Manufacturing method of novel FPC

A production method and new technology, which are applied in chemical/electrolytic methods to remove conductive materials, manufacture printed circuits, and manufacture printed circuit precursors, etc., can solve the problems of high difficulty in quality control, many processing procedures, and low production efficiency. Achieve the effect of saving manpower and processing cost, improving safety and reliability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

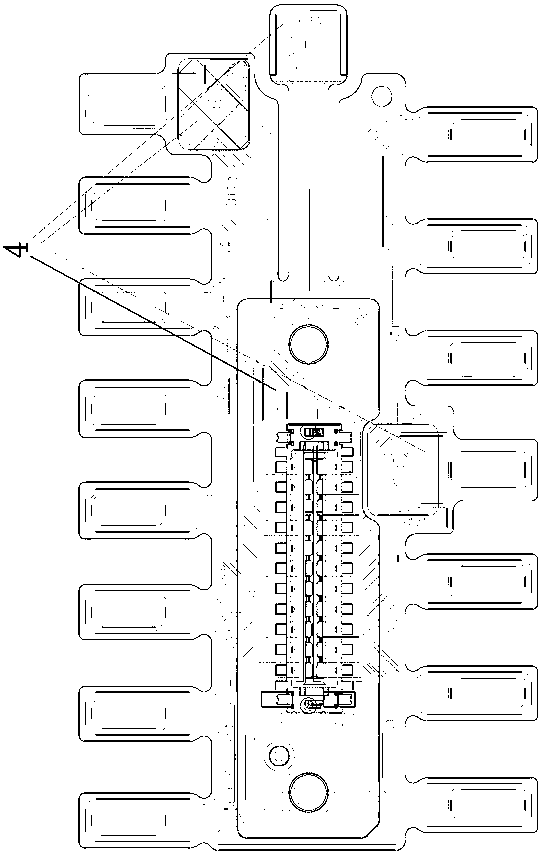

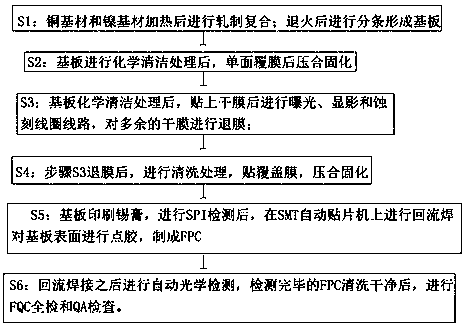

[0024] like Figure 1-3 As shown, the embodiment provided by the present invention, a kind of manufacturing method of novel FPC, comprises the following steps:

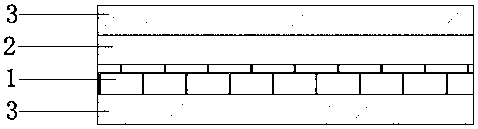

[0025] S1: The copper base material 1 and the nickel base material 2 are heated and combined by rolling; after annealing, they are divided into strips to form substrates. The copper substrate 1 has a thickness of 70 μm, and the nickel substrate 2 has a thickness of 30 μm.

[0026] S2: After the substrate is chemically cleaned, one side is covered with a film and then pressed and cured;

[0027] S3: After the substrate is chemically cleaned, the dry film is pasted, exposed, developed and etched for the coil circuit, and the excess dry film is removed; the front of the substrate is exposed, developed and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com