Silicon block cutting method and cutting device thereof

A cutting method and a technology of a cutting device, which are applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of easy generation of chips, gaps, and surface loss of silicon wafers, so as to improve stability, reduce shaking, and reduce The effect of edge collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

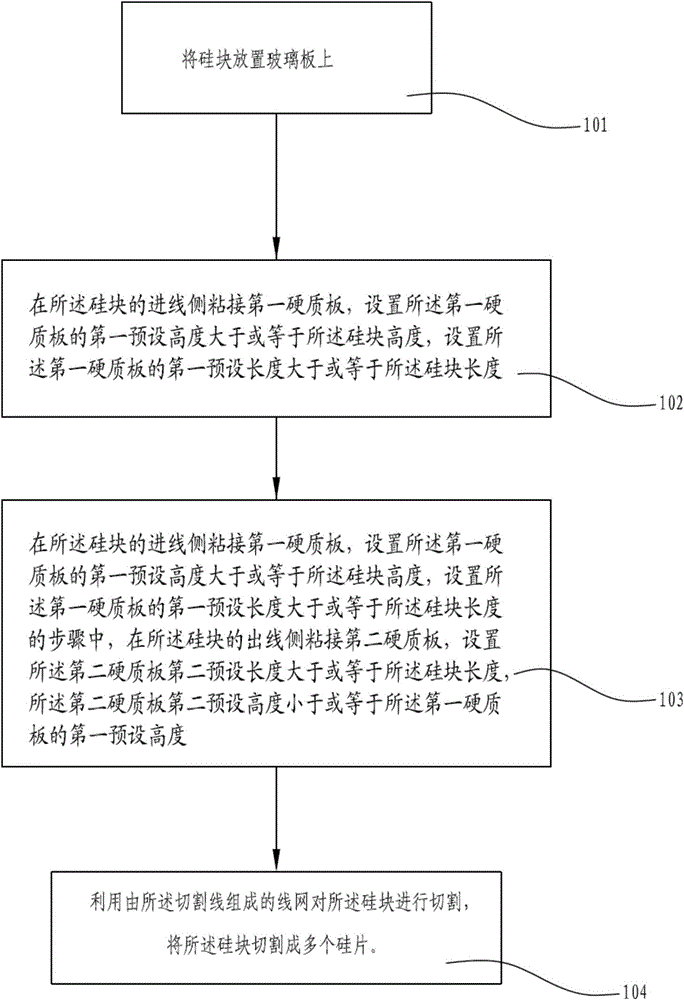

[0027] see figure 1 , a silicon block cutting method according to Example 1 provided in the implementation mode of the present invention. The method includes the following steps:

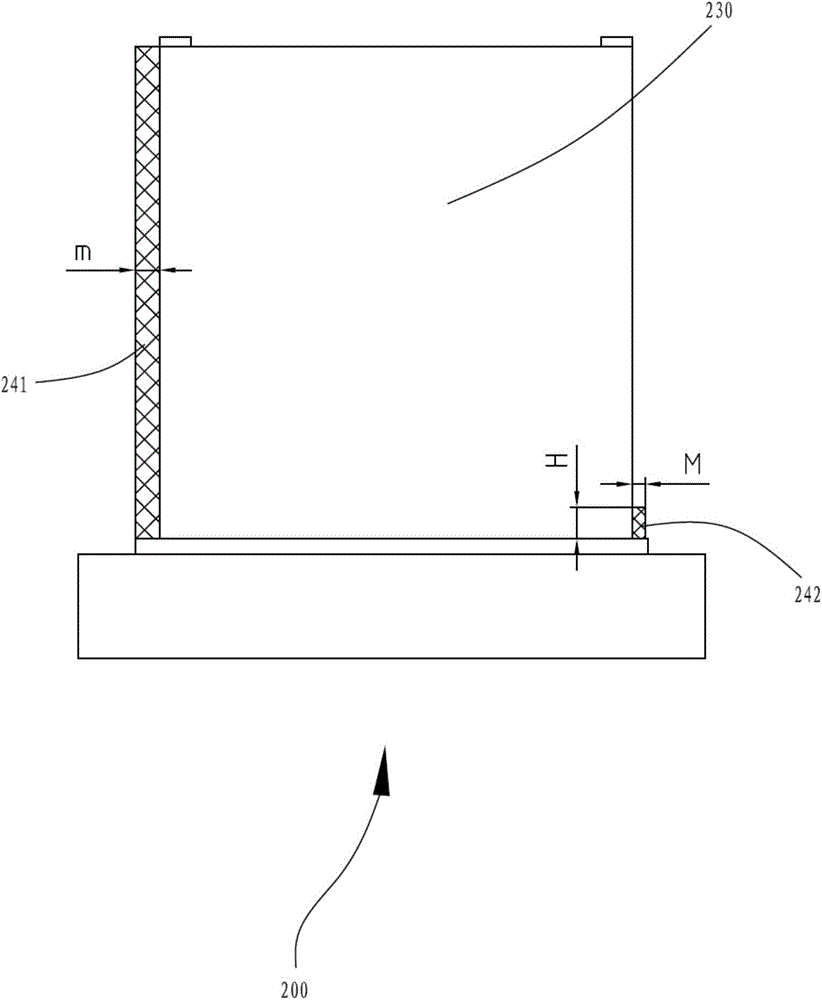

[0028] Step 101: Place the silicon block on the glass plate. In this embodiment, the silicon block has a length of 480 mm, a width of 150 mm, and a height of 156 mm, and the glass plate has a length of 480 mm, a width of 165 mm, and a thickness of 5 mm. Certainly, in other implementation manners, the silicon block and the glass plate may also have other dimensions. Specifically, the bottom surface of the silicon block is coated with glue. And place the bottom surface coated with glue on the glass plate in the center, and the length direction of the silicon block is consistent with the length dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com