A thermal-electrostatic strong recovery type mems four-point support suspension beam structure

A technology of four-point support and suspension beams, which is applied to televisions, generators/motors, and components of television systems, etc., can solve problems such as difficult recovery, increase effective stiffness, make the structure and method feasible, and improve recovery ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

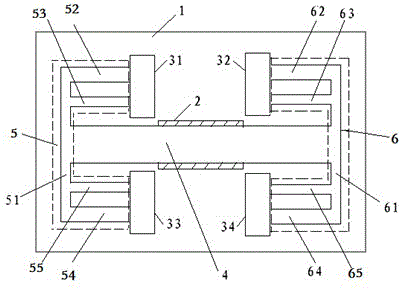

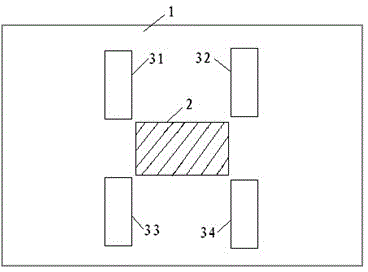

[0017] Such as figure 1 and figure 2 As shown, a thermal-static strong recovery type MEMS four-point support suspension beam structure of the present invention, the structure includes a substrate 1, a pull-down electrode 2 for electrostatic excitation, anchor areas 31-34, a suspension main beam 4, Bending support beams 5 and 6. The suspension main beam 4 is suspended above the substrate 1 through four anchor areas 31 , 32 , 33 , 34 and bending support beams 5 and 6 at both ends.

[0018] Such as figure 1 and figure 2 As shown, the bending support beam 5 is composed of a crossbeam 51 and two groups of parallel longitudinal beams 52 , 53 and 54 , 55 . Among them, the longitudinal beam adopts wide and narrow beam design, 52 and 54 are narrow beams, and 53 and 55 are wide beams. The bending support beam 6 at the other end is structurally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com