Heat cooling apparatus assembly of LED illuminating device having heat pipe and heat sink

A technology for LED lighting and cooling devices, applied in entertainment and other directions, can solve the problems of unsuitable LED lighting fixtures, the size or weight of cooling devices, etc., to maximize heat dissipation efficiency, improve heat dissipation effect, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following describes in detail with reference to the accompanying drawings of the present invention.

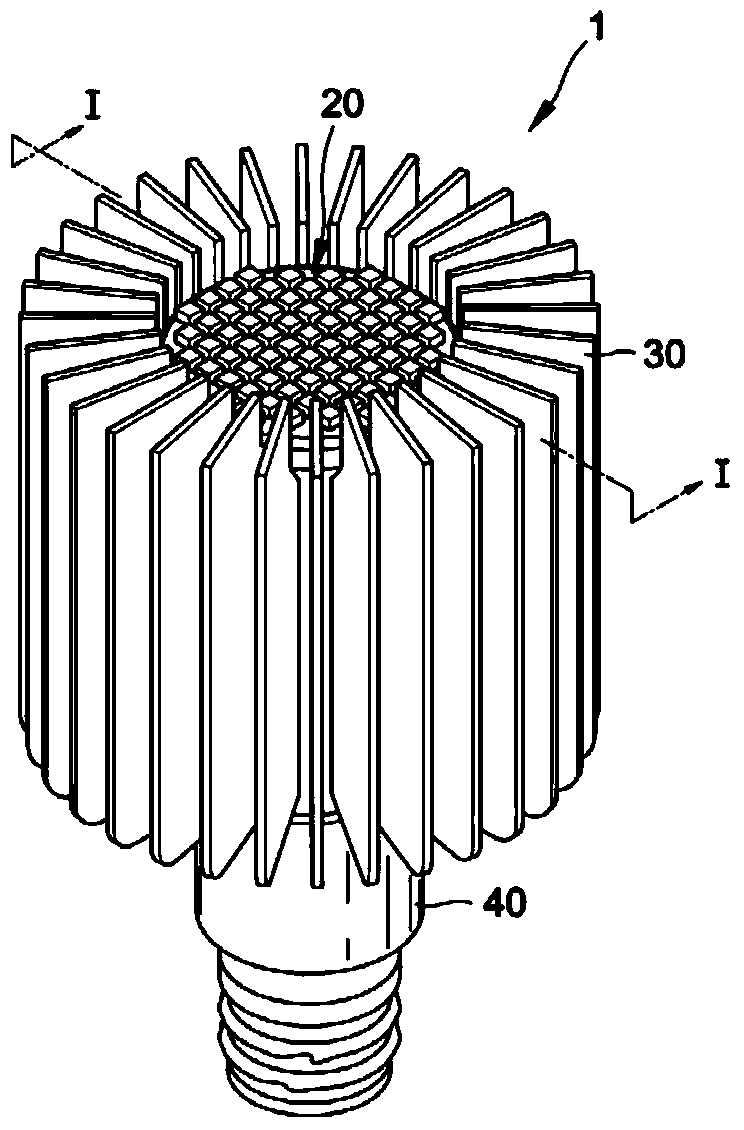

[0044] Figure 6 It is a figure which specifically illustrates the heat conduction pipe of this invention, Figure 7 and Figure 8 According to a preferred embodiment of the present invention, it is a diagram illustrating a state in which a heat pipe (400) of a cooling device for LED lighting fixtures is connected vertically rearward to an attachment plate (300) of the LED lighting fixtures.

