Continuous synthesis method of low-carbon-chain perfluoroalkyl iodide

A technique for the synthesis of perfluoroalkyl iodides, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, and chemical recovery. It can solve the problems of limited application, accumulation of reaction heat, and high cost, and achieve simplified production processes and reduced production costs. Good effect of cost and composition distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

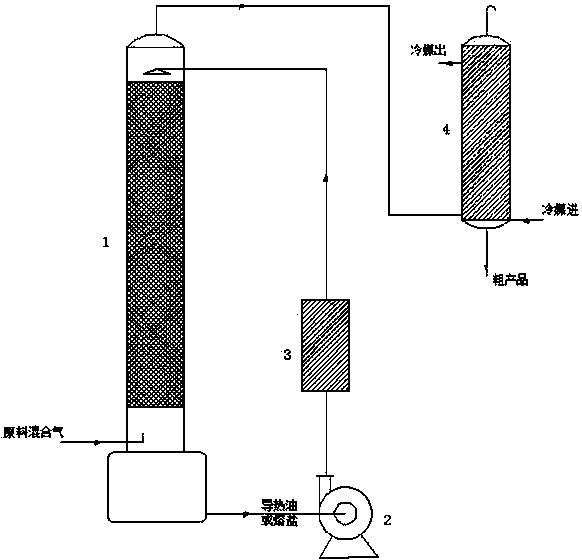

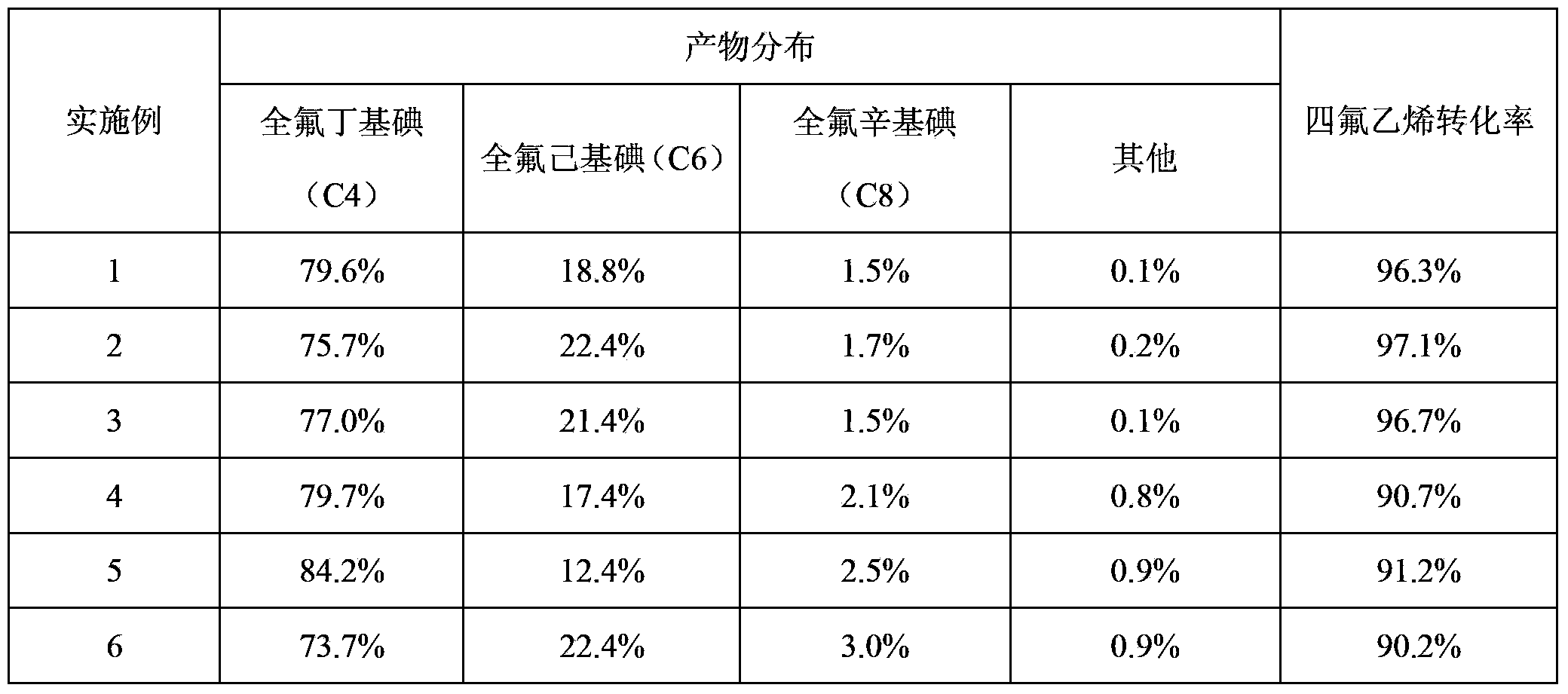

[0035] In packed tower 1, heat transfer oil containing 300 mesh copper powder (brand WD-350, Changzhou Changcheng Energy Equipment Co., Ltd.) is circulated from the top of the tower to the bottom of the tower, and the mass ratio of heat transfer oil to copper powder is 1:0.005. The heat conduction oil is heated up to 340° C. through the heater 3, and pentafluoroiodoethane and tetrafluoroethylene are continuously fed into the packed tower 1 through the flow meter, and the flow rates are 400ml / min and 50ml / min respectively. The product is continuously extracted from the top of the packed tower 1, cooled by the condenser 4 and analyzed by gas chromatography. The reaction results are shown in Table 1.

Embodiment 2

[0037] In the packed tower, heat transfer oil containing 250 mesh copper powder (brand WD-350, Changzhou Changcheng Energy Equipment Co., Ltd.) circulates from the top of the tower to the bottom of the tower. The mass ratio of heat transfer oil to copper powder is 1:0.01, which will conduct heat The oil is heated up to 300°C through the heater 3, and pentafluoroiodoethane and tetrafluoroethylene are continuously introduced into the packed tower 1 through the flowmeter, and the flow rates of pentafluoroiodoethane and tetrafluoroethylene are 400ml / min and 45ml / min respectively. min. The product is continuously extracted from the top of the packed tower 1, cooled by the condenser 4 and analyzed by gas chromatography. The reaction results are shown in Table 1.

Embodiment 3

[0039] In the packed tower, heat transfer oil containing 200 mesh copper powder (brand WD-350, Changzhou Changcheng Energy Equipment Co., Ltd.) is circulated from the top of the tower to the bottom of the tower. The mass ratio of heat transfer oil to copper powder is 1:0.05, which will conduct heat The oil is heated up to 280°C through the heater 3, and pentafluoroiodoethane and tetrafluoroethylene are continuously introduced into the packed tower 1 through the flowmeter, and the flow rates of pentafluoroiodoethane and tetrafluoroethylene are 400ml / min and 40ml / min respectively. min. The product is continuously extracted from the top of the packed tower 1, cooled by the condenser 4 and analyzed by gas chromatography. The reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com