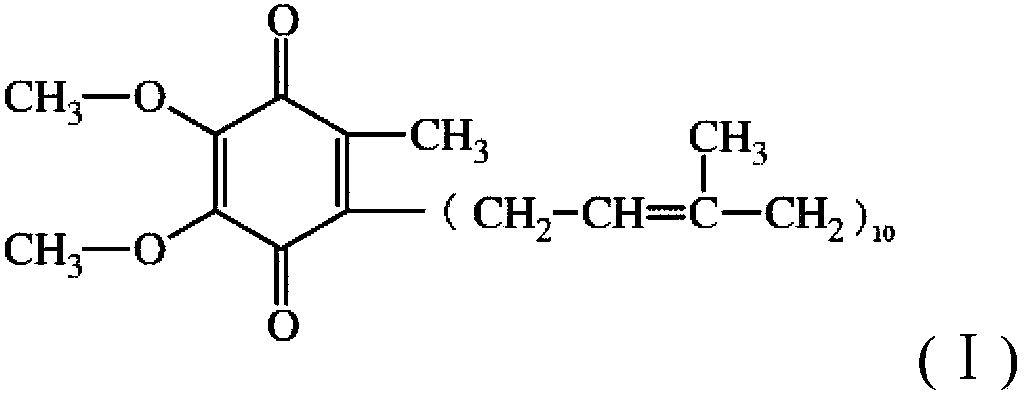

Coenzyme-Q10-production engineered bacteria construction method, engineered bacteria, and application thereof

A construction method and technology for engineering bacteria are applied in the construction field of producing coenzyme Q10 engineering bacteria, which can solve the problem of high cost and achieve the effects of high synthesis capacity, good effect of large-scale production and application, and low pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 produces the construction method of the engineering bacterium of coenzyme Q10

[0036] 1. Genomic DNA was extracted from Rhodobacter sphaeroides (all reagents used were from Biospin Bacterial Genomic DNA Extraction Kit)

[0037] 1. Absorb 0.5-4mL of Rhodobacter sphaeroides (up to 5×109 bacteria, said Rhodobacter sphaeroides were isolated from riverside sludge), centrifuge at 13,500rpm for 1 minute, and absorb the supernatant as much as possible.

[0038] 2. Add 100μL EL Buffer and pipette evenly with a tip.

[0039] 3. Incubate at 37°C for 40 minutes.

[0040] 4. Add 100μL RS Buffer, then add 10μL PK Solution, and mix well.

[0041] 5. Incubate at 56°C for 15 minutes, then remove.

[0042] 6. Add 200μL GA Buffer and mix well.

[0043] 7. Centrifuge at 12000 rpm for 1 minute. Transfer the supernatant to a new 1.5 mL centrifuge tube.

[0044] 8. Add 400μL of BA Buffer and mix well.

[0045] 9. Transfer the mixed liquid to the spin column. Centrifuge a...

Embodiment 2

[0126] The method of embodiment 2 application engineering bacteria production coenzyme Q10

[0127] First-class seeds: Pick a single clone of the NHU-ZAA strain and inoculate it in a 50-mL shake flask containing 10 mL of seed medium, at a rotation speed of 200 rpm, and incubate at 30°C for 23 hours.

[0128] Secondary seeds: transfer 1% of the first-grade seeds to a 50mL shake flask containing 20mL of seed medium, and cultivate them at 30°C and 200rpm for 23 hours to obtain the second-grade seeds.

[0129] Fermentation culture: inoculate 1% secondary seeds into 500mL containing 100mL fermentation medium, and culture at 30°C and 200rpm for 120h. Collect the bacterial fluid.

[0130] Among them, the seed medium contains per 100mL: (NH 4 ) 2 SO 4 0.25g, corn steep liquor 0.05g, yeast extract 0.14g, NaCl 0.2g, glucose 0.3g, K 2 HPO 4 0.05g, KH 2 PO 4 0.05g, MgSO 4 0.1g, FeSO 4 0.01g, CoCl 2 0.003g, MnSO 4 0.0001g, Vitamin B1 0.1μg, Vitamin K 0.1μg, Vitamin A 0.15...

experiment example

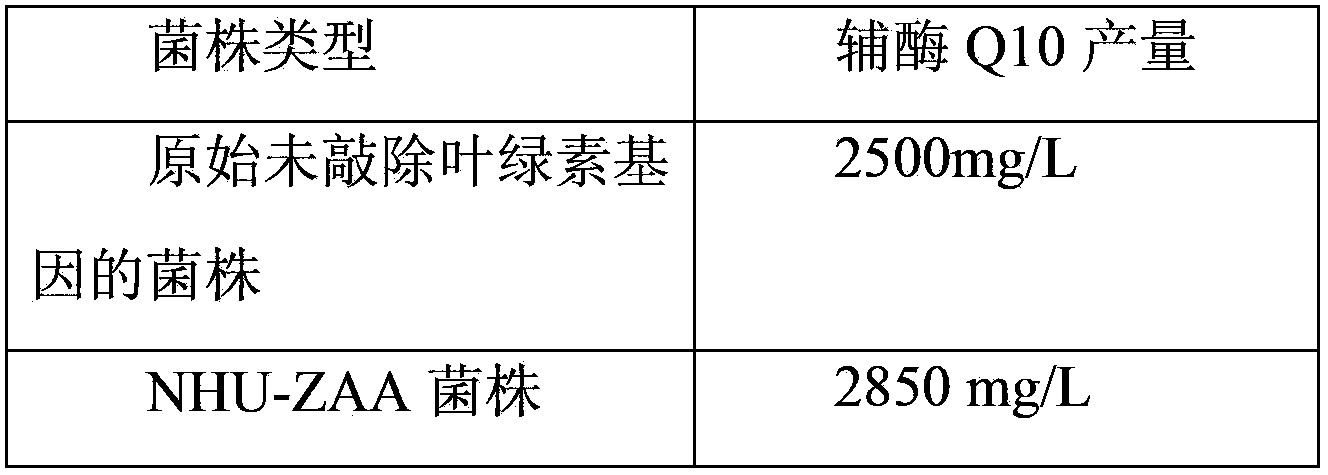

[0132] Experimental example HPLC is used to detect the comparison of the production of coenzyme Q10 produced by the strain without the chlorophyll gene and the NHU-ZAA strain, as shown in Table 1:

[0133] Table 1 Comparison of coenzyme Q10 production before and after strain transformation

[0134]

[0135] From the above table, the coenzyme Q10 output of the transformed strain increased from 2500mg / L to 2850mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com