Hydrocracking catalyst containing Ti-P-Beta molecular sieve and preparation method of hydrocracking catalyst

A ti-p-beta and hydrocracking technology, which is applied in the field of hydrocracking catalyst and its preparation, can solve the problems of low naphtha yield, poor performance of zeolite properties, and low selectivity of heavy naphtha , to achieve the effects of reducing coke deposition, promoting overall reaction performance, and improving aromatization and isomerization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

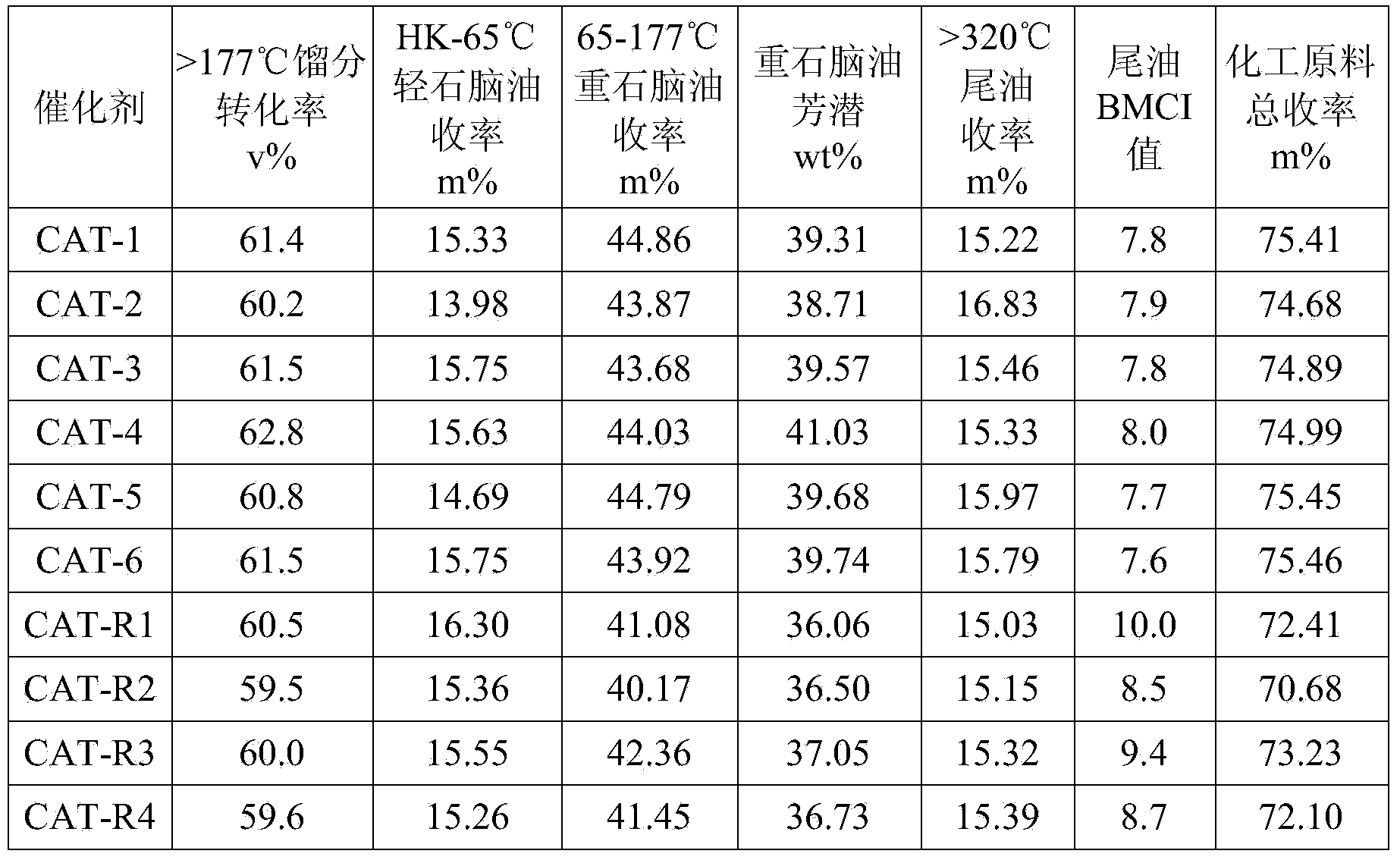

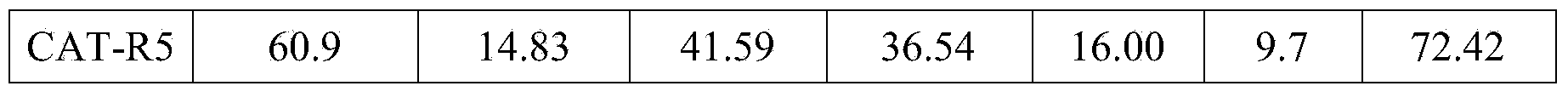

Examples

Embodiment 1

[0038] The present embodiment provides a kind of hydrocracking catalyst containing Ti-P-Beta molecular sieve, and its preparation method comprises the following steps:

[0039] (1) Preparation of Ti-P-Beta molecular sieve:

[0040] (1a), with NaBeta molecular sieve: water: NH 4 Cl=1:10:0.9 mass ratio, NaBeta molecular sieve, water and NH 4 Cl is made into an ion exchange liquid, and the pH value of the ion exchange liquid is adjusted to about 3 with 0.5mol / L HCl solution, and then the ion exchange is carried out at 80°C for 3 hours, followed by suction filtration and washing to neutrality, and at 95°C After drying at 550°C for 10 hours, then roasting at 550°C for 2 hours to obtain a deaminated molecular sieve, which is denoted as Beta(1) molecular sieve;

[0041] (1b), 2.41g Ti(SO4) 2 Dissolve in an appropriate amount of distilled water to make an impregnating solution, slowly pour the impregnating solution into 60g Beta(1) molecular sieve, stir continuously to achieve equa...

Embodiment 2

[0048] The present embodiment provides a kind of hydrocracking catalyst containing Ti-P-Beta molecular sieve, and its preparation method comprises the following steps:

