Hydraulic fracturing control method of cut tight roof/top coal

A hydraulic fracturing and hard roof technology, which is applied in earth square drilling, surface mining, underground mining, etc., can solve problems such as potential safety hazards, large-area pressure on the roof, and gas exceeding the limit, so as to prevent sudden extrusion and reduce Air leakage, improve the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

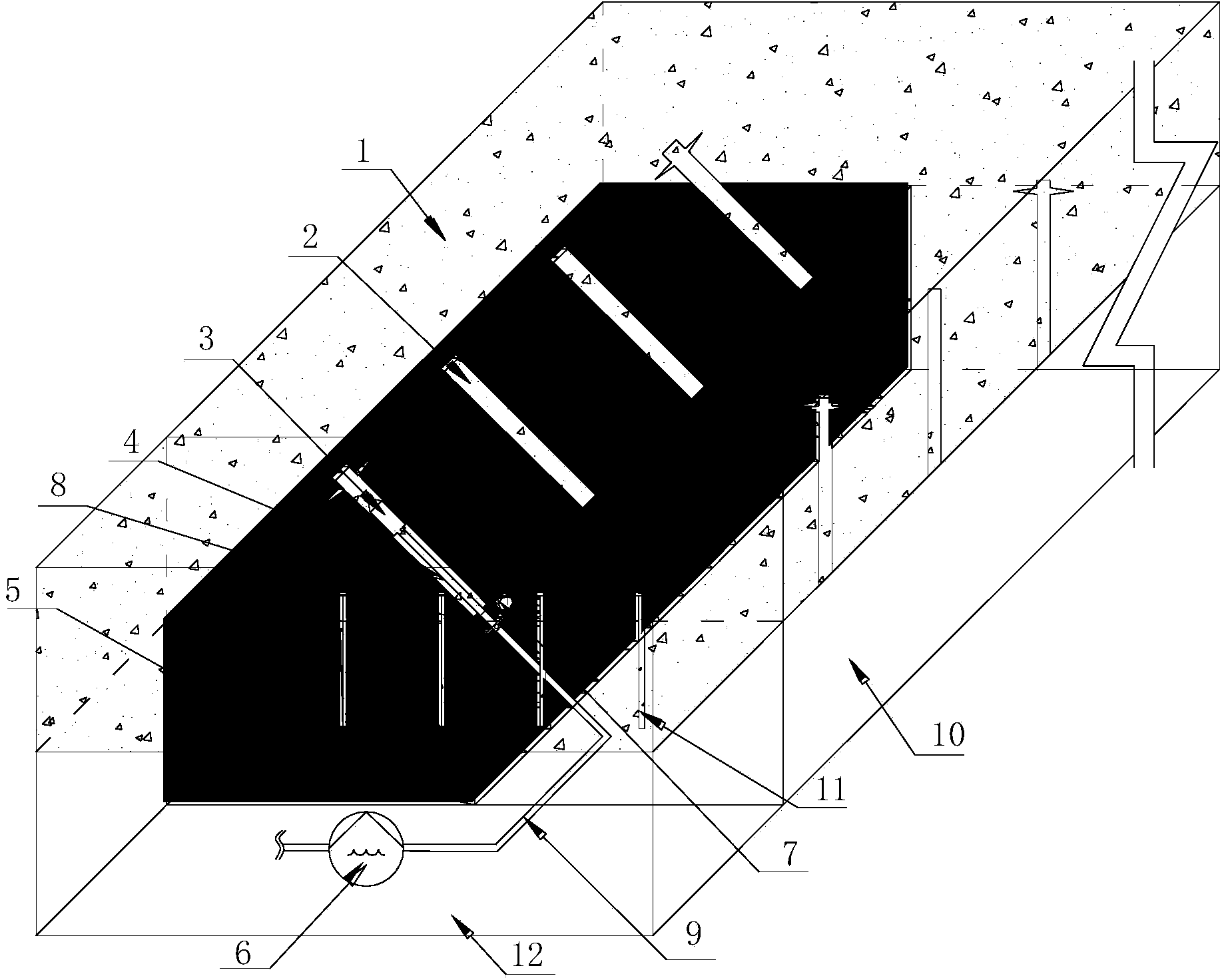

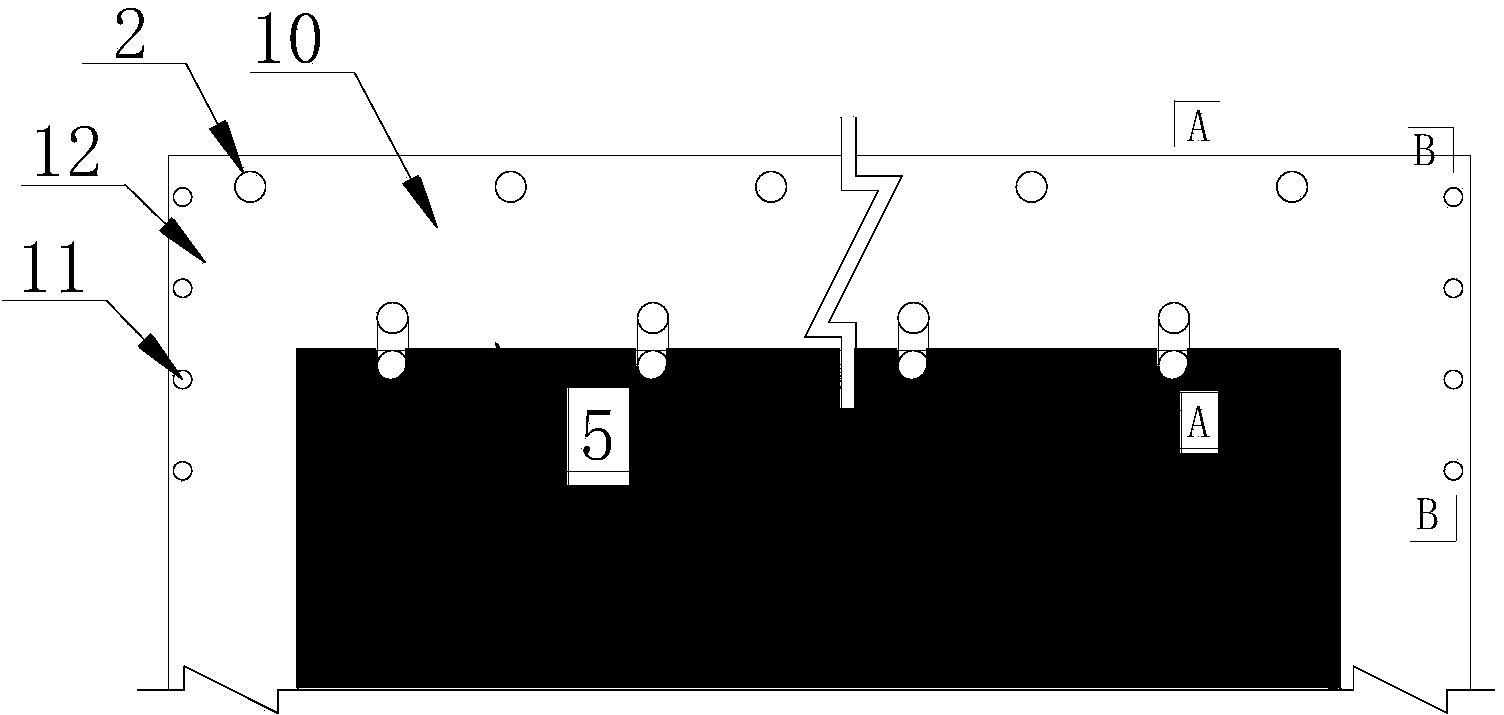

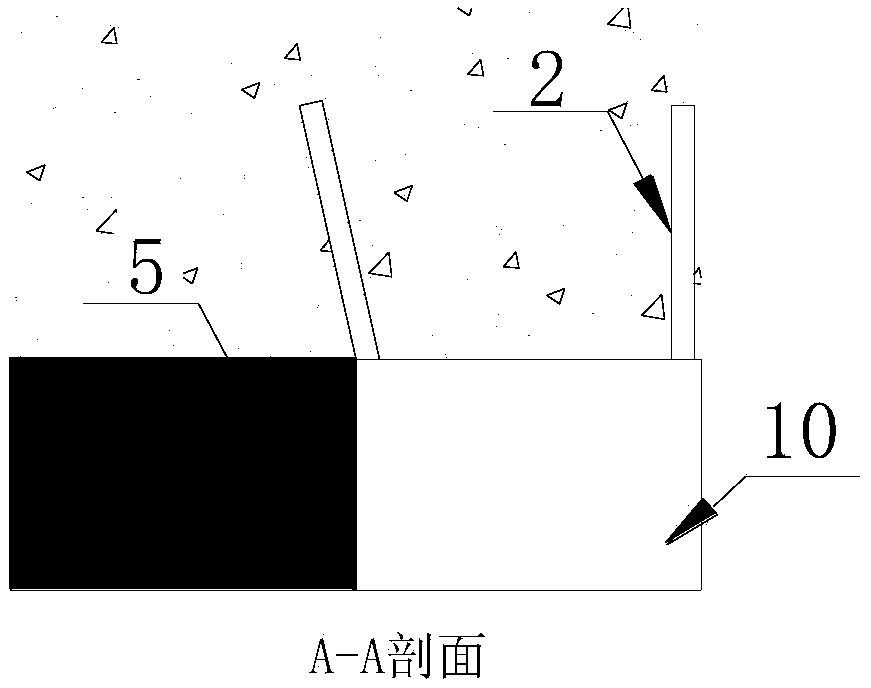

[0026] Embodiment one: if figure 1 , figure 2 As shown, the average thickness of the coal seam in a certain mine is 2.28m, the height of the cut hole is 2.8m, the length is 300m, the width is 7.8m, and the length of the anchor cable is 8m; the immediate roof is dark gray sandy mudstone with an average thickness