Electrolyte for double-electric-layer capacitor

An electric double layer capacitor and electrolyte technology, applied in the field of electrochemistry, can solve the problems of large equivalent internal resistance, low affinity, and high viscosity of pyridine ionic liquids in electric double layer capacitors, and achieve high surface tension and high viscosity. , the effect of reducing the equivalent internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the glove box, mix propylpyridinium tetrafluoroborate and tridecyltrimethylsilane with a molar ratio of 1:0.04, that is, 5 mol and 0.2 mol respectively, and stir for 30 minutes, tridecane Trimethylsilane is uniformly dispersed in propylpyridinium tetrafluoroborate to obtain an electrolytic solution for electric double layer capacitors.

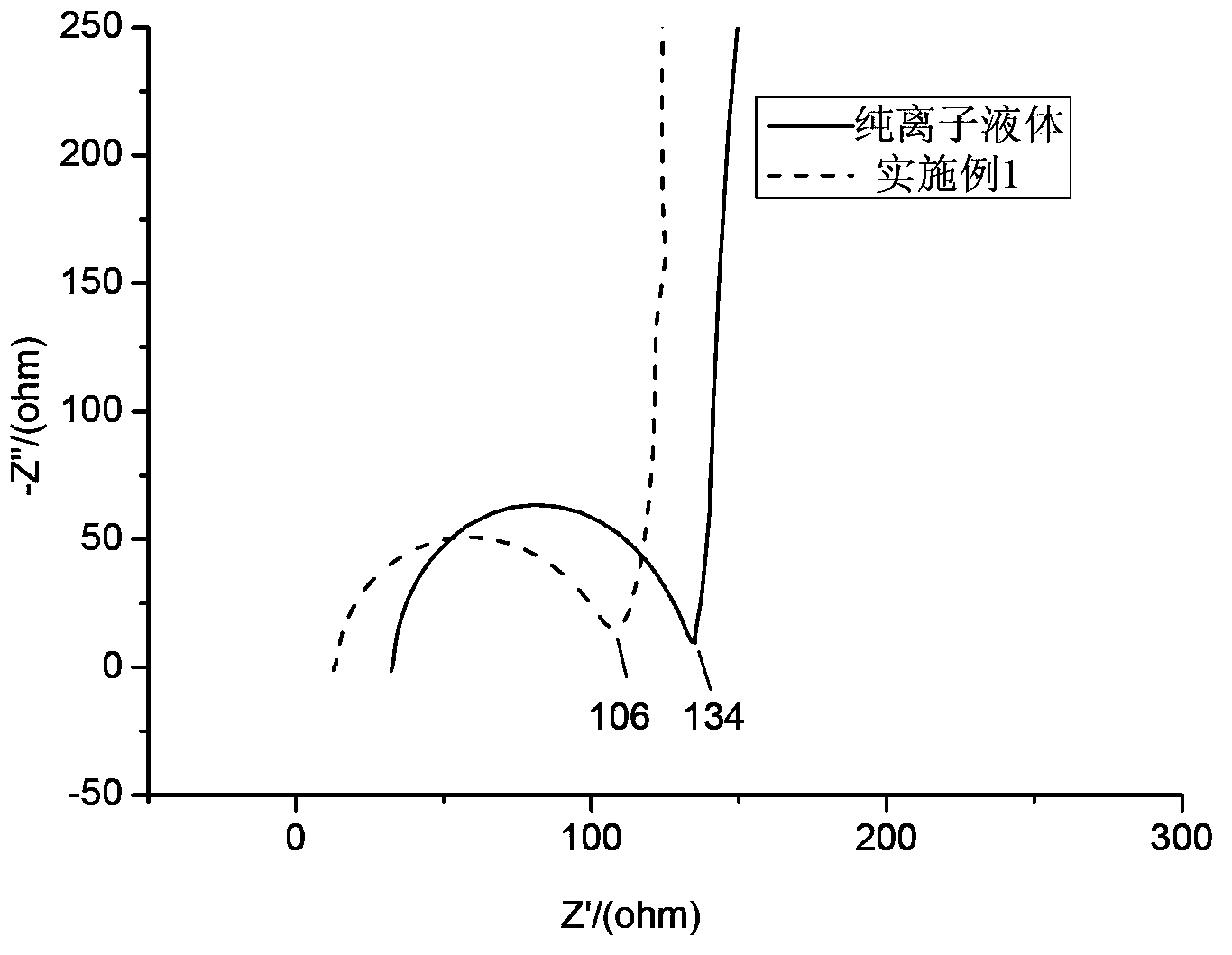

[0022] figure 1 For the electric double layer capacitor using the electrolytic solution for the electric double layer capacitor obtained in Example 1 as the electrolyte (the diaphragm of the capacitor is made of PP material) and the electric double layer capacitor using pure ionic liquid propylpyridine tetrafluoroborate as the electrolyte The AC impedance spectrum of an electric double layer capacitor; where the abscissa is the real part, and the ordinate is the imaginary part (the data measured by the AC impedance is a complex number obtained through mathematical model processing, and the AC impedance spectrum is a complex plane gra...