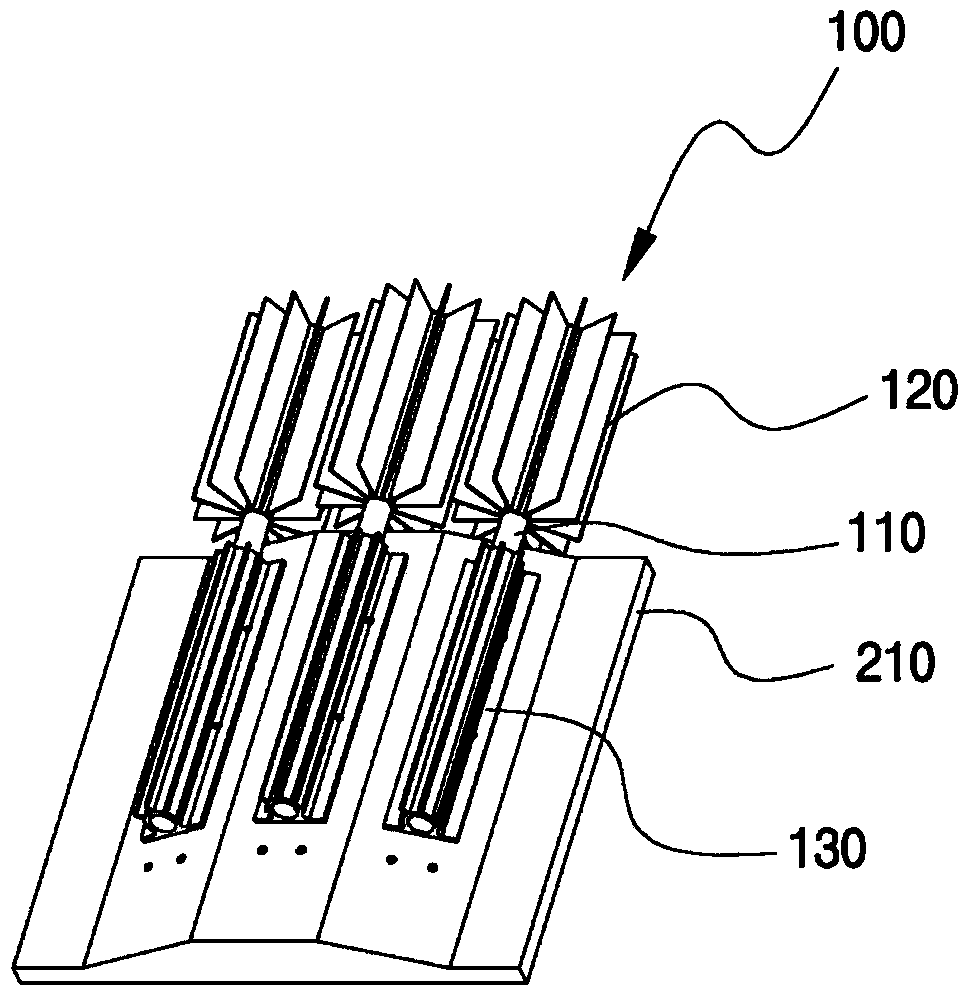

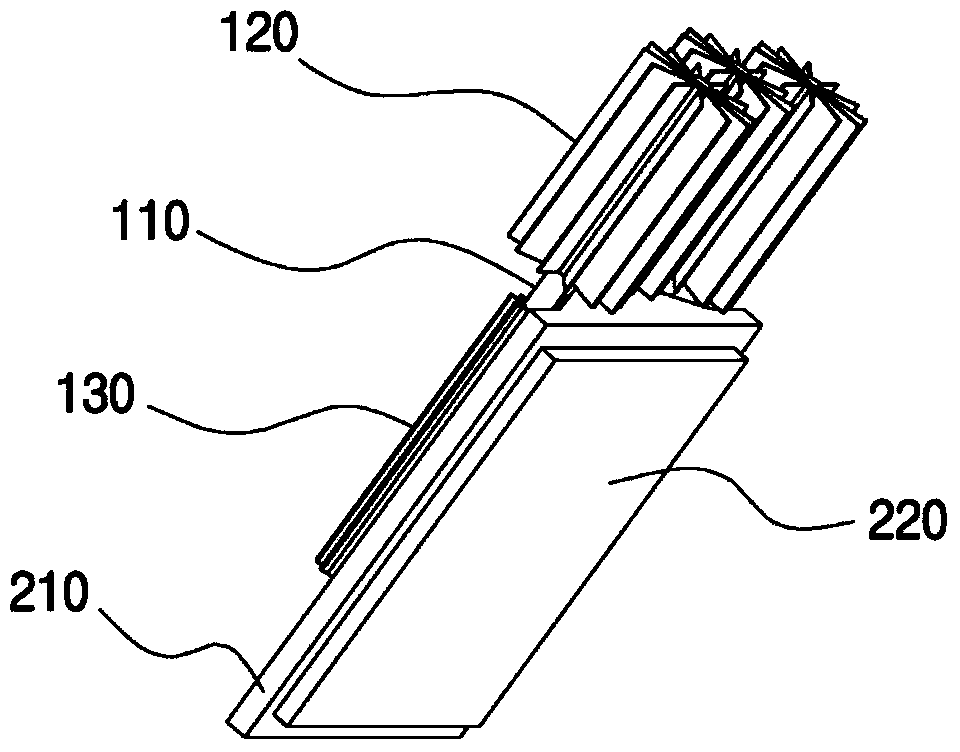

[0045] Such as Figure 5 As shown, the main components of the cooling device for LED lighting fixtures of the present invention are composed of a disc-shaped lighting fixture installation plate (300), a heat pipe (400) and a radiator (500), wherein the heat pipe (400 ) is fixed on the side opposite to the surface on which the lighting fixture is fixed on the mounting plate, and the heat sink (500) is mechanically press-attached and fixed on the outside of the heat pipe (400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com