Manufacturing method for zigzag shafting alignment tool

A production method and bending shaft technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of inability to measure the offset and twist of the object, the value cannot be monitored and controlled, and the measured value is inaccurate. , to achieve intuitive measurement results, simple construction, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

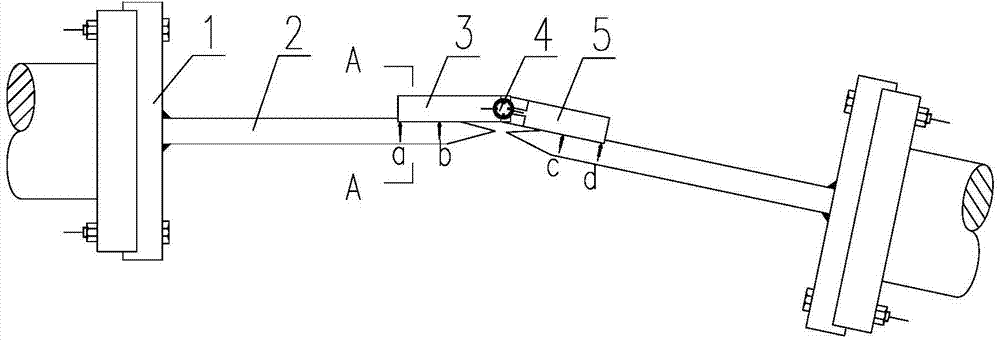

[0034] see figure 1 As shown, the embodiment of the present invention provides a method for manufacturing a zigzag shaft alignment tool, which includes the following steps:

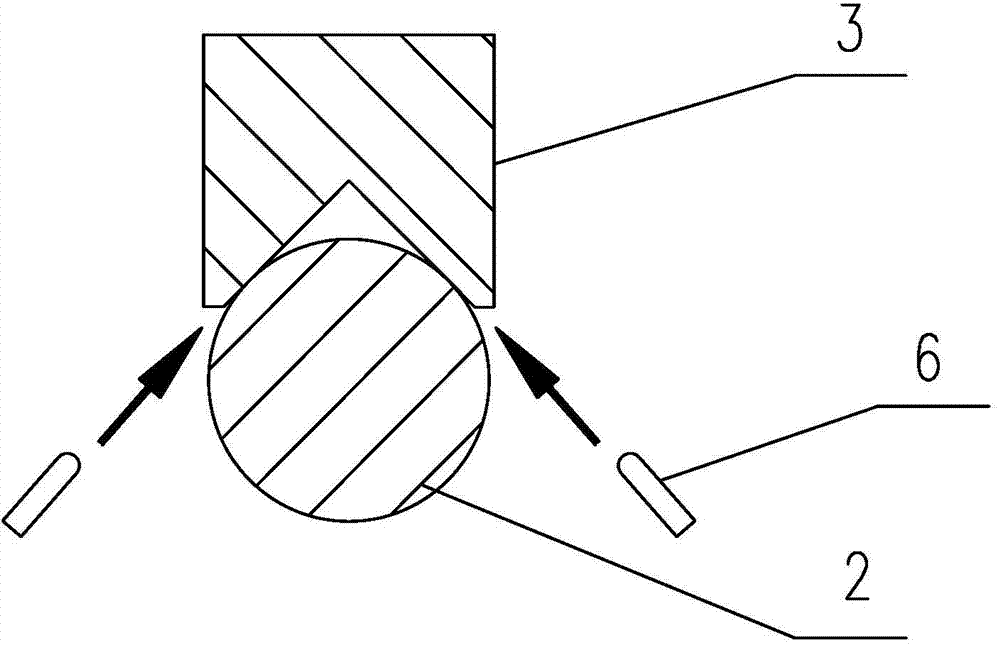

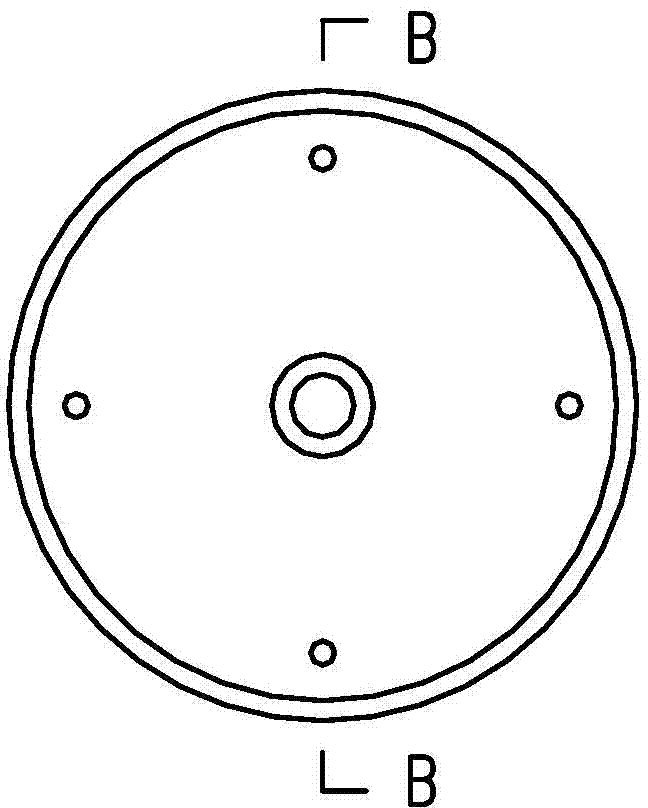

[0035] According to the number of zigzag inflection points designed on the zigzag shaft system, make a pair of calibration pointers between the adjacent input shafts and output shafts with a certain angle, see image 3 , Figure 4 As shown, each calibration pointer is a mechanical component welded by a flange 1 and a straight steel rod 2 with a tapered needle point. The straight steel rod 2 is concentric with the outer circle of the axially outer surface of the flange 1, and the two end faces of the flange 1 should be perpendicular to the axially outer surface of the straight steel rod 2. The outer diameter of the flange 1 and the graduation of the connecting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com