Embodiment 2-20

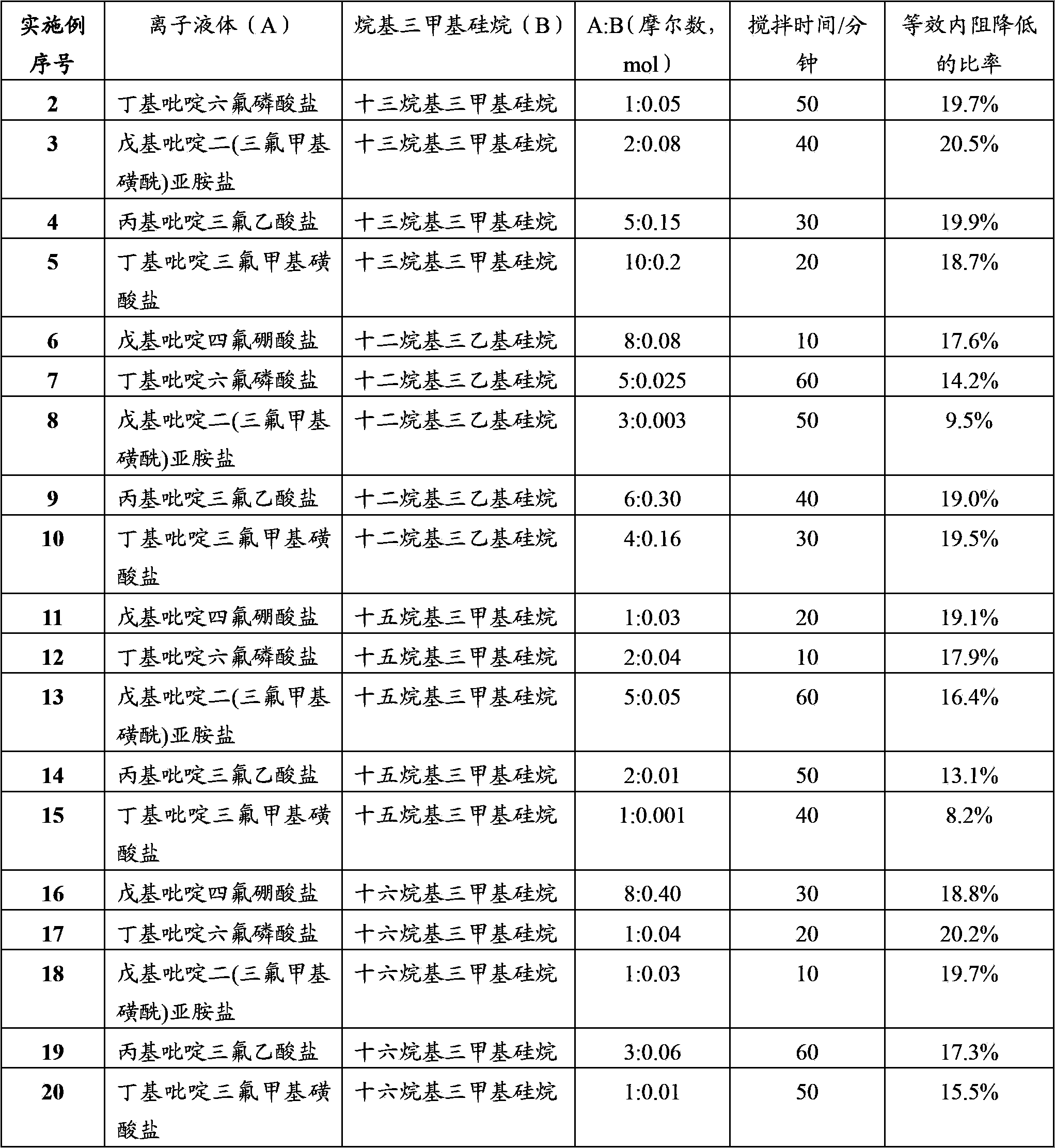

[0024] Embodiment 2-20 sees following form:

[0025]

[0026] Note: In the table,

[0027] 1. A represents ionic liquid, B represents alkyltrimethylsilane; A:B represents the respective moles of A and B, for example, A:B is 2:0.08, which means that the moles of A are 2mol and the moles of B 0.08mol;

[0028] 2. The reduction ratio of the equivalent internal resistance is the ratio of the equivalent internal resistance of the electric double layer capacitor using the electrolyte of this embodiment in the corresponding embodiment to the ionic liquid without adding alkyltrimethylsilane measured under the same conditions The percentage reduction of the equivalent internal resistance of the electric double layer capacitor;

[0029] 3. In Examples 2 to 20, various preparation processes and test conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com