Method for realizing catalytic wet oxidation of wastewater containing organic substances

A technology that catalyzes wet oxidation and organic matter, applied in chemical instruments and methods, physical/chemical process catalysts, catalyst carriers, etc., can solve the problem of low catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

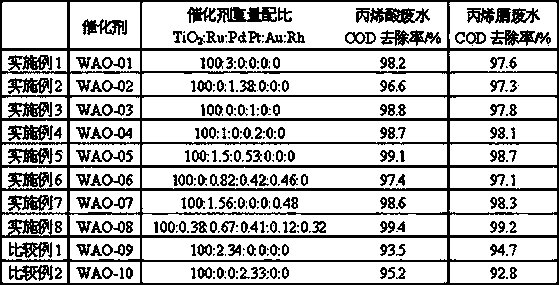

Embodiment 1

[0017] Using anatase-type nano-titanium dioxide powder and NaOH solution as raw materials, 20 g of nano-titanium dioxide powder and 500 mL of NaOH (10 mol / L) solution were mixed in a 1 L autoclave by hydrothermal method, and stirred at 100 ° C for 48 h. After the mixed solution was centrifuged, the solid precipitate was washed once with 1mol / L HCl solution, and then washed to neutrality with distilled water, and the obtained carrier precursor was dried in an oven at 100°C for 24 hours to obtain titanium dioxide nanotubes; 5g titanium dioxide The equal volume of nanotubes was impregnated in 0.3750g RuCl 3 ﹒ nH 2 O in aqueous solution for 12 h, and then dried in an oven at 100 °C for 12 h, and the obtained catalyst precursor was reduced for 3 h at 350 °C in a hydrogen atmosphere to prepare Ru / TiO 2 Catalyst WAO-01. In a 1L autoclave, with 4g Ru / TiO 2 As a catalyst, treat 600mL of acrylic acid wastewater with a COD of 28600mg / L, react at 200°C and an oxygen pressure of 5MPa f...

Embodiment 2

[0020] In a 1L autoclave, 20g of nano titanium dioxide powder and 500mL of NaOH (1mol / L) solution were mixed and stirred at 180°C for 48h. After the mixed solution was centrifuged, the solid precipitate was washed once with 1mol / L HCl solution, and then washed to neutrality with distilled water, and the obtained carrier precursor was dried in an oven at 100°C for 24 hours to obtain titanium dioxide nanotubes; 5g titanium dioxide The equal volume of nanotubes was impregnated with 0.1150g PdCl 2 in the aqueous solution for 12h, dried in an oven at 100°C for 12h, and the obtained catalyst precursor was reduced for 3h in a hydrogen atmosphere at 550°C to obtain Pd / TiO 2 Catalyst WAO-02. In a 1L autoclave, with 4g Pd / TiO 2 As a catalyst, treat 600mL of acrylic acid wastewater with a COD of 28600mg / L, react at 250°C and an oxygen pressure of 8MPa for 120min, and the COD removal rate is 96.6%; treat 600mL of industrial acrylonitrile wastewater with a COD of 29600mg / L, at 260°C, Un...

Embodiment 3

[0023] In a 1L autoclave, mix 20g of nano titanium dioxide powder and 500mL of 6mol / L NaOH solution, and stir at 130°C for 48h. After the mixed solution was centrifuged, the solid precipitate was washed once with 1mol / L HCl solution, and then washed to neutrality with distilled water, and the obtained carrier precursor was dried in an oven at 100°C for 24 hours to obtain titanium dioxide nanotubes; 5g titanium dioxide The nanotubes were impregnated with equal volume in the solution containing 0.1250g H 2 PtCl 6 12h in the aqueous solution, and then dried in an oven at 100°C for 12h, the obtained catalyst precursor was reduced at 600°C for 3h in a hydrogen atmosphere to obtain Pt / TiO 2 Catalyst WAO-03. In a 1L autoclave, with 4g Pt-Pd / TiO 2 As a catalyst, treat 600mL of acrylic acid wastewater with a COD of 28600mg / L, react at 160°C and an oxygen pressure of 4MPa for 30min, and the COD removal rate is 98.8%; treat 600mL of industrial acrylonitrile wastewater with a COD of 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com