Coating composition capable of regulating surface friction coefficient of inner liner for cigarettes

A technology of inner lining paper and surface friction for cigarettes, applied in paper coating, coating, papermaking, etc., can solve problems affecting scratch resistance and smoothness, low friction coefficient, slipping, etc., and increase scratch resistance , Overcome shrinkage cavity and prevent slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a scheme for adjusting the coefficient of friction of the water-based varnish coating on the surface of the inner lining paper for cigarettes, which comprises the following steps:

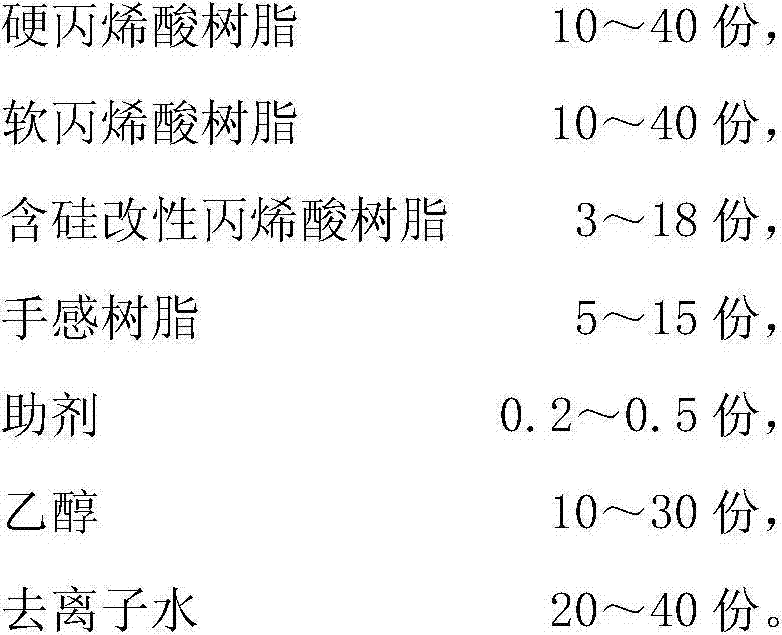

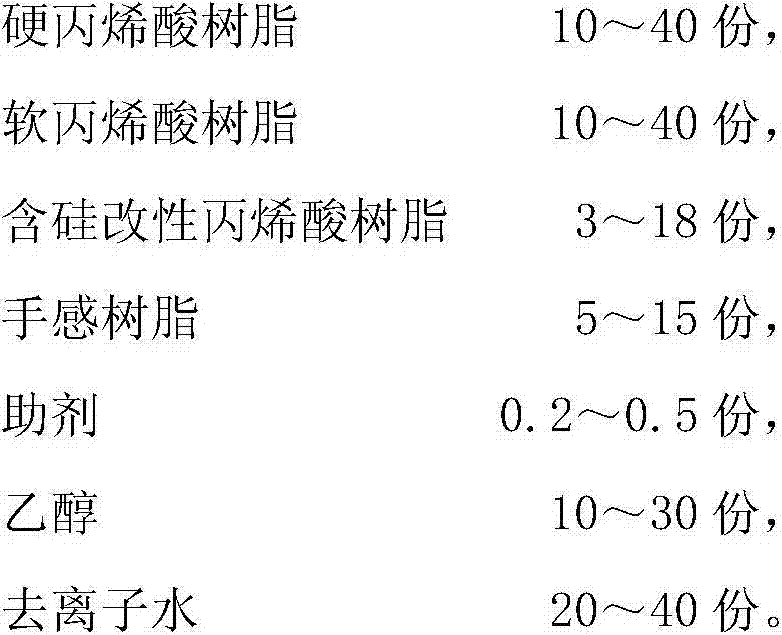

[0029] (1) Prepare materials according to the following components and content (parts by weight):

[0030] components

parts by weight

Hard acrylic resin SG-515

40

Soft acrylic resin AC-2782

10

Feel resin

15

Silicone modified acrylic resin

3

Leveling agent Levaslip W-409

0.25

10

[0031] Deionized water

35

[0032] (2) Mix the hard acrylic resin and 10 parts of deionized water, raise the temperature to 60° C., and stir at a low speed of 400 rpm for 8 minutes to obtain an aqueous solution of acrylate.

[0033] (3) Add hand-feeling resin while stirring, and stir at a low speed of 400 rpm for 8 minutes.

[0034] (4) Mix the ethanol and the remaining deio...

Embodiment 2

[0037] This embodiment relates to a scheme for adjusting the coefficient of friction of the water-based varnish coating on the surface of the inner lining paper for cigarettes, which comprises the following steps:

[0038] (1) Prepare materials according to the following components and content (parts by weight):

[0039] components

parts by weight

Hard acrylic resin SG-515

30

Soft acrylic resin AC-2782

20

Feel resin

12

Silicone modified acrylic resin

7

Wetting agent Tego Wet260

0.5

ethanol

10

Deionized water

40

[0040] (2) Mix the hard acrylic resin, the soft acrylic resin and 4 parts of deionized water, raise the temperature to 60° C., and stir at a low speed of 300 rpm for 10 minutes to obtain an aqueous acrylate solution.

[0041] (3) While stirring, add silicon-modified acrylic resin and hand resin, and stir at a low speed of 300 rpm for 10 minutes.

[0042] (4) Mix the etha...

Embodiment 3

[0045] This embodiment relates to a scheme for adjusting the coefficient of friction of the water-based varnish coating on the surface of the inner lining paper for cigarettes, which comprises the following steps:

[0046] (1) Prepare materials according to the following components and content (parts by weight):

[0047] components

parts by weight

Hard acrylic resin SG-515

20

Soft acrylic resin AC-2782

30

Feel resin

10

Silicone modified acrylic resin

10

Leveling agent Levaslip W-409 and wetting agent Tego Wet260 with a mass ratio of 1:1

0.45

ethanol

20

Deionized water

20

[0048] (2) Mix the hard acrylic resin, the soft acrylic resin and 8 parts of deionized water, raise the temperature to 60°C, and stir at a low speed of 500 rpm for 5 minutes to obtain an aqueous acrylate solution.

[0049] (3) While stirring, add silicon-modified acrylic resin and hand resin, and stir at a low s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com