Novel plastic infusion bag and manufacturing method thereof

A manufacturing method and technology for infusion bags, which are applied in the directions of transportation and packaging, types of packaging items, special packaging items, etc., can solve the problems that affect the self-emptying performance of liquid medicine, the pull ring is easy to break, and the safety and controllability are low. It is beneficial for nurses to operate dosing, improve safety and reliability, and have high safety and controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

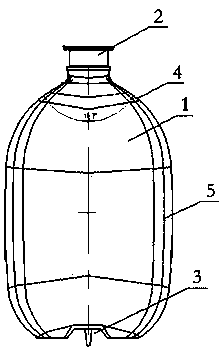

[0060] The ratio of the liquid occupied space of the bag 1 to the reserved dosing space is 1:1.0-1:1.7.

[0061] In specific implementation:

[0062] When the ratio of bag body 1 width to thickness is 2, the ratio of liquid occupied space to reserved dosing space is recommended to be 1:1.5 or 1.6 or 1.7;

[0063] When the ratio of bag body 1 width to thickness is 3, the ratio of liquid occupied space to reserved dosing space is recommended to be 1:1.3 or 1.4 or 1.5;

[0064] When the ratio of bag body 1 width to thickness is 4, the ratio of liquid occupied space to reserved dosing space is recommended to be 1:1.1 or 1.2 or 1.3;

[0065] That is to say, it is ensured that the pressure difference in the bag body will not be too large during the infusion, coupled with the extrusion effect of the outer bag wall atmospheric pressure, it is ensured that the liquid medicine can be discharged completely and at a relatively constant speed.

Embodiment 2

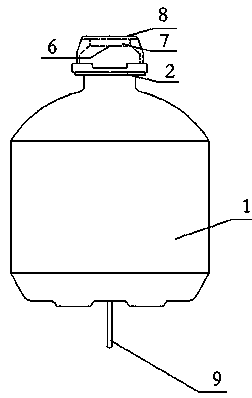

[0067] see figure 2 , a sealed inner cover 6 is provided at the opening 2 of the infusion bag, the material of the sealed inner cover 6 is the same as that of the bag body 1, and it is formed by instant injection molding on another device in the same cycle, which reduces the possibility of pollution and also The possibility of different raw materials contaminating the liquid medicine is reduced; the sealed inner cover 6 is provided with a rubber pad 7, and the outer cover of the cover is provided with an easy-to-tear film 8, which not only has good sealing performance, but also is easy to open and use; the suspension Structure 3 adopts suspension ring 9, during infusion, realizes suspension by it.

Embodiment 3

[0069] The wall thickness of the bag body 1 is thicker than the conventional bag body, which can enhance its ability to resist deformation.

[0070]

[0071] The present invention also provides the manufacture method of this novel plastic transfusion bag, and concrete steps are:

[0072] 1. Prepare ingredients for the bag body 1 and make a preliminary shape;

[0073] 2. Blow molding the preliminarily formed bag body 1;

[0074] 3. Install the guide rib 5 into the side wall of the bag body 1;

[0075] 4. Clean the formed bag body 1 and dry it with ion wind to avoid electrostatic adsorption;

[0076] 5. Filling liquid medicine;

[0077] 6. Weld and seal the sealed inner cover on the 2 openings of the infusion bag;

[0078] 7. Transport to the 10,000-class clean room for sealing of the outer cover.

[0079] The above steps need to be completed within a period of time, which eliminates the storage time of the bag body and reduces the possibility of pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com