\Walnut protein powder and preparation method thereof

A technology of protein powder and walnut, which is applied in the direction of plant protein processing, etc., and can solve the problems of high oil content in walnut cake, intolerance to storage, limited application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

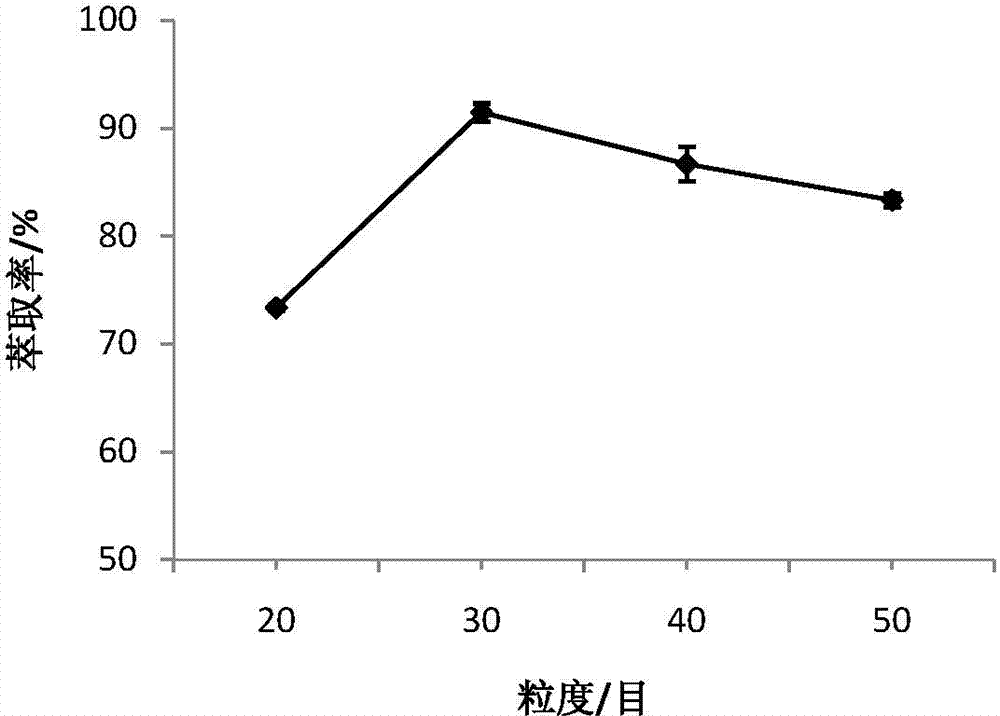

[0030] Embodiment 1, investigate the influence of the particle size of different coarsely pulverized walnut cakes on extraction rate

[0031] 1) Using walnut kernels as raw materials, use a twin-screw oil press to squeeze out most of the oil at a low temperature of 70 ° C, until the mass percentage of the oil is 8%, to obtain walnut cake;

[0032] 2) After pulverizing the walnut cakes obtained in step 1) to 20, 30, 40 and 50 meshes with a hammer mill, use supercritical CO 2 The extraction equipment was used for extraction, and the extraction conditions were as follows: extraction pressure 30MPa, extraction temperature 45°C, and extraction time 2 hours. The mass percentages of oils and fats in the products obtained after extraction were 2.13%, 0.68%, 1.06% and 1.33%, respectively.

[0033] 3) Put step 2) supercritical CO 2 The extracted product is ultrafinely pulverized to a particle size of 100 meshes, and the sieving rate of the product at 100 meshes is over 95%, thereby ob...

