Humidity-heat resistant cyanacrylate adhesive

A technology of cyanoacrylate and polymerization inhibitor, which is used in adhesives, polymer adhesive additives, non-polymer organic compound adhesives, etc., can solve the problems of poor heat and water resistance, limitations and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

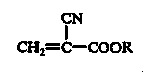

Method used

Image

Examples

Embodiment 1

[0029] Add 0.1% free radical stabilizer hydroquinone, 0.05% anion stabilizer p-toluenesulfonic acid, and 0.5% accelerator dimethylsila-11-crown-4 to ethyl cyanoacrylate , 10% polymethyl methacrylate (PMMA), polyvinyl acetate (PVAC), vinyl acrylate rubber (AEM), nitrile rubber (NBR), acrylonitrile-butadiene-styrene copolymer ( ABS), acrylonitrile-styrene-acrylic rubber copolymer (ASA), stirred at 55-65°C for 1-2h to obtain glue. Test the positioning time of the glue on the nitrile rubber, and test the shear strength of the glue bonded carbon steel sheet according to the GB / T7124-2008 method. ℃, 90%RH in these two environments, test the shear strength of aging for 168h, so as to evaluate the moisture and heat resistance of the glue. The results are shown in the following table, where the percentage in the damp heat aging data is the relative 24h shear strength retention rate, and sample No. 1 is the blank sample:

[0030]

[0031] Compared with linear polymers PMMA and PVAC...

Embodiment 2

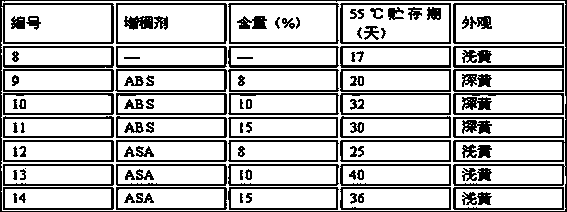

[0032] Add 0.1% free radical stabilizer hydroquinone, 0.05% anion stabilizer p-toluenesulfonic acid, and 0.5% accelerator dimethylsila-11-crown-4 to ethyl cyanoacrylate , different contents of ABS and ASA, and investigate the storage period of the prepared glue solution at 55°C (the maximum number of days for the glue solution not to thicken or solidify significantly) and the appearance change. Sample No. 8 is a blank sample.

[0033]

[0034] Compared with ABS, the addition of ASA can effectively improve the stability of ethyl α-cyanoacrylate, and the ideal addition amount is 10%.

[0035] Embodiment two:

[0036] Add 10% ASA or PMMA, 0.1% free radical stabilizer hydroquinone, 0.05% anion stabilizer p-toluenesulfonic acid, 0.5% anion stabilizer to methyl cyanoacrylate and ethyl cyanoacrylate respectively. % accelerator dimethylsila-11-crown-4. According to the method of GB / T 2791-1995, the peel strength of the aluminum sheet bonded by the glue is tested. Sample Nos. 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com