Rapid freezing method of polycrystalline silicon

A technology of polycrystalline silicon and directional solidification, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low yield and high proportion of ingots, and achieve the effect of easy breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

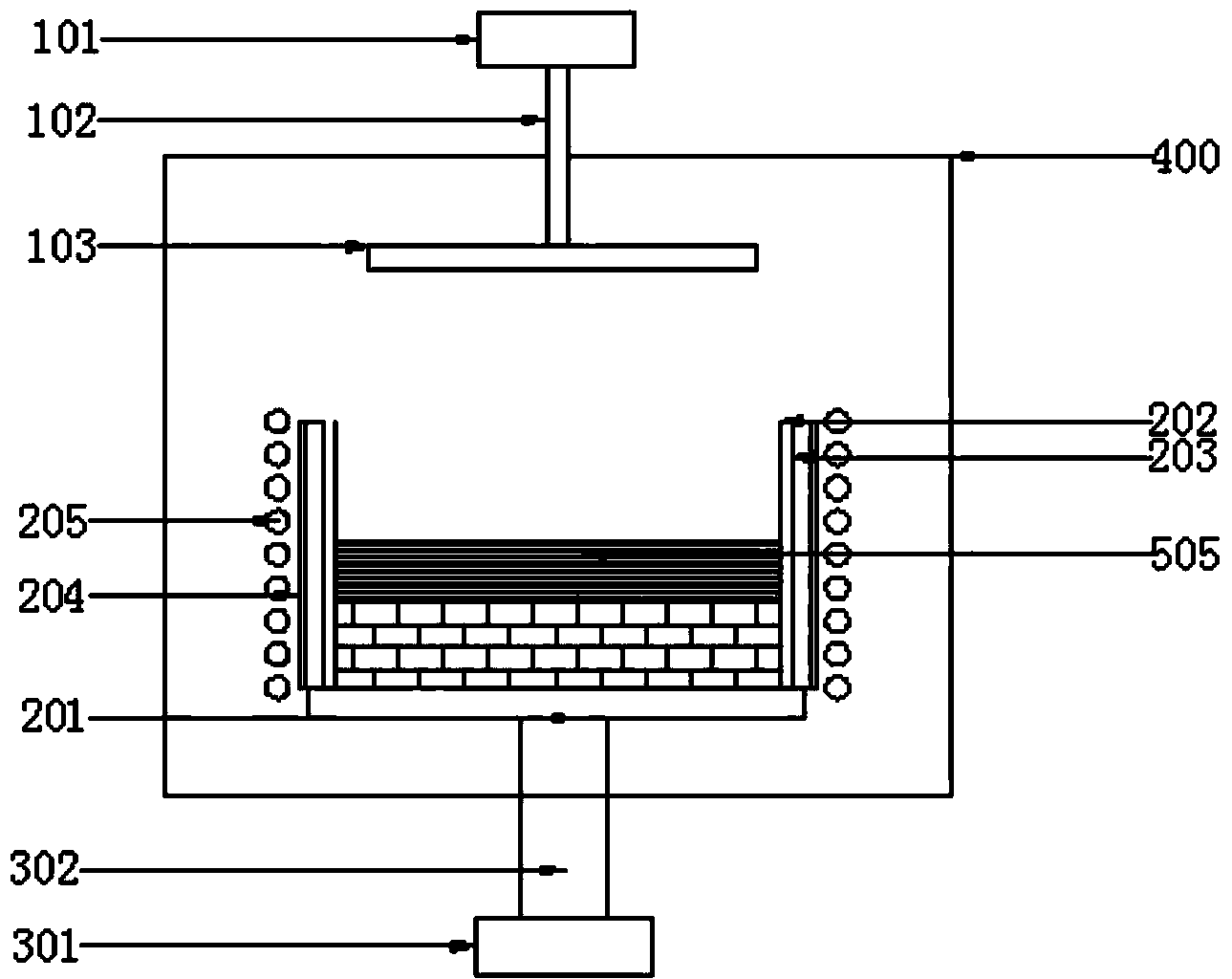

[0031] A polysilicon reverse solidification device includes a furnace body 400, a vacuum system, an air filling system, a directional solidification smelting system, a top lifting mechanism, a bottom lifting mechanism, pipes for connection, and valves arranged on the furnace body and each pipe.

[0032] The vacuum system includes a mechanical pump and a Roots pump, a vacuum pipeline communicated with the furnace body and a vacuum gauge.

[0033] The inflation system includes an argon gas tank, an inflation pipeline, a pressure gauge and a flow meter.

[0034] The top lifting mechanism includes a top lifting and rotating device 101, the lower end of the top lifting and rotating device 101 is fixed with a water-cooled metal rod 102, and the other end of the water-cooled metal rod 102 is fixed with a water-cooled copper plate 103; the top lifting and rotating device 101 is located outside the furnace body 400 , the water-cooled metal rod 102 passes through the upper surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com