NiF2-dopped LiBH4-LiNH2-CaH2 composite hydrogen storage material and preparation method thereof

A hydrogen storage material, awt%libh4-bwt%linh2-cwt�h2-dwt%nif2 technology, applied in the production of hydrogen and other directions, can solve the problem of high hydrogen desorption temperature, and achieve the effect of accelerating the performance of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: NiF 2 Doped LiBH 4 -LiNH 2 -CaH 2 Preparation of Composite Hydrogen Storage Materials

[0026] In the glove box under the protection of argon, take by weight 0.5g LiBH altogether by mass ratio 15wt%: 50wt%: 30wt%: 5wt% 4 、LiNH 2 , CaH 2 and NiF 2 The raw materials were poured into a 100mL ball mill jar with five 10mm stainless steel balls (17.5g), sealed and taken out from the glove box; the ball mill jar was loaded on the planetary ball mill QM-3SP2; the milling speed was set to 200r / min, the ball milling time is 15h, after the ball milling is completed, put the ball mill jar back into the glove box for sampling.

[0027] Prepare different composite hydrogen storage materials by changing the additive and the doping amount of the additive; the raw material is LiBH 4 、LiNH 2 , CaH 2 and NiF 2 ;The additive is NiF 2 .

Embodiment 2

[0028] Embodiment 2: the NiF that embodiment 1 prepares 2 Doped LiBH 4 -LiNH 2 -CaH 2 TG-MS Analysis of Composite Hydrogen Storage Materials

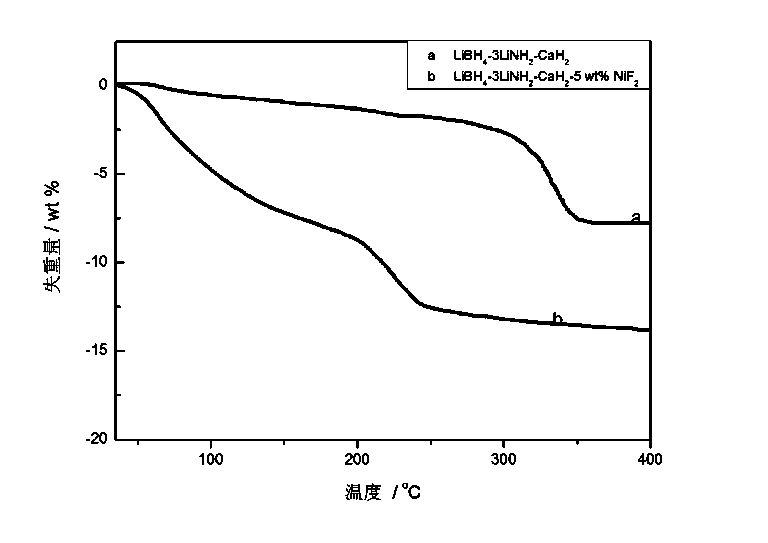

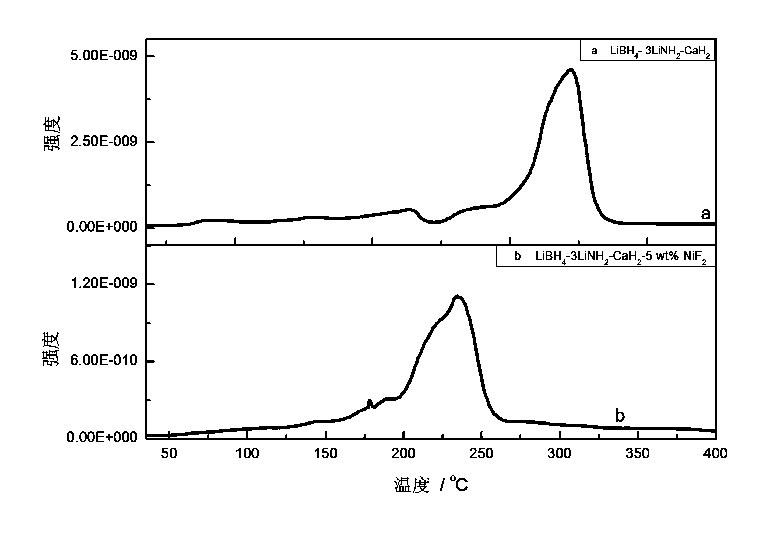

[0029] A 90 mg sample was weighed from the glove box for thermogravimetric-mass spectrometry (TG-MS) analysis. The test used TherMax 500 high-pressure thermobalance and GAM 200 mass spectrometer, the Ar gas flow rate was controlled at 1.7% (-145mL / min), and the system was vacuumed (5-10min) for ventilation after loading the sample. It is RT-400°C, and the heating rate is 5°C / min. The analysis results showed that the LiBH without catalyst 4 -LiNH 2 -CaH 2 The sample released hydrogen slowly before 300°C, and the weight loss only reached about 2.7wt%. Add NiF 2 The sample has completed a large amount of hydrogen desorption at about 250°C, with a total weight loss of more than 13wt%, such as figure 1 shown, indicating NiF 2 to LiBH 4 -LiNH 2 -CaH 2 The composite system has obvious catalytic effect, which can accelerate the de...

Embodiment 3

[0030] Embodiment 3: the NiF that embodiment 1 prepares 2 Doped LiBH 4 -LiNH 2 -CaH 2 DSC Analysis of Composite Hydrogen Storage Materials

[0031] The test used the Q1000DSC produced by TA Company in the United States, and the flow rate of the Ar gas carrier was controlled at 50mL / min. To avoid oxidation of the material during loading into the crucible, this operation was performed in a glove box.

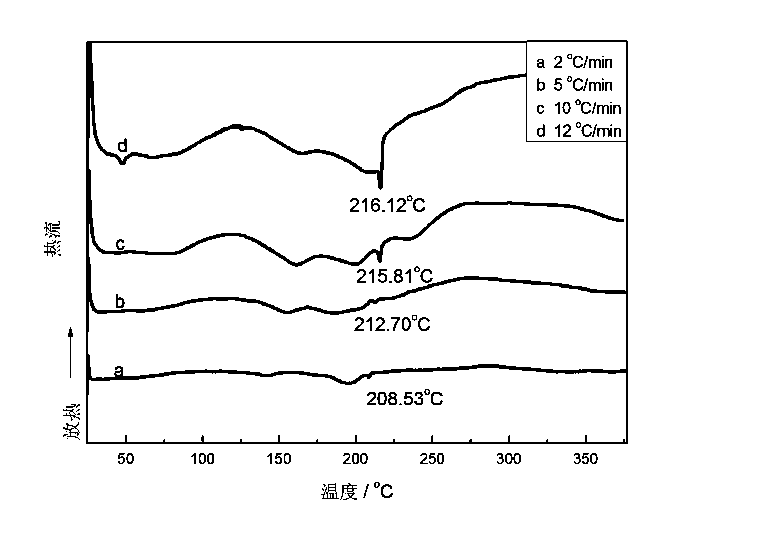

[0032] Figure 3A Doped with 5wt% NiF at different heating rates 2 The DSC curve of the composite system. The results show that: when the heating rate is changed (2°C / min, 5°C / min, 10°C / min, 12°C / min), the peak temperature of the system changes regularly, that is, with the increase of the heating rate , the melting point of the system increases gradually. At the same time, for LiBH prepared by ball milling under the same conditions 4 -LiNH 2 -CaH 2 The system was compared with the doped sample, such as Figure 3B shown. The results show that: doped with 5wt% NiF 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com