Processing method and special processing device for bionic syringe needle

A technology of injection needle and processing method, which is applied in the field of bionic syringe needle processing and special processing device, can solve the problems of reduced strength of injection needle, infection, easily broken needle on the skin, etc., and achieves the effect of preventing distortion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

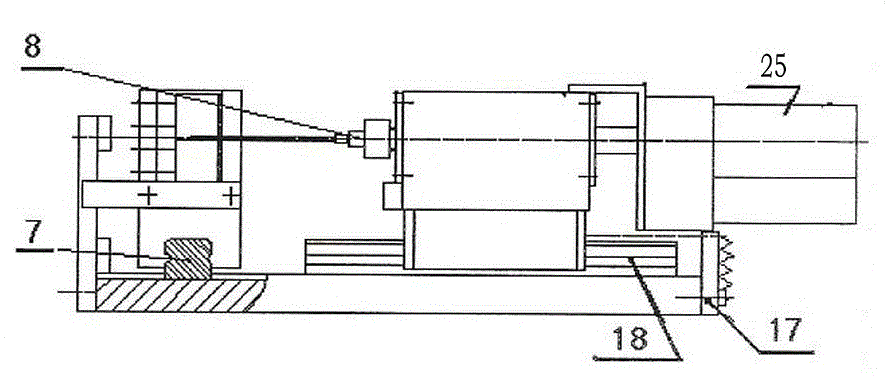

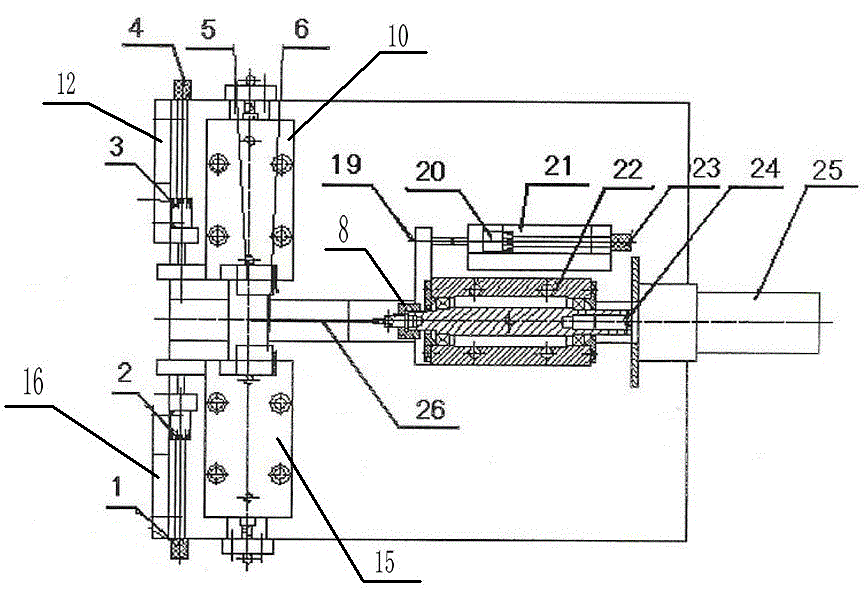

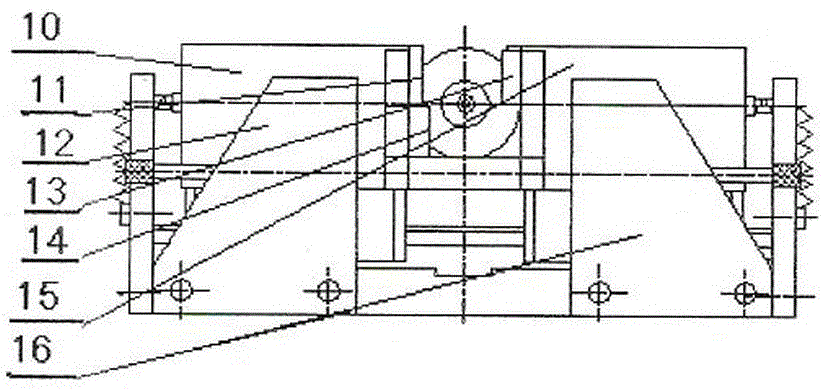

[0025] The method of the present invention comprises the following steps: refer to figure 1 , figure 2 and image 3 shown;

[0026] (1) Before processing the syringe needle 26, the tail of the syringe needle 26 is fixedly connected to the injection needle fixing device 8 in the front section of the fourth servo motor 25 of the chipless automatic rolling device. The injection needle fixing device 8 is connected to the fourth servo The motor 25 is coaxial and connected with the motor shaft as a whole, so that the rotation of the syringe needle 26 and the rotation of the fourth servo motor 25 can be completely synchronized during the processing. The fourth servo motor 25 and the injection needle fixing device 8 are connected to the straight second linear guide pair 18 through the fixed motor connection seat 22, and the third servo motor 23 controls its lateral feed rate and moving speed. The amount of lateral feed is based on the structural size of the center distance of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com