Mutual inductance coupling type switch magnetic resistance motor

A technology of switched reluctance motor and mutual inductance coupling, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, the shape/style/structure of the winding conductor, etc. Problems such as large torque ripple and low material utilization rate can achieve the effect of increasing current utilization efficiency, small torque ripple, and less copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

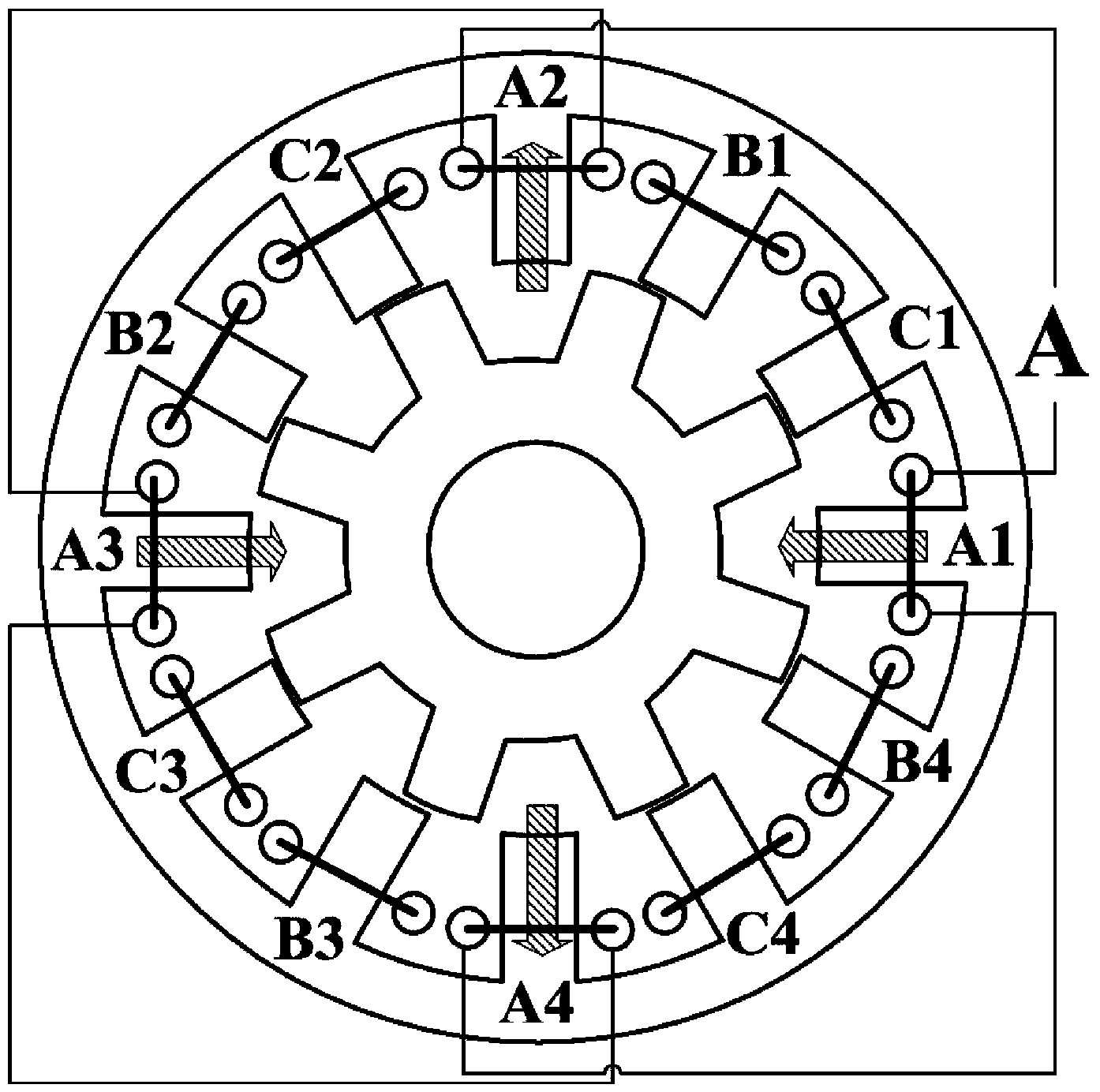

[0029] A mutual induction coupling switched reluctance motor of the present invention comprises a stator 1 , a mutual induction coupling concentrated winding 2 and a rotor 3 . The stator 1 is provided with an even number of stator teeth, and stator slots are formed between adjacent stator teeth, and each stator tooth is opposed to another stator tooth along the radial direction of the stator. The concentrated winding coil 2 is wound on the stator teeth, which is a double-layer winding structure, nested on all the salient pole teeth of the stator 1, and two coil edges belonging to different coils are placed in each stator slot, that is, all stator teeth There are coils nested, the number of coils is equal to the number of stator teeth, and each phase winding is composed of several coils connected in series or in parallel or in series and para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com