Polymer nano-silica temperature-resistant, salt-tolerant and fluid loss reducing agent and preparation method thereof

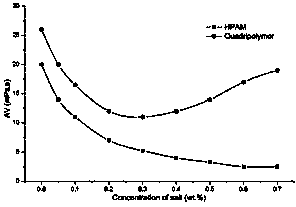

A technology of nano-silicon dioxide and water loss reducing agent, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of unsatisfactory water loss reducing effect, poor temperature and salt resistance of treatment agent, etc. Achieve the effects of good water solubility and dispersibility, improved temperature and salt resistance, and new properties of strong high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

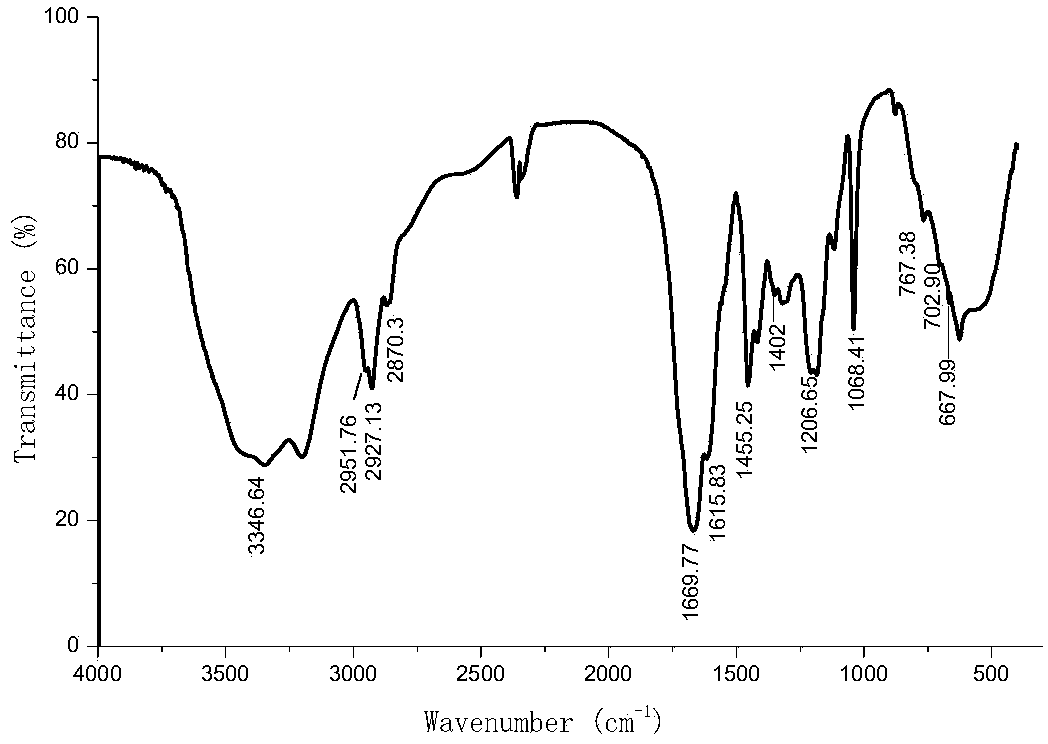

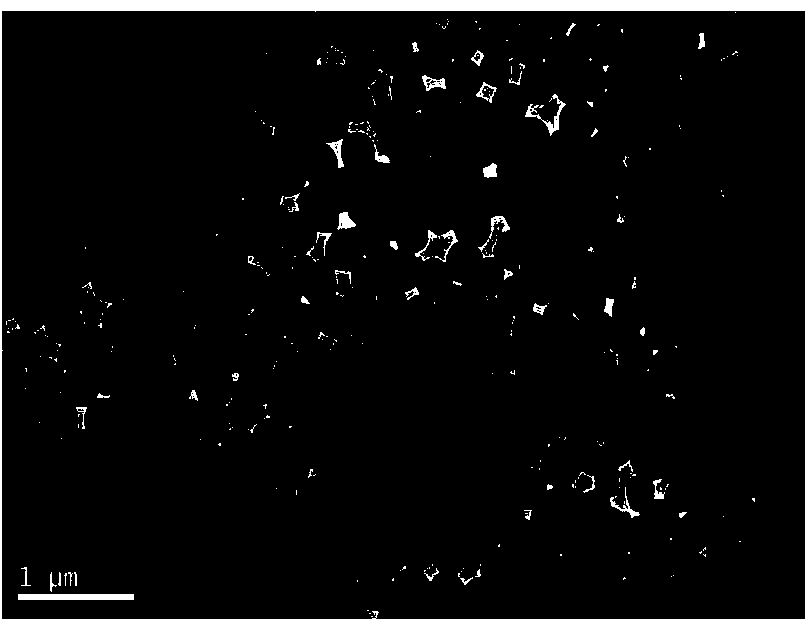

Method used

Image

Examples

Embodiment

[0038] The first step: Synthesis of amphiphilic block hydrophobic association polymer poly[styrene-b-acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, maleic anhydride].

[0039] ①Dissolve 20.7g of 2-acrylamide-2-methylpropanesulfonic acid in 50mL of deionized water, place the container in an ice bath, neutralize with 15% sodium hydroxide, adjust the pH to 8, and generate 2 - Sodium acrylamide-2-methylpropanesulfonate.

[0040] ② Pour a certain amount of deionized water into another beaker and place it in a water bath at 50°C, then put 4.9g of maleic anhydride into the beaker to fully dissolve it.

[0041] ③ Add a certain amount of acrylamide and deionized water into a four-necked flask equipped with a stirrer and a constant pressure drop funnel, stir and dissolve it, add 5g of sodium lauryl sulfate, and then add a certain amount of benzene according to the feeding ratio. Ethylene, stirred into a transparent microemulsion, heated to 50 ° C.

[0042] ④ Control the total ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com