Solid catalyst for synthesizing cyclic carbonate and preparation method thereof

A technology of solid catalyst and cyclic carbonate, which is applied in the direction of catalyst carrier, chemical instrument and method, organic compound/hydride/coordination complex catalyst, etc., can solve the problems of high cost and difficulty in catalyst recovery, and achieve low cost , Improving immobilization efficiency, reducing the effect of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

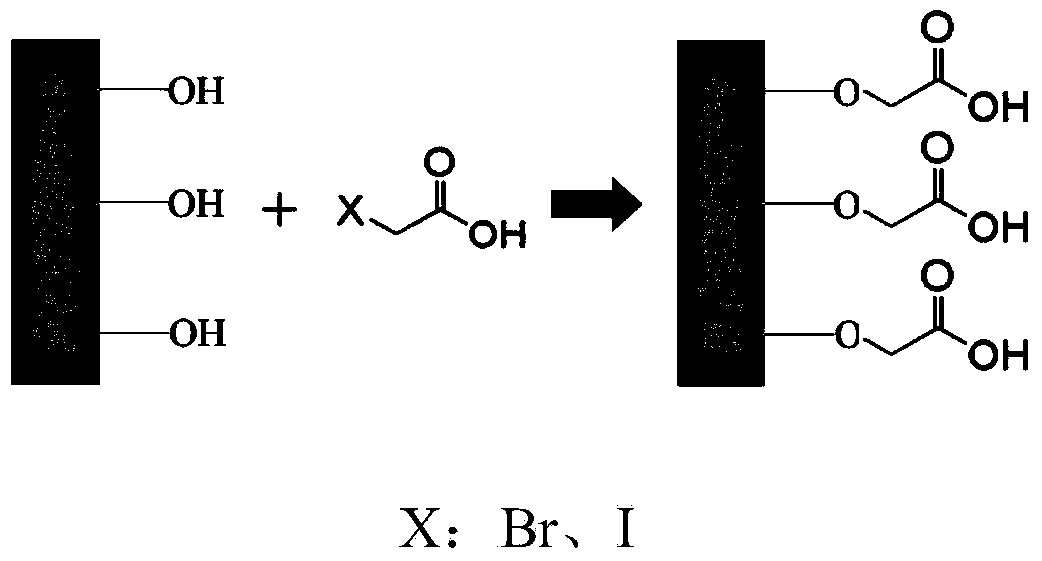

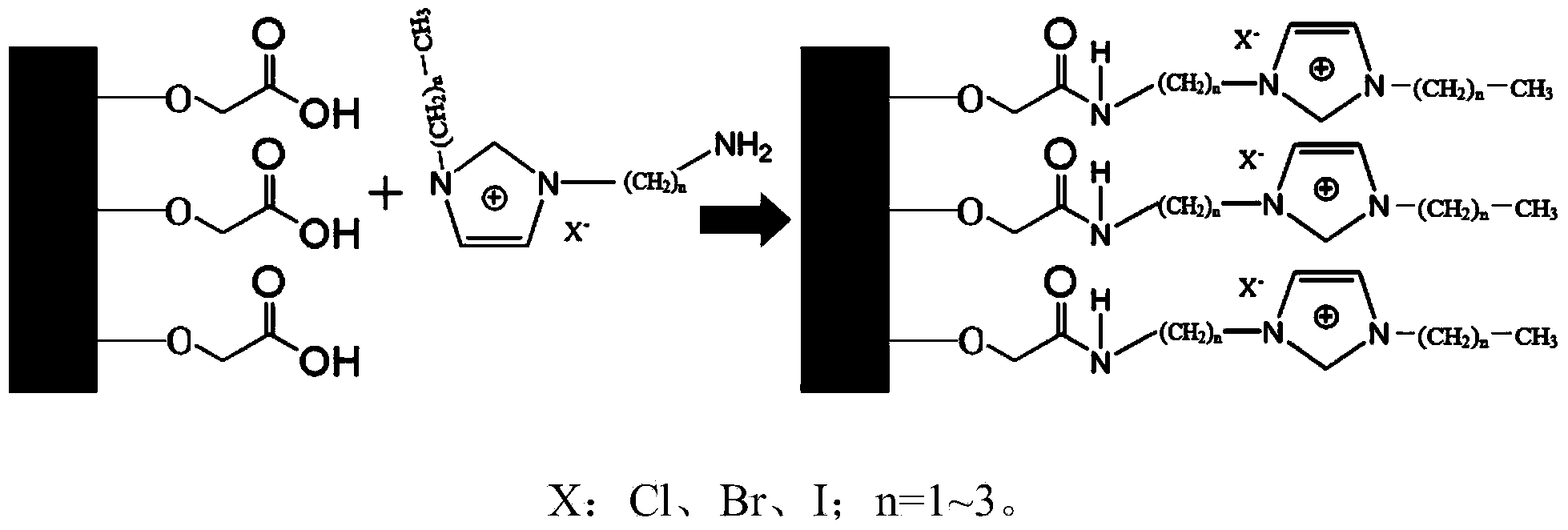

[0029] Add toluene, mesoporous foamed silica and bromoacetic acid in sequence in a closed glass container, wherein the mass ratio of mesoporous foamed silica to toluene is 1:10; the mass ratio of mesoporous foamed silica to bromoacetic acid is 2:1 ; Under the microwave power of 200W for 10 minutes, the surface hydroxyl etherified mesoporous silicon oxide foam can be obtained.

[0030] After filtering, washing and drying, add the solid obtained in the above process into a round bottom flask, then add toluene and 1-aminomethyl-3-ethylimidazolium chloride in sequence, wherein the mass ratio of toluene to solid is 10:1 , the mass ratio of solid to 1-aminomethyl-3-ethylimidazolium chloride salt is 2:1, heated to 50°C with magnetic stirring for 6 hours, and the solid catalyst can be obtained, which is designated as Cat1.

Embodiment 2

[0032] Add toluene, mesoporous foamed silica and bromoacetic acid in sequence in a closed glass container, wherein the mass ratio of mesoporous foamed silica to toluene is 1:20; the mass ratio of mesoporous foamed silica to bromoacetic acid is 5:1 ; Under the microwave power of 200W for 3 minutes, the surface hydroxyl etherified mesoporous silicon oxide foam can be obtained.

[0033] After filtering, washing and drying, add the solid obtained in the above process into a round bottom flask, then add toluene and 1-aminomethyl-3-butylimidazolium bromide successively, wherein the mass ratio of toluene to solid is 20:1 , the mass ratio of solid to 1-aminomethyl-3-butylimidazolium bromide is 4:1, and heated to 50°C with magnetic stirring for 3 hours to obtain a solid catalyst, which is designated as Cat2.

Embodiment 3

[0035] Add toluene, mesoporous foamed silica and iodoacetic acid in sequence in a closed glass container, wherein the mass ratio of mesoporous foamed silica to toluene is 1:10; the mass ratio of mesoporous foamed silica to iodoacetic acid is 6:1 ; Under the microwave power of 200W for 3 minutes, the surface hydroxyl etherified mesoporous silicon oxide foam can be obtained.

[0036]After filtering, washing and drying, add the solid obtained in the above process into a round bottom flask, then add toluene and 1-aminopropyl-3-propylimidazolium bromide successively, wherein the mass ratio of toluene to solid is 10:1 , the mass ratio of solid to 1-aminopropyl-3-propylimidazolium bromide is 2:1, heated to 50°C with magnetic stirring for 2 hours, and the solid catalyst can be obtained, which is designated as Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com