A method for treating sulfur recovery tail gas by using boiler flue gas ammonia desulfurization

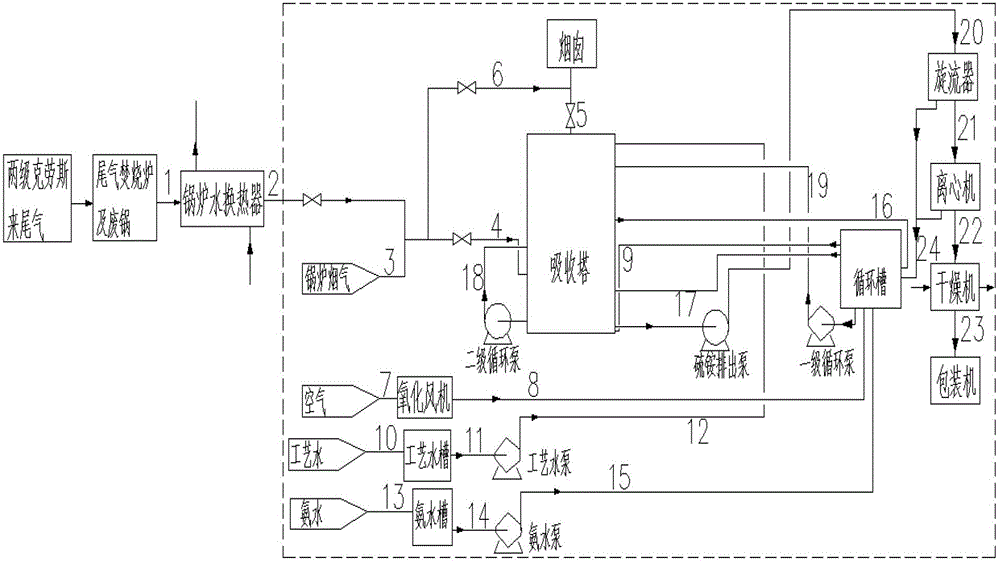

A technology for recovering sulfur from tail gas and boiler flue gas is applied in separation methods, chemical instruments and methods, ammonium sulfate, etc., which can solve the problems of increased operating costs, complex process flow, large floor space, etc., and reduce land occupation. area, guaranteed sulfur recovery rate, and the effect of good sulfur recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The waste ammonia water 13 with a concentration of 15% by weight outside the boundary area is metered into the ammonia water tank for temporary storage. The waste ammonia water 14 is extracted from the ammonia water tank by the ammonia water pump, and the waste ammonia water 15 is sent to the circulation tank through the regulating valve group.

[0070] The process water 10 outside the boundary area is measured and stored in the process water tank. The process water 11 in the process water tank can be sent to various water points through the process water pump, including the water replenishment at the top of the absorption tower, the demister, the tower, and the pump inlets. , Cyclone, centrifuge, water seal of each pump, etc.

[0071] The oxidation fan pressurizes the air 7 to 90~130KPa, where the pressure is mainly determined by overcoming the resistance drop of the solution, so that the oxidized air 8 obtained after pressurization enters the bottom of the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com