Method for preparing high-viscosity modified guar gum

A guar gum, high viscosity technology, applied in the field of preparation of high viscosity modified guar gum, can solve the problems of complex synthesis steps, low viscosity, low degree of product substitution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

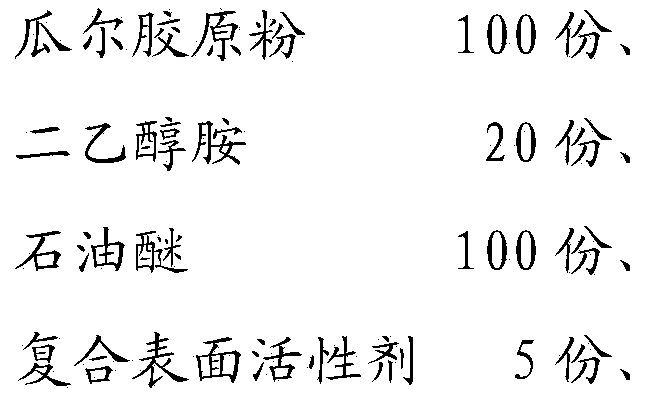

Embodiment 1

[0019] (1) Slowly add guar collagen powder into a 10wt% diethanolamine aqueous solution, and then add petroleum ether within 1 hour to obtain an alkalized guar gum solution;

[0020] (2) Add composite surfactant to the above alkalized guar gum solution, then add dimethylaminoethyl methacrylate benzyl quaternary ammonium chloride within 2 hours, react at 50°C, and wash the product after the reaction , neutralization, suction filtration, drying, and pulverization to obtain the high-viscosity modified guar gum.

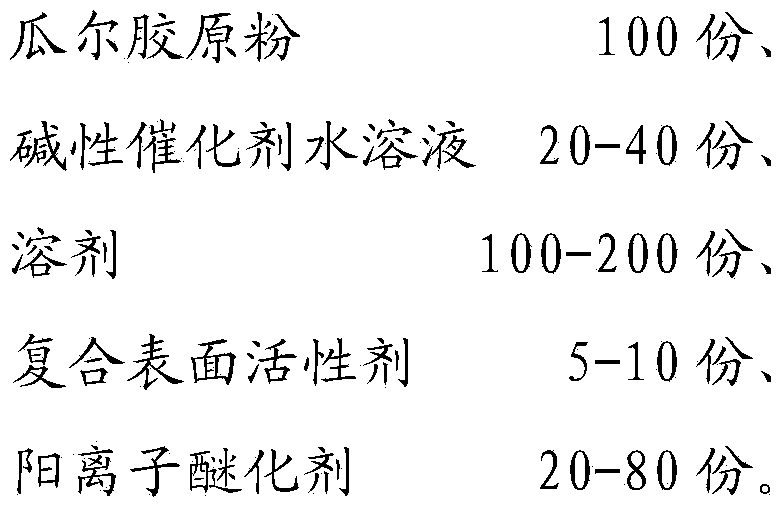

[0021] The parts by weight of each raw material in the above-mentioned steps are as follows:

[0022]

[0023] 20 parts of dimethylaminoethyl methacrylate benzyl quaternary ammonium chloride.

[0024] The composite surfactant is compounded by sorbitan monooleate (Span 80) and sodium oleate in a weight ratio of 1:1.

[0025] According to GB12309-90, the cationic substitution degree is 0.7, and the viscosity (NDJ-1 viscometer, 25°C 4# rotor 60rpm) is 6200mPa.s.

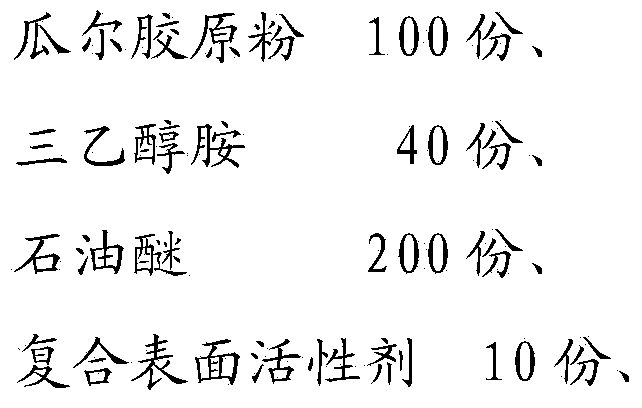

Embodiment 2

[0027] (1) Slowly add guar collagen powder into an aqueous solution of triethanolamine with a concentration of 20wt%, and then add petroleum ether within 1-2 hours to obtain an alkalized guar gum solution;

[0028] (2) Add composite surfactant to the above-mentioned alkalized guar gum solution, then add dimethylaminoethyl acrylate monochloromethane quaternary ammonium within 3 hours, and react at 70°C. After the reaction, the product is washed and neutralized. and, suction filtration, drying, and pulverization to obtain the high-viscosity modified guar gum.

[0029] The parts by weight of each raw material in the above-mentioned steps are as follows:

[0030]

[0031] 80 parts of dimethylaminoethyl acrylate monochloromethane quaternary ammonium.

[0032] The composite surfactant is compounded by sorbitan monolaurate (Tween 21) and triethanolamine oleate at a ratio of 1:2.

[0033] According to GB12309-90, the cationic substitution degree is 0.85, and the viscosity (NDJ-1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com