Montelukast sodium pulse capsule and preparation method thereof

A technology of Montelukast sodium and capsules, which is applied in the field of Montelukast sodium pulse-release capsules and its preparation, and can solve the problems of no patent reports on the dosage form of Montelukast sodium pulse capsules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

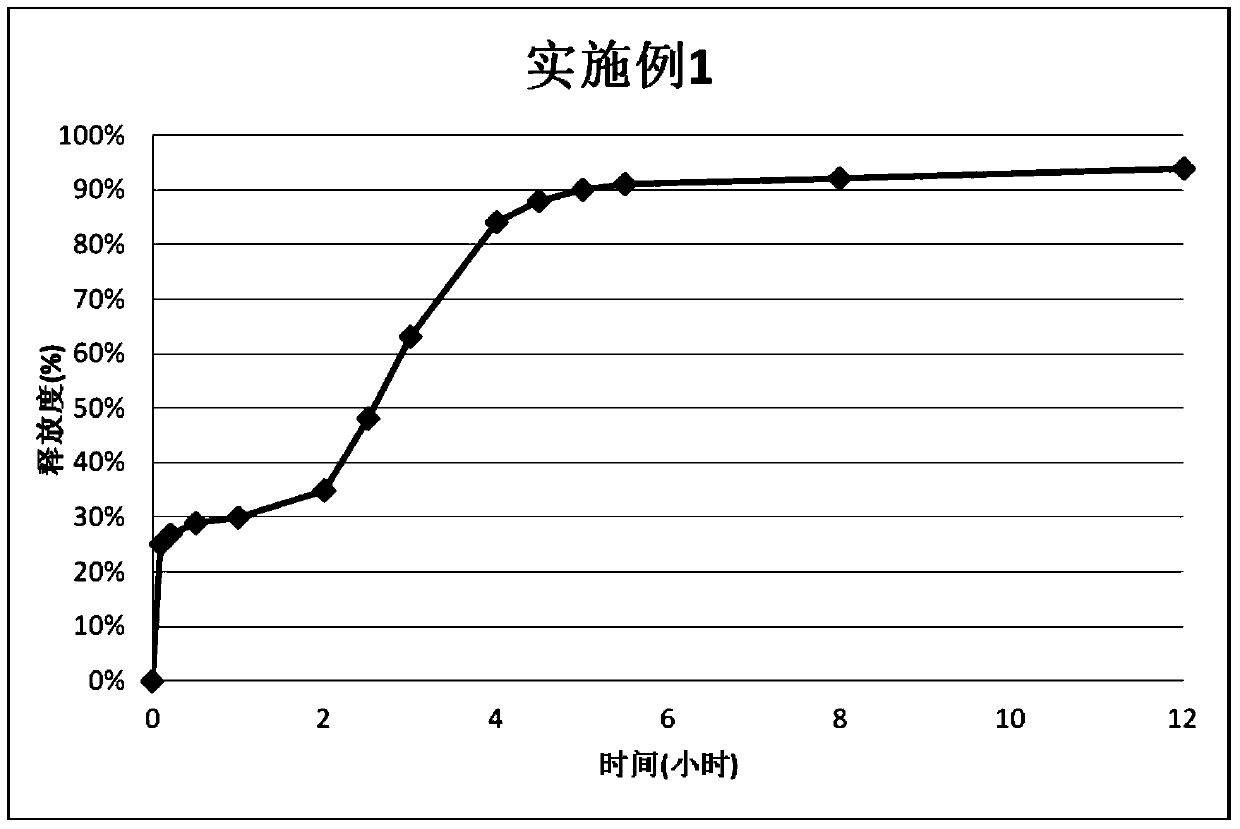

Embodiment 1

[0024] Take 20 g of montelukast sodium, 880 g of lactose (200 mesh), 50 g of hypromellose (EF), and 50 g of croscarmellose sodium; dissolve the hypromellose with an appropriate amount of water, and then add montelukast Sodium, stir evenly; put lactose and croscarmellose sodium in a 4L wet process, first stir at 500rpm, cut and mix at 1000rpm for 180 seconds, then add the aforementioned binder solution containing the main ingredient under the same parameters; add After completion, granulate for an appropriate time, discharge the material, granulate with a 26-mesh oscillating granulator, and then dry to LOD<3.0%, that is, immediate-release granules.