[0049] (1) Preparation of Ti-P-Beta molecular sieve:

[0050](1a), with NaBeta molecular sieve: water: NH 4 Cl=1:10:0.8 mass ratio, NaBeta molecular sieve, water and NH 4 Cl is made into an ion exchange liquid, and the pH value of the ion exchange liquid is adjusted to about 3 with 0.5mol / L HCl solution, and then the ion exchange is carried out at 90°C for 3 hours, followed by suction filtration and washing to neutrality, and at 95°C After drying at 550°C for 10 hours, and then roasting at 550°C for 4 hours, deaminated molecular sieves were obtained, which were denoted as Beta(2) molecular sieves;

[0051] (1b), 3.01g Ti(SO4) 2 Dissolve in an appropriate amount of distilled water to make an impregnating solution, slowly pour the impregnating solution into 60g of Beta(2) molecular sieves, stir constantly to ...

Embodiment 3

[0057] The present embodiment provides a kind of hydrocracking catalyst containing Ti-P-Beta molecular sieve, and its preparation method comprises the following steps:

[0058] (1) Preparation of Ti-P-Beta molecular sieve:

[0059] (1a), with NaBeta molecular sieve: water: NH 4 Cl=1:10:1 mass ratio, NaBeta molecular sieve, water and NH 4 Cl is made into an ion exchange liquid, and the pH value of the ion exchange liquid is adjusted to about 3 with 0.5mol / L HCl solution, and then the ion exchange is carried out at 85°C for 3 hours, followed by suction filtration and washing to neutrality, and at 95°C After drying at 550°C for 10 hours, it was then calcined for 4 hours to obtain a molecular sieve after deammonization, which was denoted as Beta(3) molecular sieve;

[0060] (1b), 9.04g Ti(SO4) 2 Dissolve in an appropriate amount of distilled water to make an impregnating solution, slowly pour the impregnating solution into 60g Beta(3) molecular sieves, stir continuously to achi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com