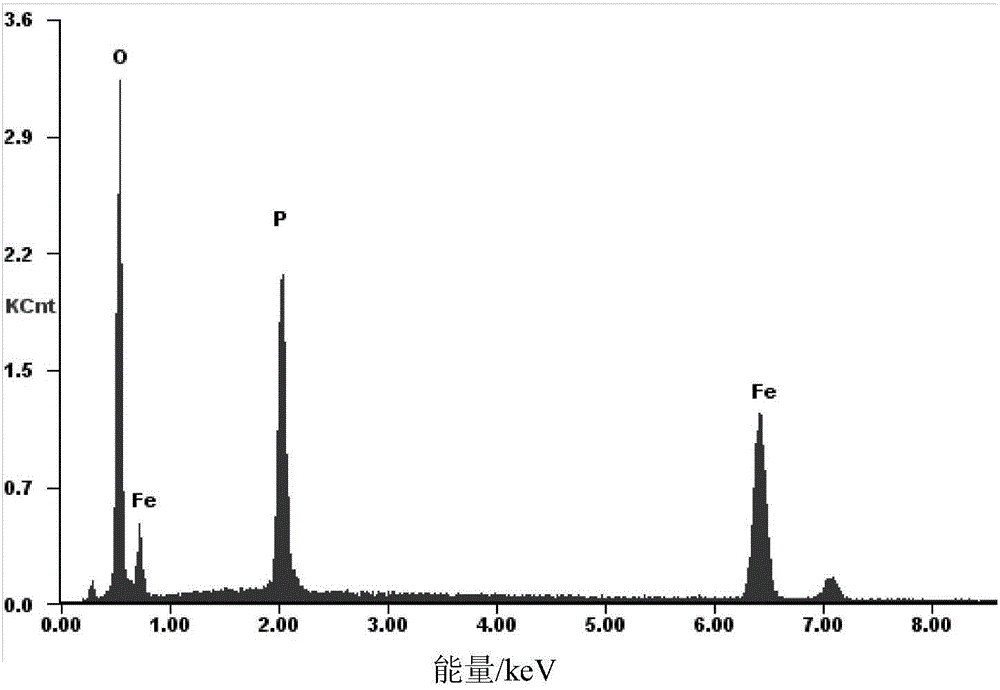

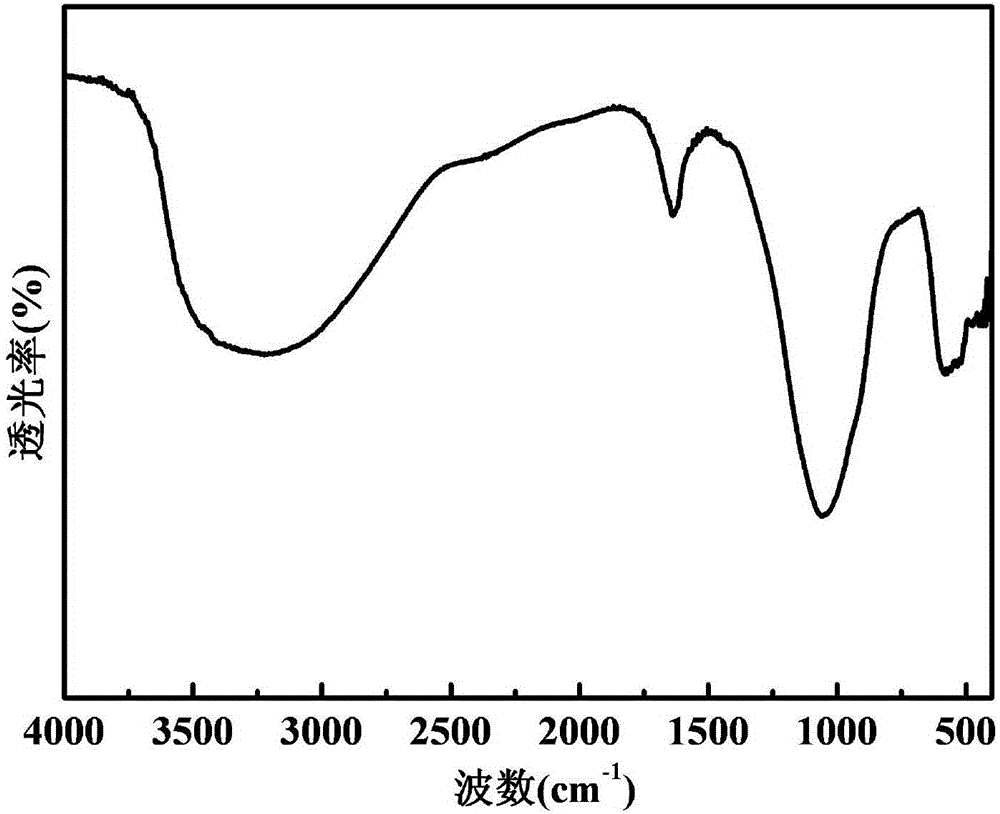

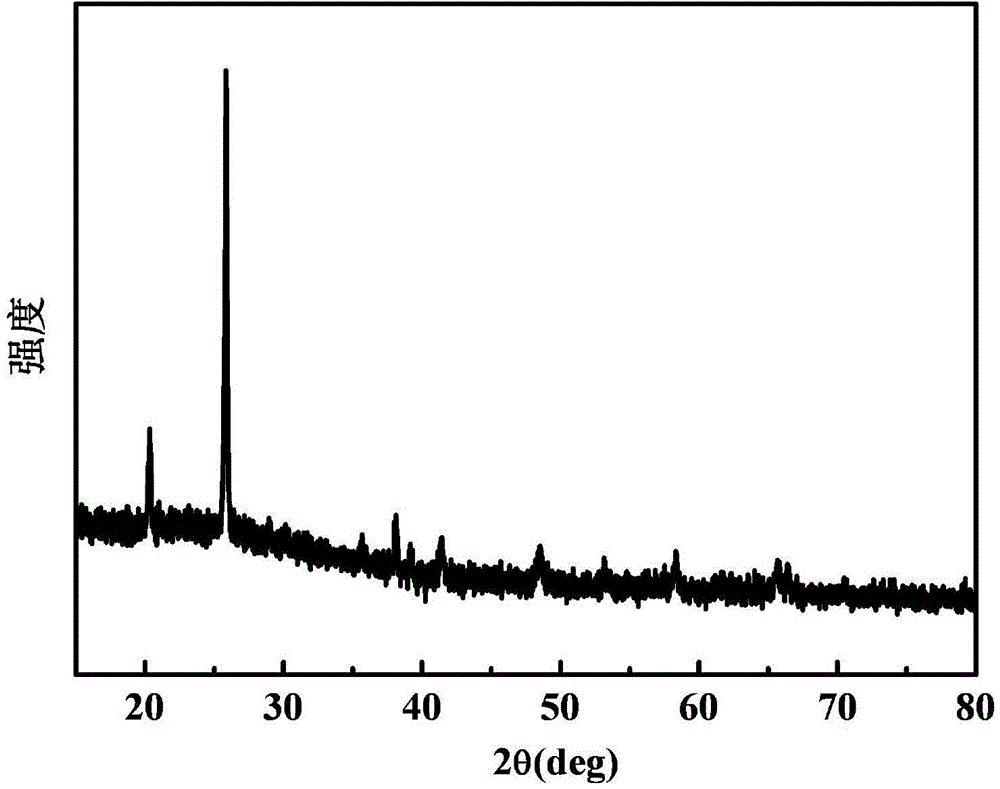

Dandelion-shaped iron phosphate microspheres and preparation method thereof through electrochemical anode oxidation

An anodic oxidation method, dandelion-shaped technology, applied in electrolysis process, electrolysis components, etc., can solve the problems of high synthesis temperature, complicated operation steps, and long synthesis time of iron phosphate micro-nano particles, so as to reduce the synthesis temperature and shorten the synthesis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: In this embodiment, a method for preparing dandelion-shaped iron phosphate microspheres by electrochemical anodic oxidation is carried out according to the following steps:

[0015] 1. Cut high-purity iron foil (≥99.5%) into appropriate size;

[0016] 2. Ultrasonic cleaning of high-purity iron foil with chloroform, ethanol and deionized water respectively, and removing surface oil and impurities 2 Carry out drying treatment in middle to achieve full drying;

[0017] 3. Prepare a solution with a molar concentration ratio of phosphoric acid and ammonium fluoride of (50-10):1 as the electrolyte for anodic oxidation, and then add alkali to adjust the pH value to 2-3, wherein the ammonium fluoride concentration is less than 0.1mol / L;

[0018] 4. Use the high-purity iron foil in step 2 as the anode and the platinum wire as the cathode, add an appropriate volume of prepared electrolyte, connect the power supply, and form an electrolytic cell;

[00...

specific Embodiment approach 2

[0021] Embodiment 2: A method for preparing dandelion-shaped iron phosphate microspheres by electrochemical anodic oxidation in this embodiment differs from Embodiment 1 in that the size of the high-purity iron foil in step 1 is 0.1 mm thick and 1 cm long. , 1cm wide. The rest are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: A method for preparing dandelion-shaped iron phosphate microspheres by electrochemical anodization in this embodiment differs from Embodiment 1 in that the distance between the two electrodes in step 4 is 1.5 cm to 2 cm. The rest are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com