Full-automatic backlight plate assembly device

A backlight and fully automatic technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of reducing the market competitiveness of enterprises, high labor costs, low production efficiency, etc., to facilitate promotion, improve stability and Efficiency, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

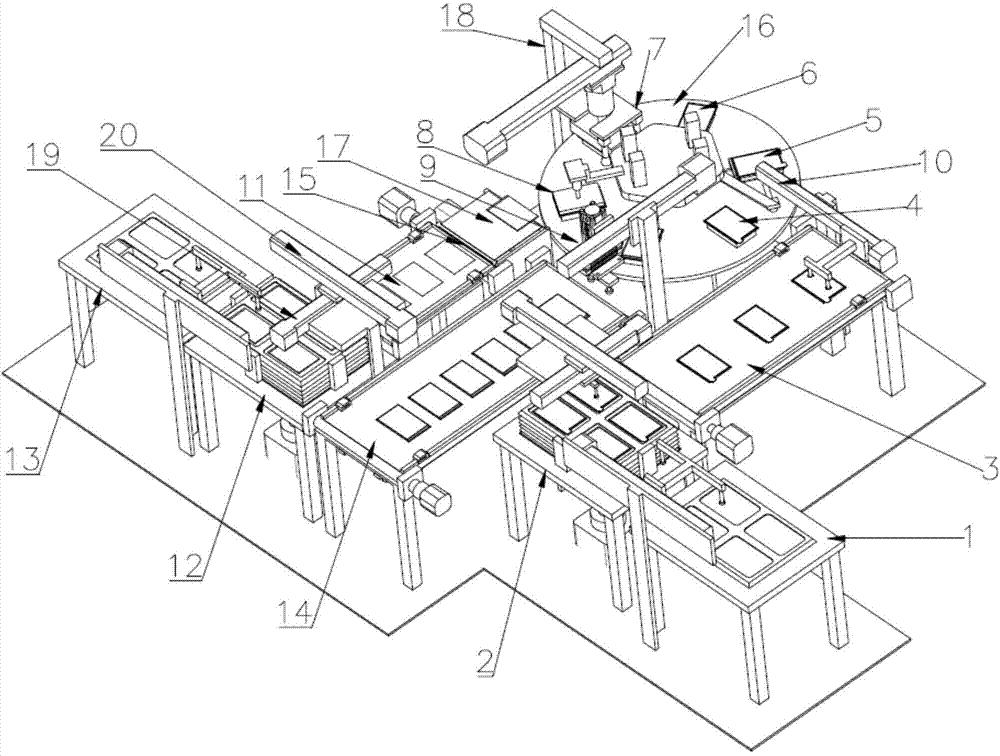

[0049] Such as figure 1 As shown, a fully automatic backlight panel assembly equipment includes a backlight panel feeding system, a liquid crystal panel feeding system, a bonding system, a finished product output system, and a handling device.

[0050] The specific composition structure is as follows:

[0051] The backlight feeding system includes a backlight feeding platform 1 , a backlight temporary storage platform 2 and a backlight conveying channel 3 arranged in sequence.

[0052] The liquid crystal panel feeding system includes a liquid crystal panel feeding platform 13 , a liquid crystal panel temporary storage platform 12 , a liquid crystal panel conveying channel 11 , a panel dust removal device 15 and a protective film stripping device 10 arranged in sequence. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com