Preparation method of LiMgN-containing high-capacity hydrogen storage material

A hydrogen storage material and high-capacity technology, which is applied in the field of preparation of high-capacity hydrogen storage materials, can solve the problems of unobtainable products and low LiMgN phase content, and achieve the effects of regular material morphology, simple preparation process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

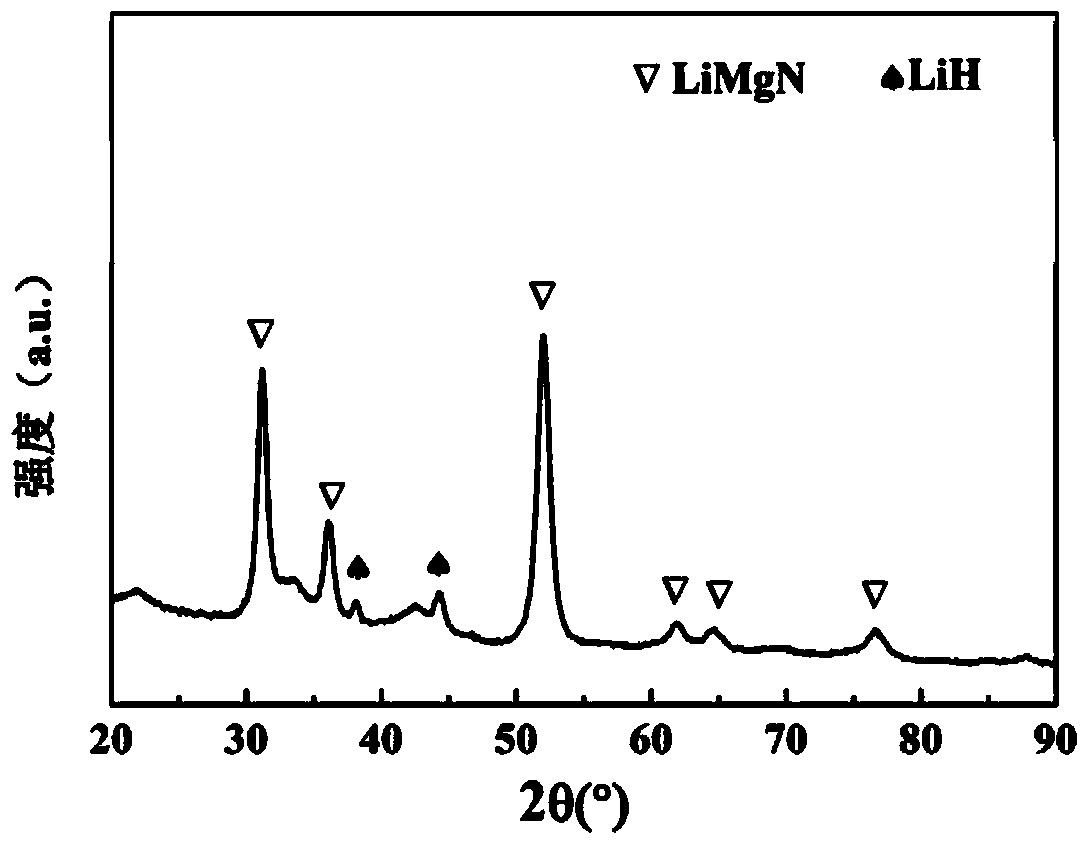

[0030] The raw material is commercially available lithium nitride powder (Li 3 N, purity 99.4%) and magnesium hydride powder (MgH 2 , purity 98%), the two are uniformly mixed at a molar ratio of 1:1, take 3g of the mixed raw material, put it into a 250ml ball mill jar, the ratio of the grinding ball to the mixed raw material is 40:1, and fill it with 2bar argon (Ar) for Protection, ball milling speed 500rpm, ball milling time 12h, and rest 5min every 10min during ball milling, in order to prevent ball milling tank from overheating during ball milling. Sample MgH 2 Decomposition occurs. The products after ball milling are LiMgN (main phase) and LiH.

[0031] figure 1 Lithium nitride (Li 3 N) and magnesium hydride (MgH 2 ) Scanning electron micrograph of the product after ball milling. It can be seen from the above pictures that the obtained materials are agglomerated together, and the particle size after agglomeration is about 100-200 nanometers.

[0032] figure 2 Lith...

Embodiment 2

[0037] Lithium nitride powder (Li 3 N, purity 99.4%) and magnesium hydride powder (MgH 2, purity 98%) uniformly mixed at a molar ratio of 1:2, take 3g of mixed raw materials, put them into a 250ml ball mill jar, the ratio of grinding balls to mixed raw materials is 40:1, fill with 2bar argon (Ar) for protection, and ball mill The rotating speed is 500rpm, the ball milling time is 12h, and there is a 5min rest every 10min of ball milling during the ball milling process. The product after ball milling is Mg 3 N 2 (main phase), LiH phase and MgH 2 Mutually.

[0038] Figure 6 Lithium nitride (Li 3 N) and magnesium hydride (MgH 2 ) XRD detection pattern after mixing ball milling at a molar ratio of 1:2. From the detection pattern in XRD, it can be found that the main phase after ball milling is Mg 3 N 2 , LiH and MgH 2 . Description In Lithium Nitride (Li 3 N) and magnesium hydride (MgH 2 ) can not prepare products with LiMgN as the main phase under the mixing ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com