Inner contour measuring meter

A technology for measuring tables and inner contours, applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of high detection cost, low detection efficiency, and high detection condition requirements, and achieve the effect of low cost of use, high detection efficiency, and intuitive measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

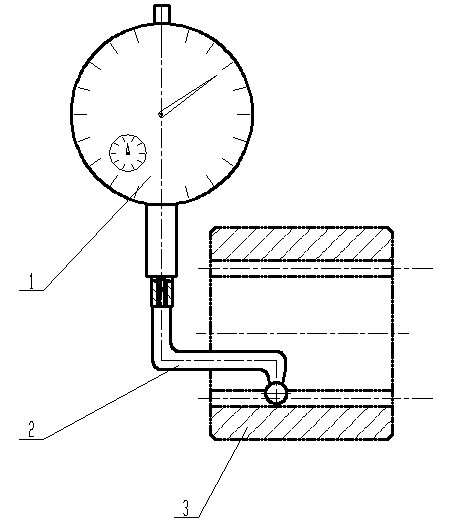

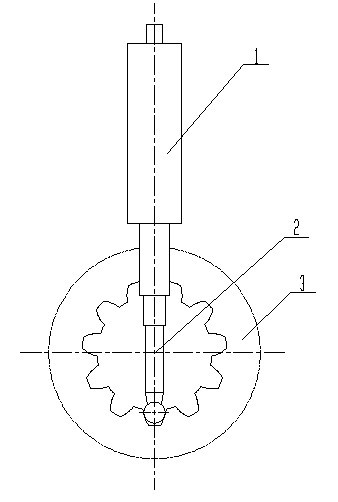

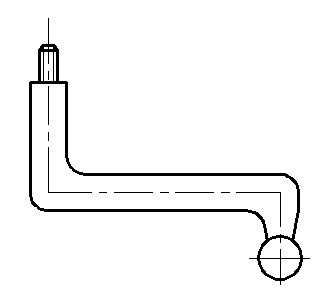

[0016] figure 1 The shown inner contour measuring instrument is composed of dial indicator 1 and measuring head 2. The dial indicator 1 is a commercial instrument supplied on the market. The original measuring head of the dial indicator 1 is removed, and an axial internal thread hole is left on the end face of the measuring rod. The probe 2 is as image 3 or Figure 4 The shown two-way right-angle bent rod shape, the external thread at the upward end is connected with the axial internal thread on the end face of the measuring rod of the dial indicator 1, and the downward end is the measuring end. In this embodiment, the workpiece 3 is as figure 1 or figure 2 The internal gear shown, choose image 3 As shown in the probe 2, the head of the probe 2 facing downward is spherical, and the probe 2 can be in contact with both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com