A kind of carbon-based proppant and preparation method thereof

A proppant and carbon-based technology, applied in chemical instruments and methods, earthwork drilling, mining fluids, etc., can solve the problems of low strength, high energy consumption of proppant, complicated manufacturing process, etc., and achieve high temperature resistance and long-term diversion performance , Improve the anti-breaking ability, and the effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

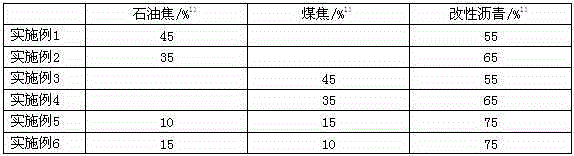

Embodiment 1

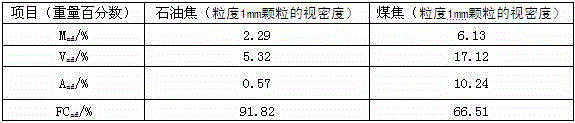

[0070] Step 1: Crushing and sieving the coke powder to obtain aggregates with a particle size of 106-425 μm;

[0071] Step 2: Put the aggregate into the impregnation kettle, heat to 100°C, vacuumize for 2 hours, and the vacuum degree is 8000Pa;

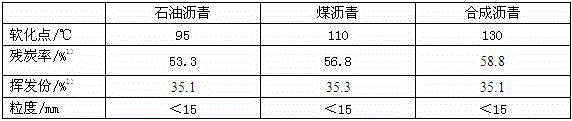

[0072] Step 3: Add asphalt and modifier in proportion to the preparation kettle, stir, heat to 120°C, and stay for 1 hour to make modified asphalt;

[0073] Step 4: Add the modified asphalt to the impregnation tank in proportion, and discharge the modified asphalt after impregnation to obtain the impregnating material;

[0074] Step 5: Cool the impregnation material, add a release agent at the same temperature, the weight ratio of the release agent to the impregnation material is 1:1, perform the isolation process, start stirring, cool after the stirring is completed, discharge the release agent, and obtain raw meal particles;

[0075] Step 6: Put the raw material granules in a curing furnace to dry and solidify in the air under norm...

Embodiment 2

[0078] Step 1: Sieve the coal semi-coke to obtain aggregates with a particle size of 106-425 μm;

[0079] Step 2: Add the aggregate to the impregnation kettle, heat to 116°C, vacuumize for 1.2h, and the vacuum degree is 980Pa;

[0080] Step 3: Add asphalt and modifier in proportion to the preparation kettle, stir, heat to 125°C, and stay for 0.5h to make modified asphalt;

[0081] Step 4: Add the modified asphalt to the impregnation tank in proportion, and discharge the modified asphalt after impregnation to obtain the impregnating material;

[0082] Step 5: Cool the impregnation material, add a release agent at the same temperature, the weight ratio of the release agent to the impregnation material is 2:1, perform the isolation process, start stirring, cool after the stirring is completed, discharge the release agent, and obtain raw meal particles;

[0083] Step 6: Put the raw material granules in a curing furnace to dry and solidify in the air under normal pressure to sligh...

Embodiment 3

[0086] Step 1: Crushing and sieving coke powder and coal semi-coke to obtain aggregates with a particle size of 425-850 μm;

[0087] Step 2: Put the aggregate into the impregnation kettle, heat to 130°C, vacuumize for 1.2h, and the vacuum degree is 2580Pa;

[0088] Step 3: Add asphalt and modifier in proportion to the preparation kettle, stir, heat to 140°C, and stay for 0.6h to make modified asphalt;

[0089] Step 4: Add the modified asphalt to the impregnation tank in proportion, and discharge the modified asphalt after impregnation to obtain the impregnating material;

[0090] Step 5: Cool the impregnation material, add a release agent at the same temperature, the weight ratio of the release agent to the impregnation material is 1.2:1, perform the isolation process, start stirring, cool after the stirring is completed, discharge the release agent, and obtain raw meal particles;

[0091] Step 6: Put the raw material granules in a curing furnace to dry and solidify in the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com