Preparation method of low-smoke-density halogen-free flame retardant cable material

A flame retardant cable material, smoke density technology, applied in circuits, electrical components, plastic/resin/wax insulators and other directions, can solve the problems of poor compatibility, difficult processing, and the mechanical and mechanical properties of fuel resistance cannot meet the requirements. Achieve good flame retardant and mechanical properties, good interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

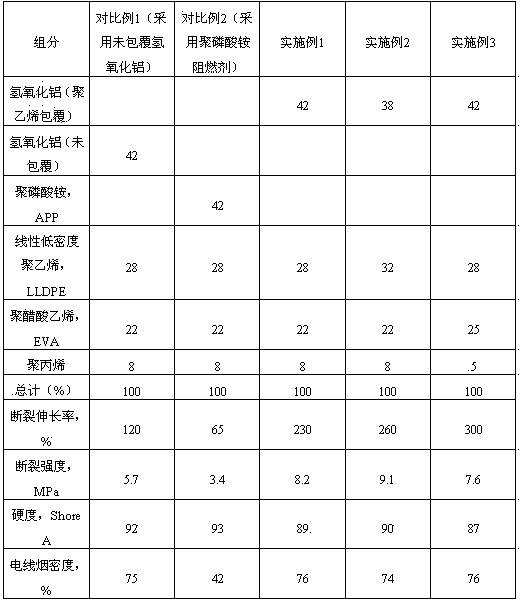

Embodiment 1~ Embodiment 3

[0021] Embodiment 1 ~ embodiment 3 cable material preparation method is as follows:

[0022] Put aluminum hydroxide (97wt%, Japan Showa product, model H-42M), antioxidant 1010 (1.5wt%, BASF product) and dispersant KH570 (1.5wt%, Nanjing Qianqian chemical product) in a high mixer Mix at 1200 rpm for 5 minutes, and the mixing temperature is 60°C; add the above-mentioned aluminum hydroxide mixed with additives and linear low-density polyethylene into the single-screw extruder from different feeders according to the weight ratio of 97:3 , fully mixed and granulated, wherein the feeder speed is 30 kg / h, and the process parameters of the single-screw extruder are set as: processing temperature 160 ° C, melt temperature < 200 ° C, air-cut granulation; vacuum dryer Dry at 105°C for 6 hours to obtain polyethylene-coated aluminum hydroxide flame retardant particles; mix polyethylene, polyvinyl acetate, polypropylene, and the above polyethylene-coated aluminum hydroxide Flame retardant ...

Embodiment 1

[0027] Compared with Example 2, Example 1 appropriately reduces the content of coated aluminum hydroxide and increases the content of resin, which can improve the mechanical properties of the material, which is reflected in the increase of elongation at break and strength at break.

[0028] Compared with Example 1 and Example 3, increasing the content of polyvinyl acetate can further improve the interfacial compatibility between the resin and the flame retardant, and increase the elongation at break. However, due to the increase of the flexible structure in the material, its fracture strength decreased.

[0029] To sum up, the cable material prepared by the present invention can meet the requirement of low smoke density, and has good flame retardancy and mechanical properties at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com