Bleaching method of metatitanic acid in titanium dioxide production by sulfuric acid method

A technology of metatitanic acid and titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of dangerous operation process, increased preparation workload, complicated preparation process, etc. High tinting strength and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

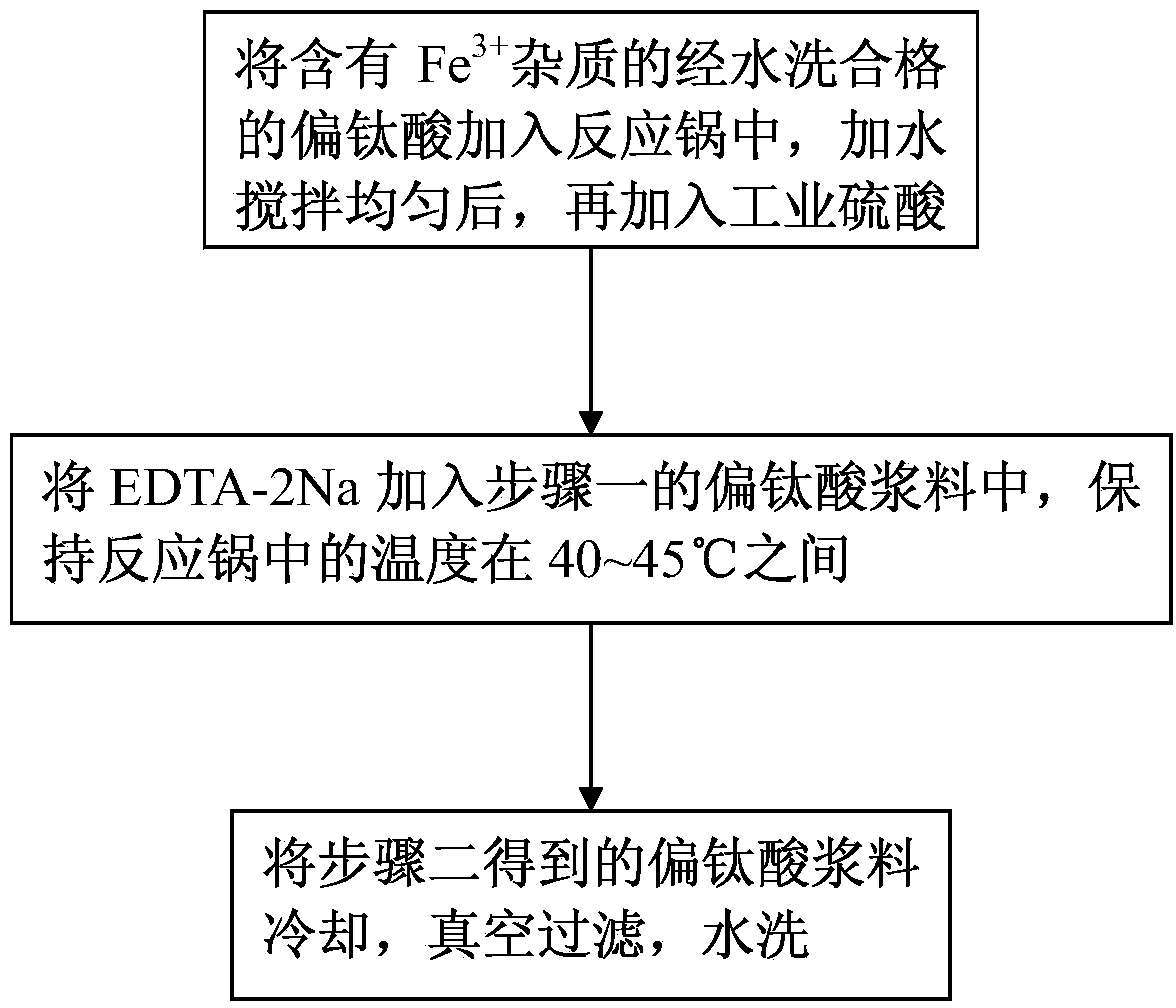

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Add water-washed qualified metatitanic acid and water into the enamel reaction pot heated by a jacket with stirring, and the trace iron impurities of metatitanic acid are represented by Fe 2 o 3 The content is 0.010%, stir and adjust the content of TiO in the metatitanic acid slurry 2 to 235g / L, then add a certain amount of industrial sulfuric acid to make the sulfuric acid concentration of the metatitanic acid slurry 35g / L, and heat it to 40°C with steam to dissolve ferric hydroxide into ferric sulfate solution;

[0040] Step 2. Press EDTA-2Na / Fe 3+ The molar ratio is 4:1. Weigh the complexing agent EDTA-2Na and add water to make a solution. Add it to the metatitanic acid slurry in batches while stirring, and continue heating to keep the temperature at 40°C for 1.5h. The ferric sulfate reacts completely with the complex EDTA-2Na to generate the corresponding ferric complex;

[0041] Step 3. Cool the metatitanic acid slurry after complexation and bleaching to...

Embodiment 2

[0046] Step 1. Add water-washed qualified metatitanic acid and water into the enamel reaction pot heated by a jacket with stirring, and the trace iron impurities of metatitanic acid are represented by Fe 2 o 3 The content is 0.008%, stir and adjust the content of TiO in the metatitanic acid slurry 2 to 245g / L, then add a certain amount of industrial sulfuric acid to make the sulfuric acid concentration of the metatitanic acid slurry 45g / L, and heat it to 45°C with steam to dissolve ferric hydroxide into ferric sulfate solution;

[0047] Step 2. Press EDTA-2Na / Fe 3+ The molar ratio is 3:1. Weigh the complexing agent EDTA-2Na and add water to make a solution. Add it to the metatitanic acid slurry in batches while stirring, and continue heating to keep the temperature at 45°C for 1h to make the sulfuric acid Ferric reacts completely with the complex EDTA-2Na to generate the corresponding ferric complex;

[0048] Step 3. Cool the metatitanic acid slurry after complexation and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com