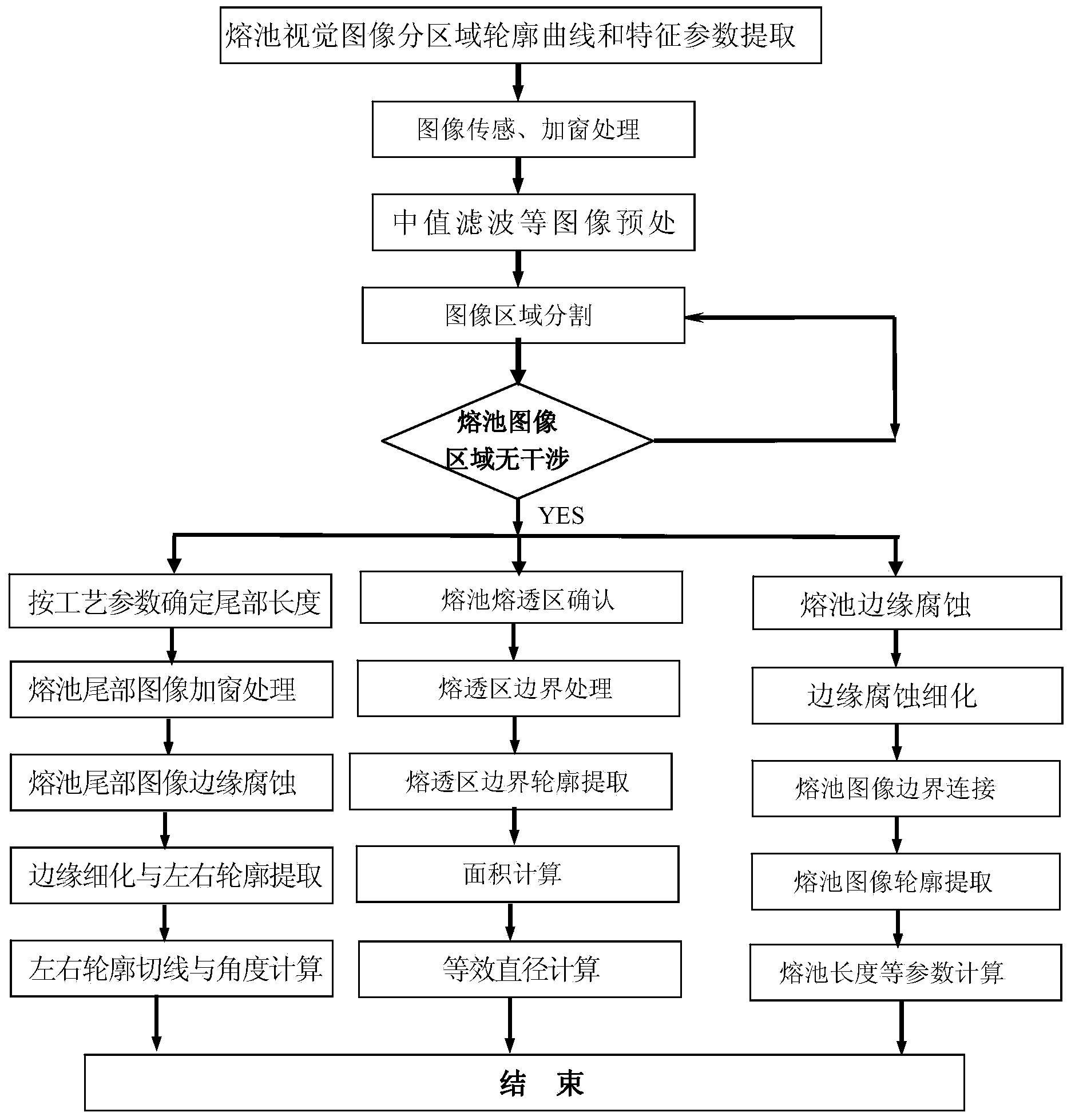

Device and method for double-faced double-arc vertical welding near-infrared vision sensing and penetration control

A double-sided double-arc, visual sensing technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of groove burn-through, complicated process, weld-through defects of weld joints, etc., and achieve the goal of ensuring quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0028] combine figure 1, the plate strip 17 is first leveled in the leveling device 14, planed in the edge trimmer 15, and bent on the three-point bending machine 16 to form a spiral pipe 1 to be welded, and the inner welding torch 9 is fixed on the inner welding seam PTIG head 8, the outer welding gun 11 is fixed on the outer welding seam PTIG head 10, the inner welding gun 9 is positioned at the inner side of the spiral tube 1 to be welded, the outer welding gun is positioned at the outer side of the spiral tube 1 to be welded, and the inner welding gun 9 and the outer welding gun 11 are all aligned The seam to be welded is in the middle, and the inner welding torch 9 and the outer welding torch 11 are arranged coaxially. The outer torch tungsten electrode 13 is arranged on the top, and the axes of the inner torch tungsten electrode 12 and the outer torch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com