Test block for carrying out ultrasonic inspection on residual stress of aluminium alloy pre-stretching board by water immersion

A pre-stretching plate and residual stress technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc., which can solve the problems of complex equipment, complex calibration procedures and dependencies. , to achieve the effect of large measurement depth, good economy and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

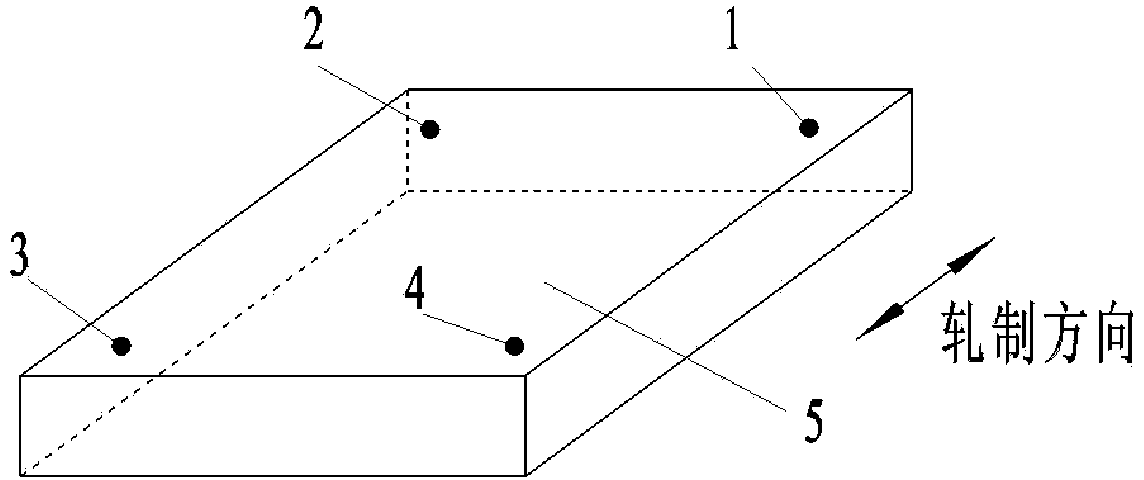

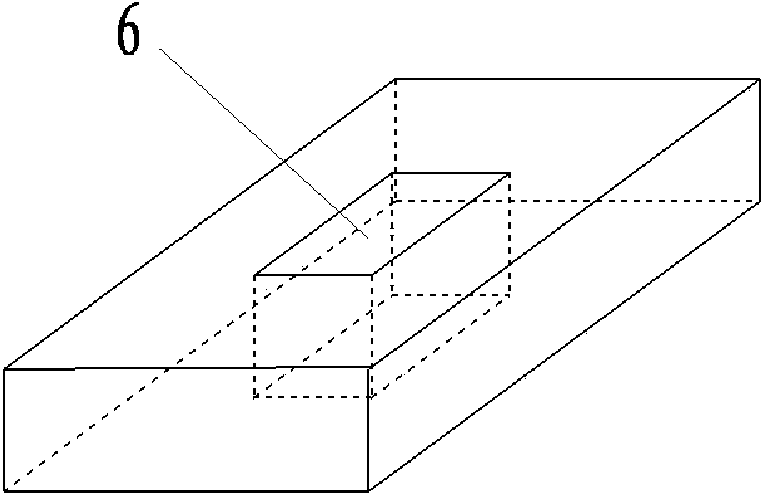

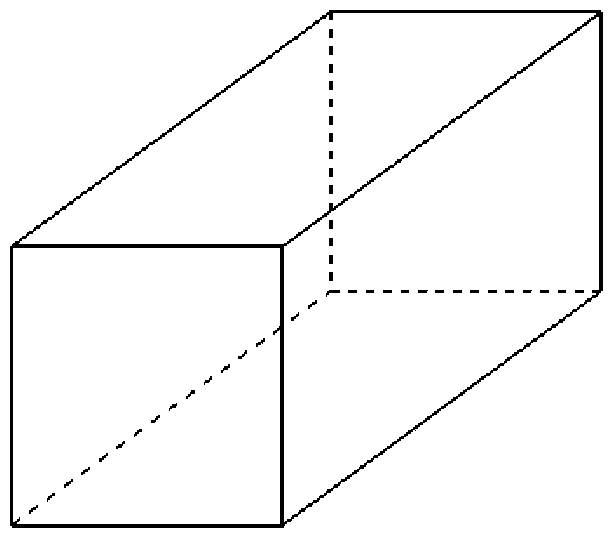

[0027] The aluminum alloy pre-stretched plate of the brand 7050-T7451 has a longitudinal wave sound velocity of 3200m / s, a length of 500mm, a width of 450mm, and a thickness of 160mm. It is required to detect the residual stress within 2mm near the surface. The detection steps are as follows:

[0028] ⑴Make reference test block

[0029] 1.1 Cut the sample

[0030] Cut a length of 100mm on the product of the same batch of pre-stretched plate 13 to be tested, a rectangular sample with a width of 90mm and a thickness of 20mm, one of the largest surfaces of the rectangular sample is the rolling surface of the pre-stretched plate, the largest surface Call the sample rolling surface 5, the length of the rectangular sample is the same as the rolling direction of the pre-stretched plate, use the drilling method to measure the residual stress of the sample rolling surface 1, the number of measuring points is four, and its position 10mm away from the long side and 15mm away from the w...

Embodiment 2

[0050] The aluminum alloy pre-stretched plate of the brand 7050-T7451 has a longitudinal wave sound velocity of 3200m / s, a length of 600mm, a width of 400mm, and a thickness of 140mm. It is required to detect the residual stress within 4mm near the surface. The detection steps are as follows:

[0051] ⑴Make reference test block

[0052] 1.1 Cut the sample

[0053] Cut a length of 100mm on the product of the same batch of pre-stretched plate 13 to be tested, a rectangular sample with a width of 90mm and a thickness of 20mm, one of the largest surfaces of the rectangular sample is the rolling surface of the pre-stretched plate, the largest surface Call the sample rolling surface 5, the length of the rectangular sample is the same as the rolling direction of the pre-stretched plate, use the drilling method to measure the residual stress of the sample rolling surface 1, the number of measuring points is four, and its position 10mm away from the long side and 15mm away from the w...

Embodiment 3

[0073] The aluminum alloy pre-stretched plate of the brand 7050-T7451 has a longitudinal wave sound velocity of 3200m / s, a length of 600mm, a width of 500mm, and a thickness of 80mm. It is required to detect the residual stress within 8mm near the surface. The detection steps are as follows:

[0074] ⑴Make reference test block

[0075] 1.1 Cut the sample

[0076] Cut a length of 100mm on the product of the same batch of pre-stretched plate 13 to be tested, a rectangular sample with a width of 90mm and a thickness of 20mm, one of the largest surfaces of the rectangular sample is the rolling surface of the pre-stretched plate, the largest surface Call the sample rolling surface 5, the length of the rectangular sample is the same as the rolling direction of the pre-stretched plate, use the drilling method to measure the residual stress of the sample rolling surface 1, the number of measuring points is four, and its position 10mm away from the long side and 15mm away from the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com