Method for recovering tungsten from tungsten-containing fluorite mine

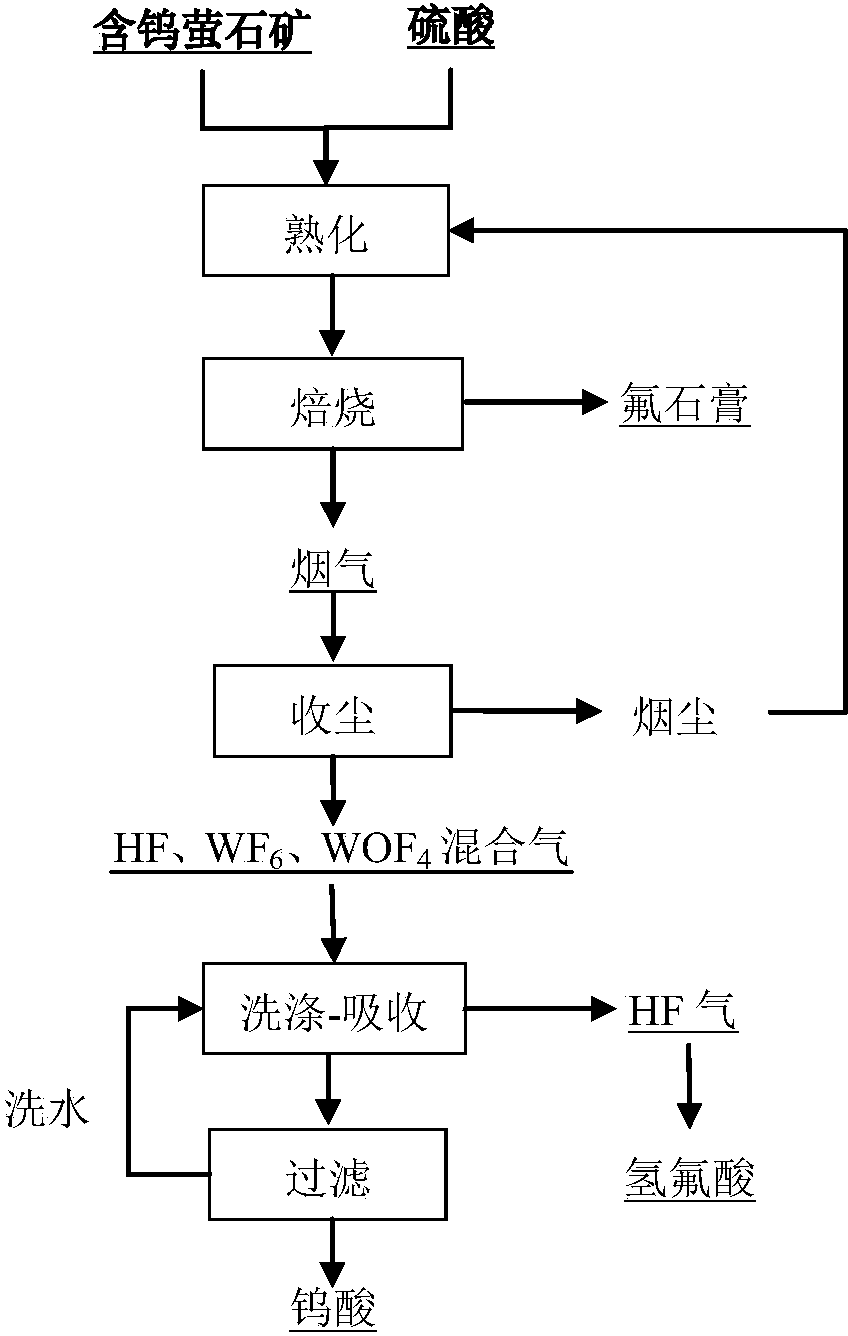

A technology of fluorite ore and tungstic acid, applied in the field of tungsten recovery, to achieve the effect of reducing investment, saving resources and improving the recovery rate of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Fluorite concentrate containing tungsten (containing CaF 2 96.5%, WO 3 0.45%) was mixed with concentrated sulfuric acid, the acid-mineral ratio was controlled at 1:1, aged at 150°C for 0.5h, and then roasted at 500°C for 1h. At this time, the volatilization rate of fluorine reaches 92%, and that of tungsten reaches 65%.

Embodiment 2

[0034] Fluorite concentrate containing tungsten (containing CaF 2 96.5%, WO 3 0.45%) was mixed with concentrated sulfuric acid, the acid-mineral ratio was controlled at 1.2:1, aged at 150°C for 1h, and then roasted at 250°C for 6h. At this time, the volatilization rate of fluorine reaches 95%, and that of tungsten reaches 75%.

Embodiment 3

[0036] Fluorite concentrate containing tungsten (containing CaF 2 96.5%, WO 3 0.45%) was mixed with concentrated sulfuric acid, the acid-mineral ratio was controlled at 1.5:1, aged at 150°C for 1h, and then roasted at 300°C for 10h. At this time, the volatilization rate of fluorine reaches 97%, and that of tungsten reaches 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com