Embodiment 2

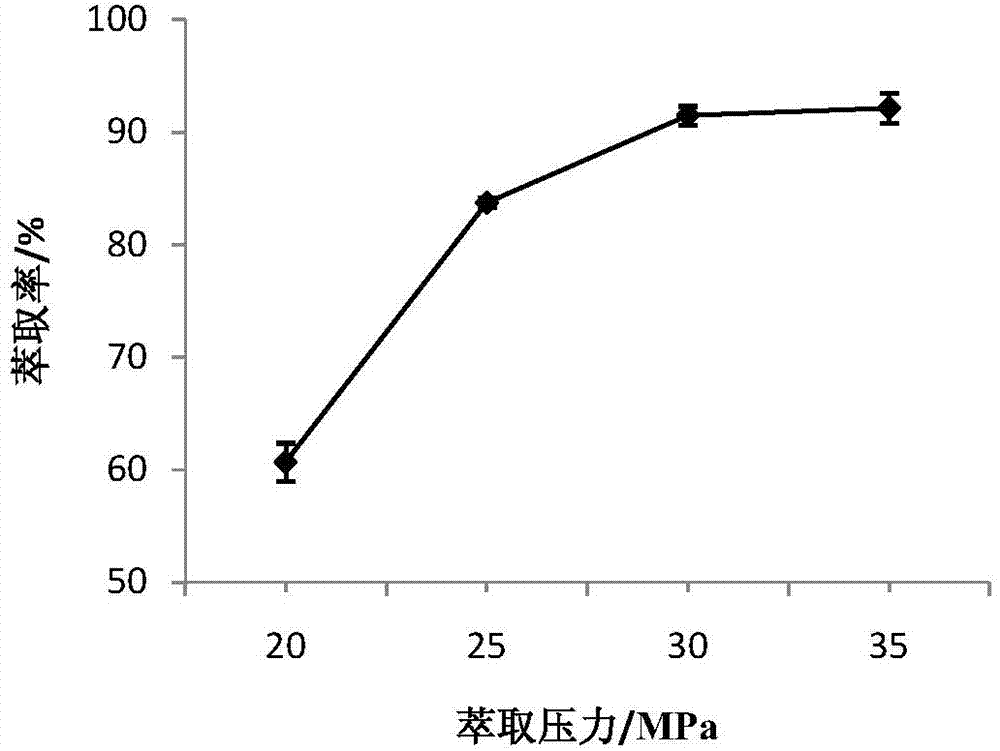

[0040] Embodiment 2, investigate the influence of different extraction pressure on extraction rate

[0041] According to the steps of Example 1, only the number of meshes pulverized with a hammer mill in step 2) was fixed at 30 meshes, and the extraction pressure was sequentially replaced by 20 MPa, 25 MPa, 30 MPa, and 35 MPa to obtain the walnut protein powder provided by the present invention. The mass percentages of oils and fats in the product were 3.15%, 1.3%, 0.68%, and 0.63%, respectively.

[0042] The results of the extraction rates corresponding to the walnut protein powder obtained by the above-mentioned different extraction pressures, see figure 2 .

[0043] Depend on figure 2 It can be seen that when the extraction rate is in the range of 20-30MPa, the extraction rate increases rapidly with the increase of extraction pressure. When the extraction pressure reaches 30MPa, the extraction rate tends to be flat. Considering the energy consumption factor, the extra...

Embodiment 3

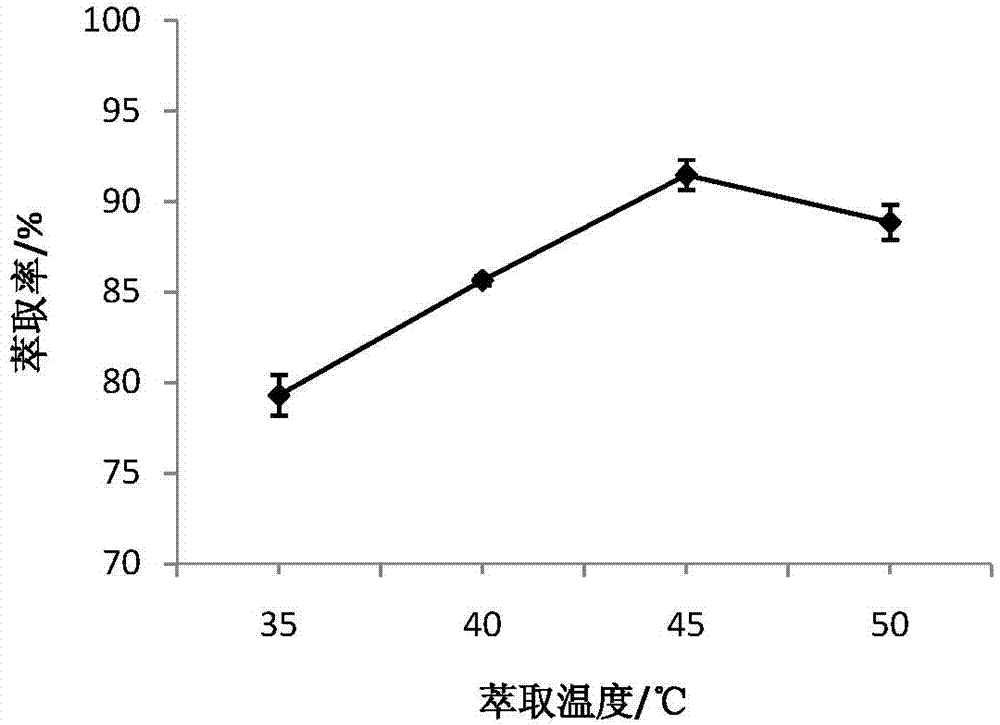

[0044] Embodiment 3, investigate the influence of different extraction temperatures on extraction rate

[0045] According to the steps of Example 1, only the number of meshes pulverized by the hammer mill in step 2) is fixed at 30 meshes, and the extraction temperature is sequentially replaced by 35°C, 40°C, 45°C, and 50°C to obtain the walnut protein provided by the present invention. pink. The mass percentages of oils and fats in the products were 1.66%, 1.15%, 0.68%, and 0.89%, respectively.

[0046] The results of the corresponding extraction rates of the walnut protein powder obtained from the above-mentioned different extraction temperatures, see image 3 .

[0047] Depend on image 3It can be seen that with the increase of the extraction temperature, the extraction rate first increases and then decreases. When the extraction temperature is 45 °C, the extraction rate is the largest, so the extraction temperature of 45 °C is selected as the supercritical CO 2 The opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com