Thick-specification acid-corrosion-resisting X65 pipeline steel plate and manufacturing method thereof

A manufacturing method and acid-resistant technology, which is applied in the field of pipeline steel manufacturing, can solve the problems of large oxygen blowing volume, insufficient wall thickness and low-temperature crack arrest toughness, and affect the overall performance, and achieve good acid corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

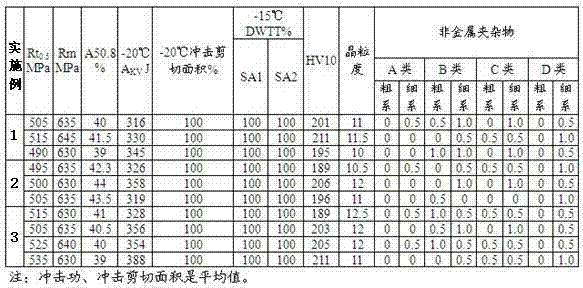

[0031] The present invention will be further described below in conjunction with Embodiment 1-3.

[0032] Table 1 and Table 2 show the component distribution ratio (%) of each embodiment of the present invention, the component is % by weight, and the balance is Fe.

[0033] Table 1 embodiment 1-3 chemical composition

[0034] ,

[0035] Table 2

[0036] .

[0037] According to the composition design requirements of the steel plate of the present invention, the KR molten iron is pre-desulfurized, the top and bottom of the converter are combined blowing, the LF furnace is heated and heated, the temperature is uniform, and the alloy is fine-tuned; the RH furnace is vacuum-circulated and degassed to ensure that the pure degassing time is greater than 10 minutes. At the same time, an appropriate amount of pure calcium wire is fed to denature the inclusions; continuous casting uses low-carbon steel mold slag, and Ar gas is blown throughout the process to protect the casting a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com