Mechanical tube cleaner speed controller

A technology of speed controller and pipe pig, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as strong time delay, prevent pipe burst accidents, and overcome excessive delay , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

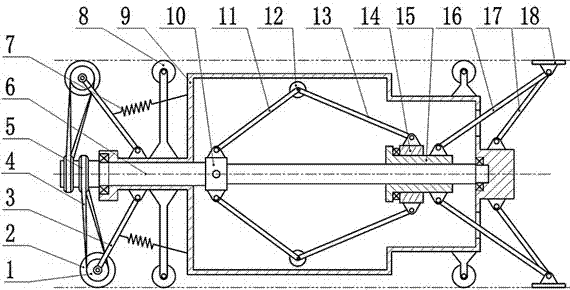

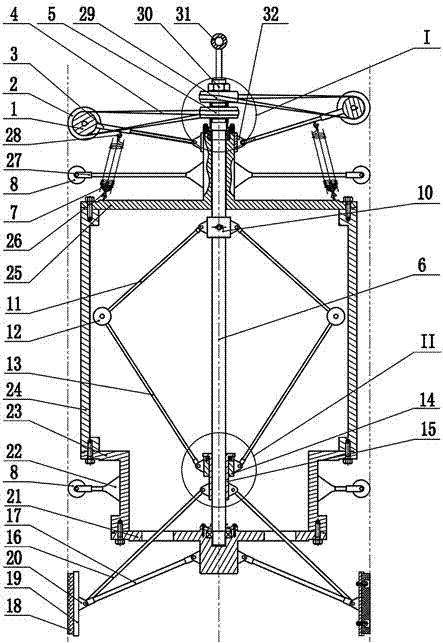

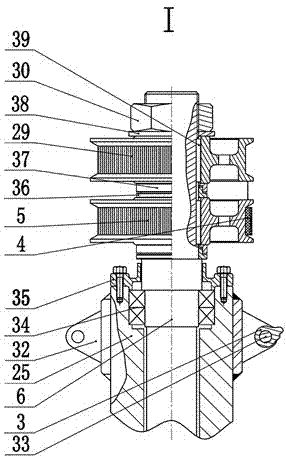

[0018] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 and figure 2 Partial enlarged view I ( image 3 ), partial enlarged view II ( Figure 4 ) the present invention is described as follows:

[0019] Such as figure 1 , 2 As shown, the cylinder body 9 is divided into a cylinder front end 25, a cylinder middle section 24, a cylinder tail section 23, and a cylinder end 21. The contact surfaces of each part are correspondingly processed with grooves and convex edges, which is convenient for installation and alignment. Bolt holes are machined at each joint and fastened with bolts. This design can facilitate the installation of the internal parts of the cylinder. After installing the mass block 12, the sleeve 10, the rotating cylinder 14, the fixed cylinder 15, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com