[0025] Then take 30g of montelukast sodium, 690g of lactose (200 mesh), 40g of hypromellose (EF), and 40g of croscarmellose sodium; Sodium wurst, stir evenly; put lactose and croscarmellose sodium in a 4L wet method, first stir at 500rpm, cut and mix at 1000rpm for 180 seconds, and then add the aforementioned binder solution contai...

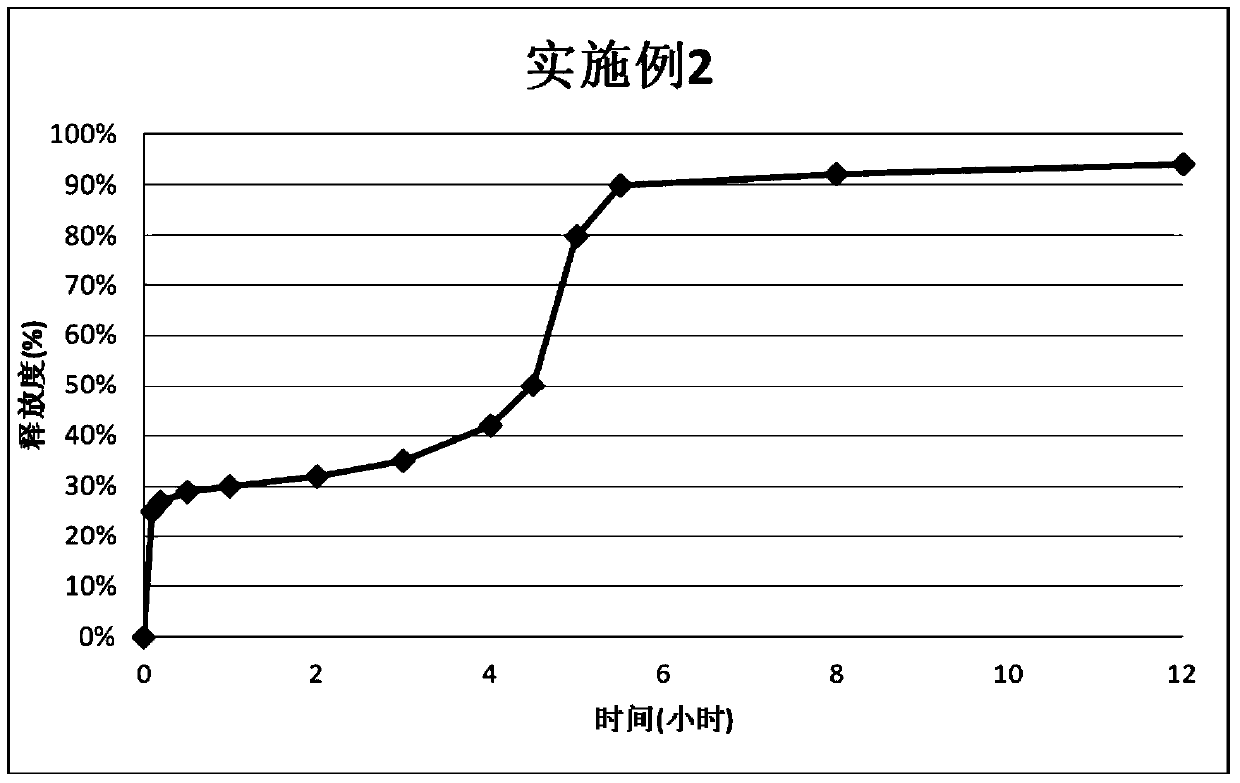

Embodiment 2

[0028] Take montelukast sodium 20g, microcrystalline cellulose 101 type 150g, lactose (200 mesh) 730g, hypromellose (EF) 50g, low-substituted hydroxypropyl cellulose 50g; Dissolve in water, then add montelukast sodium, and stir evenly; put the above-mentioned microcrystalline cellulose, lactose and low-substituted hydroxypropyl cellulose in a 4L wet process, first stir at 500rpm, cut and mix at 1000rpm for 180 seconds, and then mix the above-mentioned Add the binder solution of the main ingredient under the same parameters; after the addition, granulate for an appropriate time, discharge the material, extrude with a 1.0mm sieve, spheronize, and then dry to LOD<3.0%, that is, the speed Shi Xiaowan. Then get 30g of montelukast sodium, 120g of microcrystalline cellulose 101 type, 570g of lactose (200 mesh), 40g of hypromellose (EF), 40g of croscarmellose sodium; Dissolve in an appropriate amount of water, then add montelukast sodium, and stir evenly; put microcrystalline cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com