Device and method for passive electrical detection of laser plasma

A laser plasma and detection device technology, applied in the field of material processing, can solve the problems of difficult positioning and adjustment, no plasma detection, limited detection range, etc., and achieves easy implementation, improved stability and reliability, and detection time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

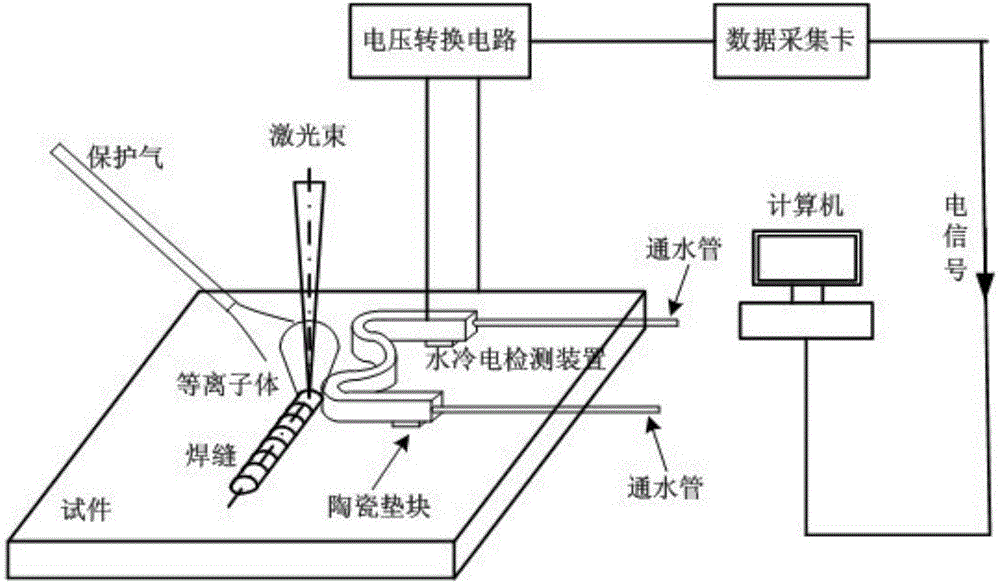

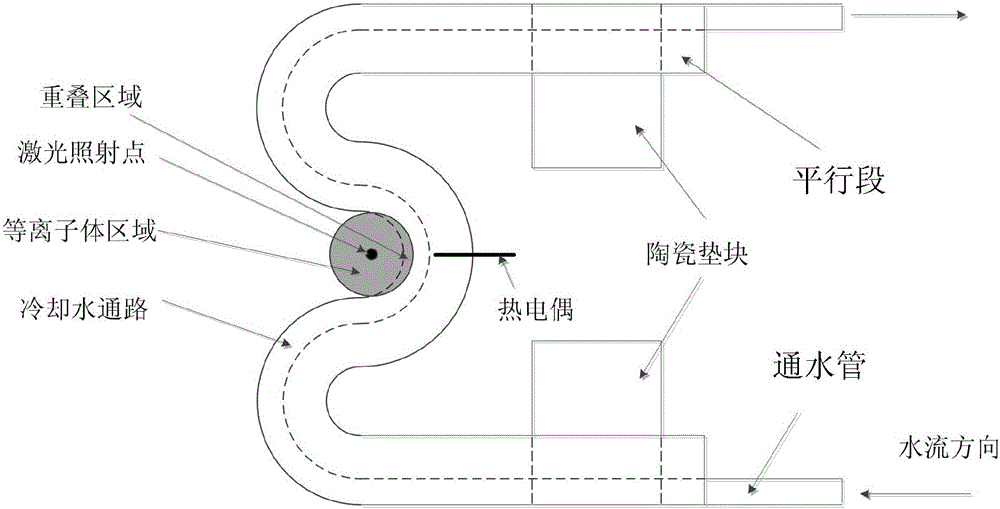

[0028] as attached figure 1 As shown in -2, the passive electric detection device for laser plasma is composed of two parallel segments parallel to each other and an arc segment connecting the parallel segments, the overall appearance is M-shaped, and the cross section of the electric detection device is rectangular, and A flow channel is arranged inside the electric detection device for the flow and circulation of water; a thermocouple is built in the center of the arc section, the position of the thermocouple is 1-2 mm away from the bottom of the electric detection device, and the depth of the embedded electric detection device is 3-2 mm. 5mm, the flow channel set inside should not affect each other with the thermocouple; the parallel sections at both ends are respectively connected to the water pipe; the electrical detection device is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com