of 13.27m; the old roof is gray siltstone, The average thickness is 21.8m, and the immediate bottom is dark gray sandy mudstone, with an average thickness of 1.42m; the cut hole support is anchor cable + anchor rod + steel belt support. First use the drilling rig to construct two rows of fracturing boreholes 2 on the inner roof / top coal 1 of the cut hole 10, and the fracturing boreholes 2 near the front side of the cut hole 5 are arranged obliquely to the advancing direction of the coal mining face. The fracturing drill holes 2 near the auxiliary side of the hole are arranged vertically to the roof / top coal 1; a row of fracturing drill holes 2 is arranged near the fro...

Embodiment 2

[0027] Embodiment two: if Figure 5 As shown, the thickness of the coal seam in a mine is 7.25-20.19m, with an average of 11.17m, the thickness of pure coal is 4.3-19.34m, with an average of 10.02m, containing 2-10 layers of gangue, and the thickness of gangue is 0.2-6.8m, with an average of 1.15m. Single layer thickness 0.05 ~ 1m. The lithology of gangue is: gray-brown kaolinite, gray-black carbonaceous mudstone, mudstone, and local dark gray siltstone. Laoding is gray-white, dark gray, variegated siltstone, fine sandstone, medium-grained sandstone, coarse sandstone, and pebble-bearing coarse sandstone alternately occurring. The main composition is quartz, followed by feldspar and dark minerals. The cementation is dense and hard. The working face is arranged in three lanes, adopting the ventilation mode of "inlet, one back and one exhaust". The roof high suction lane 14 is excavated and arranged along the roof. 20m. The height of the cut hole 10 is 3.5m, the thickness of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com