Low-carbon environmental friendly deformation-prevention door sheet material

A low-carbon, environment-friendly and anti-deformation technology, which is applied in the direction of wood processing appliances, wooden veneer joints, layered products, etc. Cooling effect, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

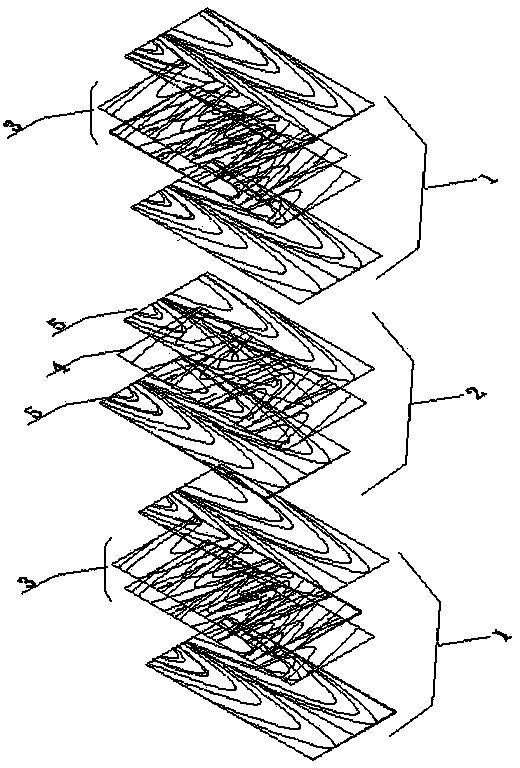

[0019] A low-carbon environment-friendly anti-deformation door panel, comprising a facade layer 1, a middle layer 2, an inner layer 3, a synthetic board 4, a transverse grain lath 5, a longitudinal grain lath 6 and other components, wherein the middle layer 2 is evenly placed Put one layer of horizontal texture lath 5, the inner layer 3 of the facade layer 1 or the surface layer 1 is put into the second layer of horizontal texture lath 5, the middle layer 2 is put into the longitudinal texture arrangement of lath 6, the facade layer 1, the middle layer 2, The inner layer 3, the synthetic board 4, the transverse grain lath 5, and the longitudinal grain lath 6 are uniformly coated with an adhesive, synthesized and extruded.

Embodiment 2

[0021] A low-carbon environment-friendly anti-deformation door panel, the surface layer 1 and the middle layer 2 that need to be bonded are coated with an environmentally friendly E0 grade glue with a concentration of 70%, and the glue is plant glue with zero formaldehyde emission or E0 grade cyanuric glue or Phenolic glue; 5 horizontal grain slats and 6 vertical grain slats are finely processed into the same specifications, and 100% of the cross-section is coated with EO grade environmental protection glue; facade layer 1, 5 horizontal grain slats, and 6 vertical grain slats are the reverse side Glue coating, the middle layer 2 is double-sided glue coating.

Embodiment 3

[0023] A low-carbon environmental protection anti-deformation door panel, the production specification of the middle layer 2 is: 2350mm-2390mm×1170mm-1190mm×10mm-30mm, the production specification of the inner layer 3 is: 1220mm×30mm-50mm×10mm-50mm, and the synthetic board 4 The production specification of the facade layer is: 2400mm×30mm-50mm×10mm-50mm, and the production specification of the facade layer 1 is: 2400mm×1220mm×10mm-20mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com