Coiling method of hot continuous rolling free plate

A free and reel technology, applied in metal rolling and other directions, can solve the problems of inability to achieve successful coiling of free plates, surface quality defects of titanium plates, large springback, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

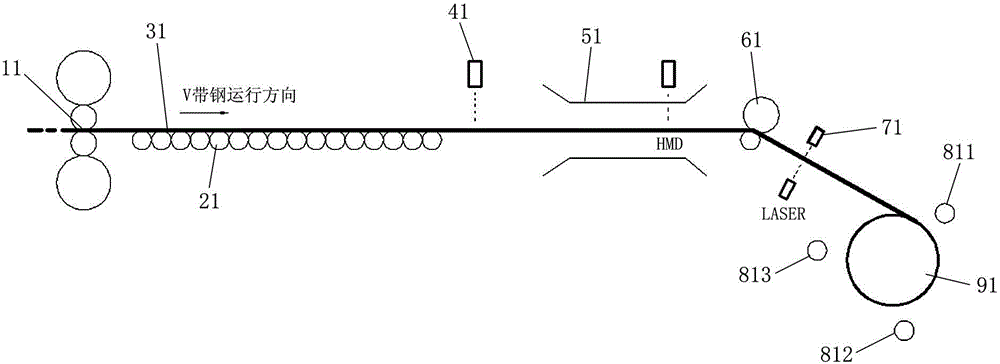

example 1

[0050] The specification of the free titanium plate is: thickness×width=10mm×1250mm. The rolling speed of the final stand 12 of the finishing mill is 2.4M / s.

[0051] parameter settings

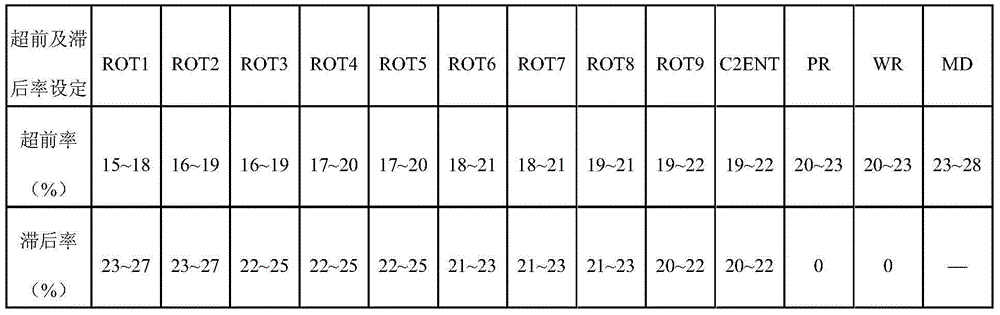

[0052] Before the titanium strip is coiled, the parameters are set first: the lead rates of ROT1~ROT9 are 15%, 16%, 16%, 17%, 17%, 18%, 18%, 19%, 19%, and the pinch rollers are 62%. The advance rates of the help roll and reel 92 are 20%, 20%, and 23% respectively; the lag rates of ROT1~ROT9 are 23%, 23%, 22%, 22%, 22%, 21%, and 21% respectively. , 21%, 20%. Wherein, the operation control system calculates the leading running speed and the lagging running speed according to the leading rate and the lagging rate.

[0053] In the position control mode, three short-stroke actions of the side guide plates approaching each other: the first time, when the head of the free plate 32 enters the bell mouth of the side guide plate 52, the short-stroke action is 50 mm; the second time, when the free pl...

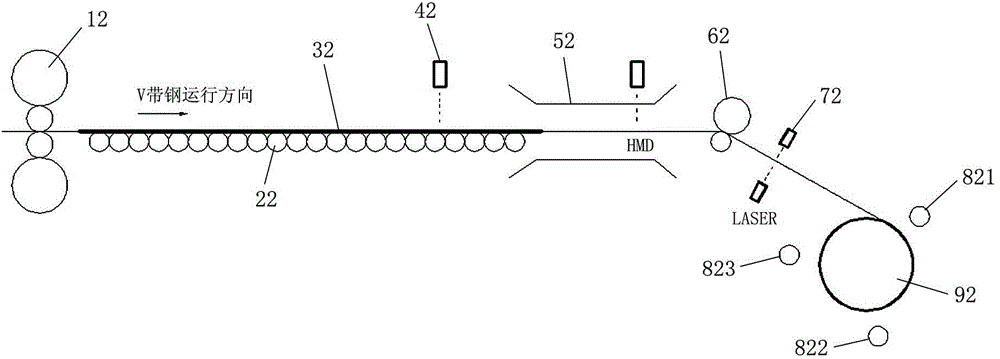

example 2

[0065] The specification of the free titanium plate is: thickness×width=12mm×1250mm. The rolling speed of the final stand 12 of the finishing mill is 2.2M / s.

[0066] parameter settings

[0067] Before the titanium strip is coiled, the parameters are set first: the lead rates of ROT1~ROT9 are 17%, 18%, 18%, 19%, 19%, 20%, 20%, 20%, 21%, and the pinch rollers are 62%. The lead rates of the help roll and reel 92 are 22%, 22%, and 26% respectively; the lag rates of ROT1~ROT9 are 25%, 25%, 23%, 23%, 23%, 21%, and 21% respectively. , 21%, 20%. Wherein, the operation control system calculates the leading running speed and the lagging running speed according to the leading rate and the lagging rate.

[0068] In position control mode, there are three short-stroke actions where the two sides of the side guide plate approach each other: the first time, when the head of the free plate 32 enters the bell mouth of the side guide plate 52, the short-stroke action is 50mm; When 32 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com