Pigment dispersion resin used for acrylic series cathode electrophoretic coating and pigment slurry thereof

A cathodic electrophoretic coating and acrylic resin technology, applied in the field of pigment dispersion resin and pigment paste, can solve the problems of failing to meet application requirements, rough paint film, poor compatibility, etc., and achieve excellent test results, good effects, and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of quaternizing agent A-1

[0021] The quaternizing agent of the present invention is the reaction product of a tertiary amine compound containing active hydrogen and a partially blocked polyisocyanate, which is neutralized with an organic acid. The molar ratio of -NCO group in polyisocyanate is 1.0~2.0:1, and its partially blocked polyisocyanate uses one or more of alcohols, alcohol ethers, alcohols and alcohol ether mixtures as blocking agents and at least It is formed by the reaction of a polyisocyanate compound containing two isocyanate groups. During the reaction, the molar ratio of the -OH group of the blocking agent to the -NCO group of the polyisocyanate compound is 0.5-0.8:1.

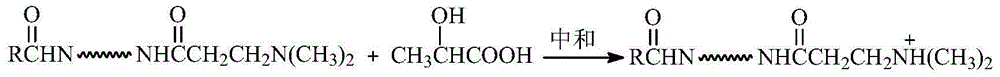

[0022] ①The chemical reaction formula involved in the preparation of quaternizing agent

[0023]

[0024]

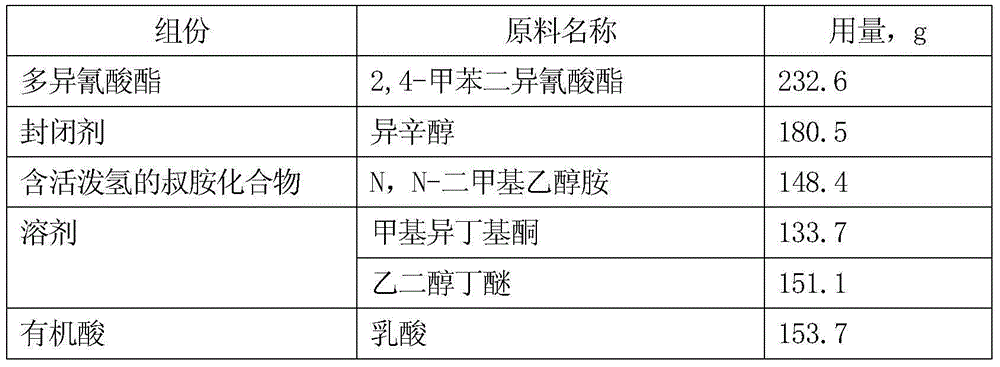

[0025] ② The raw material formula is listed in Table 1

[0026] Table 1

[0027]

[0028] Note 1: The molar ratio of the -OH group of the active hydroge...

Embodiment 2

[0054] (1) Preparation of quaternizing agent A-2

[0055] 1. The chemical reaction formula involved in the preparation of the quaternizing agent is the same as in Example 1.

[0056] ② The raw material formula is listed in Table 4

[0057] Table 4

[0058]

[0059] Note 1: The molar ratio of the -OH group of the active hydrogen-containing tertiary amine compound to the NCO group in the partially blocked polyisocyanate is 1:1;

[0060] Note 2: The molar ratio of the -OH group of the blocking agent to the -NCO group of the polyisocyanate compound is 0.5:1.

[0061] ③ The preparation process was the same as in Example 1, and the quaternizing agent A-2 (active hydrogen equivalent 700) was prepared, which was stored for future use.

[0062] (2) Preparation of acrylic resin B-2 containing epoxy groups

[0063] 1. The chemical reaction formula for preparing the acrylic resin containing epoxy groups is the same as in Example 1.

[0064] ② The raw material formula is listed in ...

Embodiment 3

[0079] Embodiment 3 prepares cathodic electrophoretic coating pigment slurry

[0080] The pigment slurry of the present invention is prepared by mixing the pigment dispersion resin of the present invention, at least one pigment, a powder metal catalyst and deionized water uniformly, and then grinding and dispersing to a fineness of ≤15 μm with a sand mill. The pigment slurry The solid content of the product is 30-60wt%, calculated as solids, the weight ratio of the pigment to the pigment dispersion resin is 1-10:1, and the powder metal catalyst accounts for 0.5-3% in the total weight of the pigment paste solids.

[0081] (1) Preparation of black pigment paste

[0082] ① The raw material formula is listed in Table 7

[0083] Table 7

[0084]

[0085] ②Preparation process

[0086] After mixing the above raw materials evenly, use a sand mill to grind and disperse to a fineness of ≤15 μm to obtain a black pigment slurry with a solid content of 45wt%. In terms of solids, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com