A preparation method of thermoplastic resin fiber unidirectional tape toughened unidirectional prepreg

A technology of thermoplastic resin and unidirectional tape, which is applied in the field of composite material prepreg preparation, can solve the problems affecting the process performance of composite materials, cumbersome process, and poor paving performance, so as to facilitate large-scale production and improve preparation efficiency , good glue penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

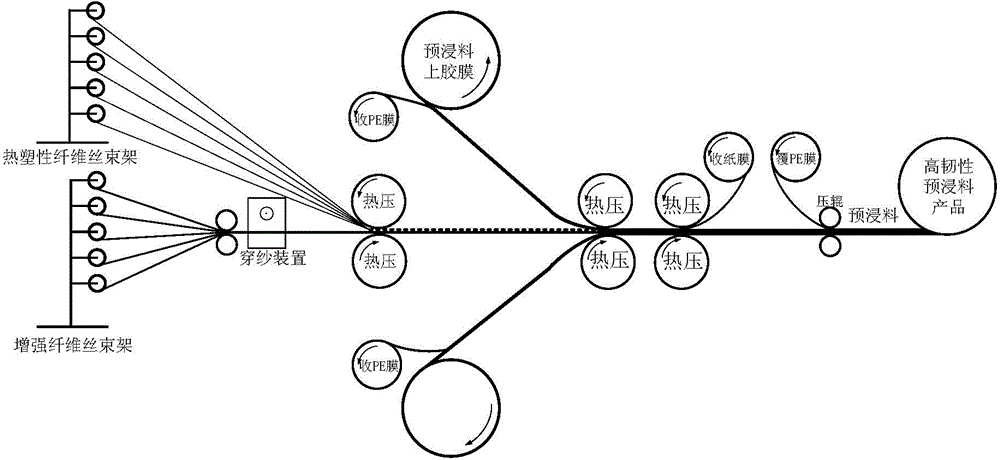

[0022] A preparation method of thermoplastic resin fiber unidirectional tape toughened prepreg, the specific steps are as follows:

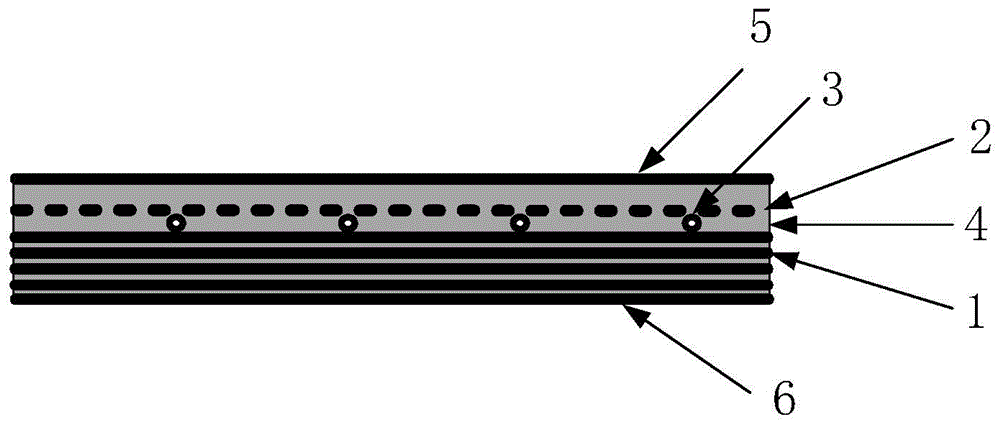

[0023] (1) According to the surface density requirements of the prepreg, arrange and unfold each bundle of reinforcing fibers drawn from the reinforcing fiber tow frame on the prepreg machine to form a reinforcing fiber unidirectional belt 1;

[0024] (2) Introduce the thermoplastic fiber tow above the reinforcing fiber of the prepreg machine, and spread it evenly to form a thermoplastic resin fiber unidirectional belt 2, and the surface density of the thermoplastic fiber unidirectional belt 2 is controlled at 10g / m 2 ~40g / m 2 , the thermoplastic fiber unidirectional belt 2 is equal in width to the reinforced fiber unidirectional belt 1, and aligned left and right, the thermoplastic fiber unidirectional belt 2 is located directly above the reinforced fiber unidirectional belt 1, and there is a gap between them;

[0025] (3) A threading device is...

Embodiment 1

[0029] Polyamide PA6 unidirectional fiber is selected as the toughening material, the average diameter of the fiber is about 5 μm, and CCF300 carbon fiber is used as the reinforcing material. After the CCF300 carbon fiber arrangement is completed, the PA6 fiber unidirectional tape is introduced to the surface of the CCF300 carbon fiber, and the surface density of the PA6 fiber unidirectional tape is controlled at 10g / m 2 . Every 25mm, the threading device crosses a bunch of PA6 fiber tows between the CCF300 carbon fiber unidirectional belt and the PA6 fiber unidirectional belt to prevent the PA6 fiber from being embedded in the carbon fiber and affecting the toughening effect. Then, the epoxy resin-based prepreg film is combined with PA6 fiber and CCF300 carbon fiber through a hot pressing roller to prepare a high-toughness prepreg product with PA6 fiber unidirectional tape toughening. After the release paper on the upper surface of the prepreg is peeled off and covered with ...

Embodiment 2

[0031] Polyethersulfone PES unidirectional fiber is selected as the toughening material, the average diameter of the fiber is about 15 μm, and T700 carbon fiber is used as the reinforcing material. After the T700 carbon fiber arrangement is completed, introduce the PES fiber unidirectional tape to the surface of the T700 carbon fiber, and the surface density of the PES fiber unidirectional tape is controlled at 10g / m 2 . Every 100mm, the threading device crosses a bunch of PES fiber tows between the T700 carbon fiber unidirectional belt and the PES fiber unidirectional belt to prevent the PES fiber from being embedded in the carbon fiber and affecting the toughening effect. Then, the epoxy resin-based prepreg film is combined with PES fiber and T700 carbon fiber through a hot pressing roller to prepare a high-toughness prepreg product with PES fiber unidirectional tape toughening. After the release paper on the upper surface of the prepreg is peeled off and covered with polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com