A system and construction method for defoaming and density measurement of slurry outside a desulfurization absorption tower

A desulfurization absorption tower, density measurement technology, applied in chemical instruments and methods, separation methods, specific gravity measurement, etc., to achieve the effect of increasing measurement efficiency and accuracy, easy installation and replacement, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

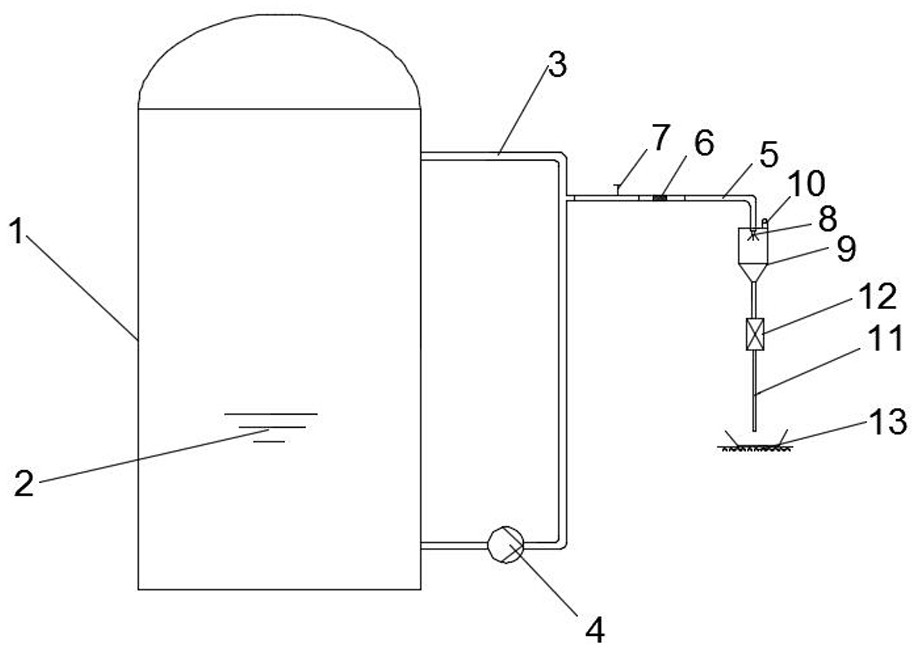

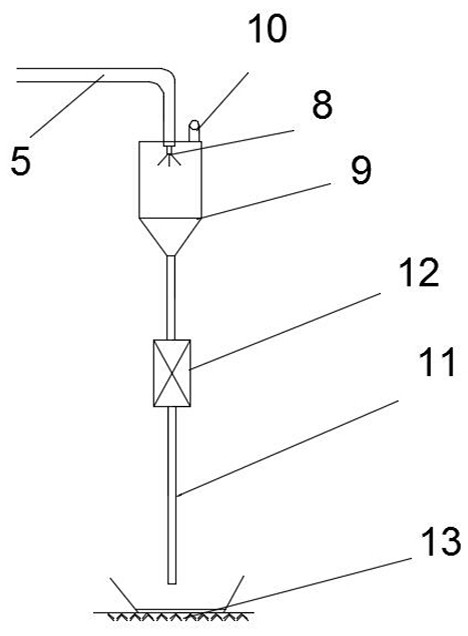

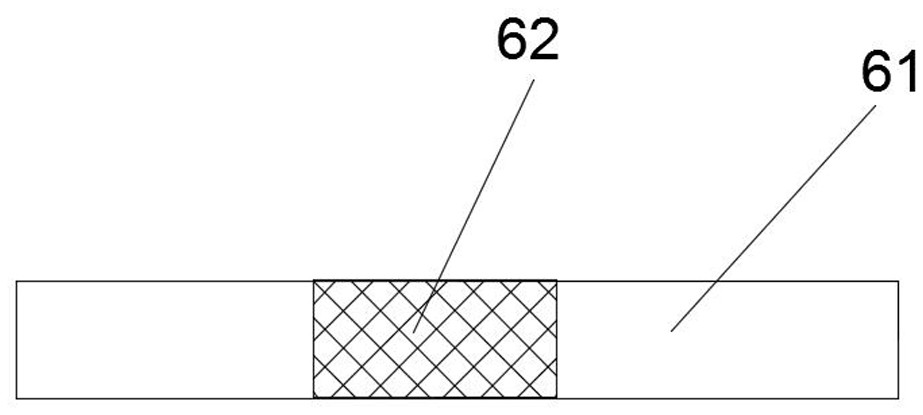

[0032] Such as figure 1 and figure 2 As shown, a slurry defoaming and density measurement system outside the desulfurization absorption tower includes an absorption tower 1, a slurry 2 located in the absorption tower 1, a slurry discharge pipeline 3 and a slurry discharge pump 4 connected to the absorption tower 1, connected to The defoaming pipeline 5 on the slurry pipeline 3, the buffer device 6 connected to the defoaming pipeline 5, the nozzle 8 connected to the downstream end of the defoaming pipeline 5, the defoaming box 9 connected to the bottom of the nozzle 8, the defoaming box 9 connected to the defoaming pipeline The discharge pipe 11 at the bottom of the bubble box 9 , the density meter 12 connected to the discharge pipe 11 and the trench 13 connected to the discharge pipe 11 below.

[0033] In this embodiment, the slurry pipeline 3 is the external circulation pipeline of the absorption tower 1 and the slurry pump 4 is threadedly connected to the circulation pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com