Method for preparing coal flotation agent by using animal and plant grease and waste oil

A technology for animal and vegetable oils and flotation agents, which is applied in the refining of metal oxides, petroleum industry, cracking, etc., can solve the problems of inability to solve the problem of waste oil utilization, high purity and high cost, and difficulty in product marketing. It has the advantages of recyclability, simple and easy preparation method, and low cost of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

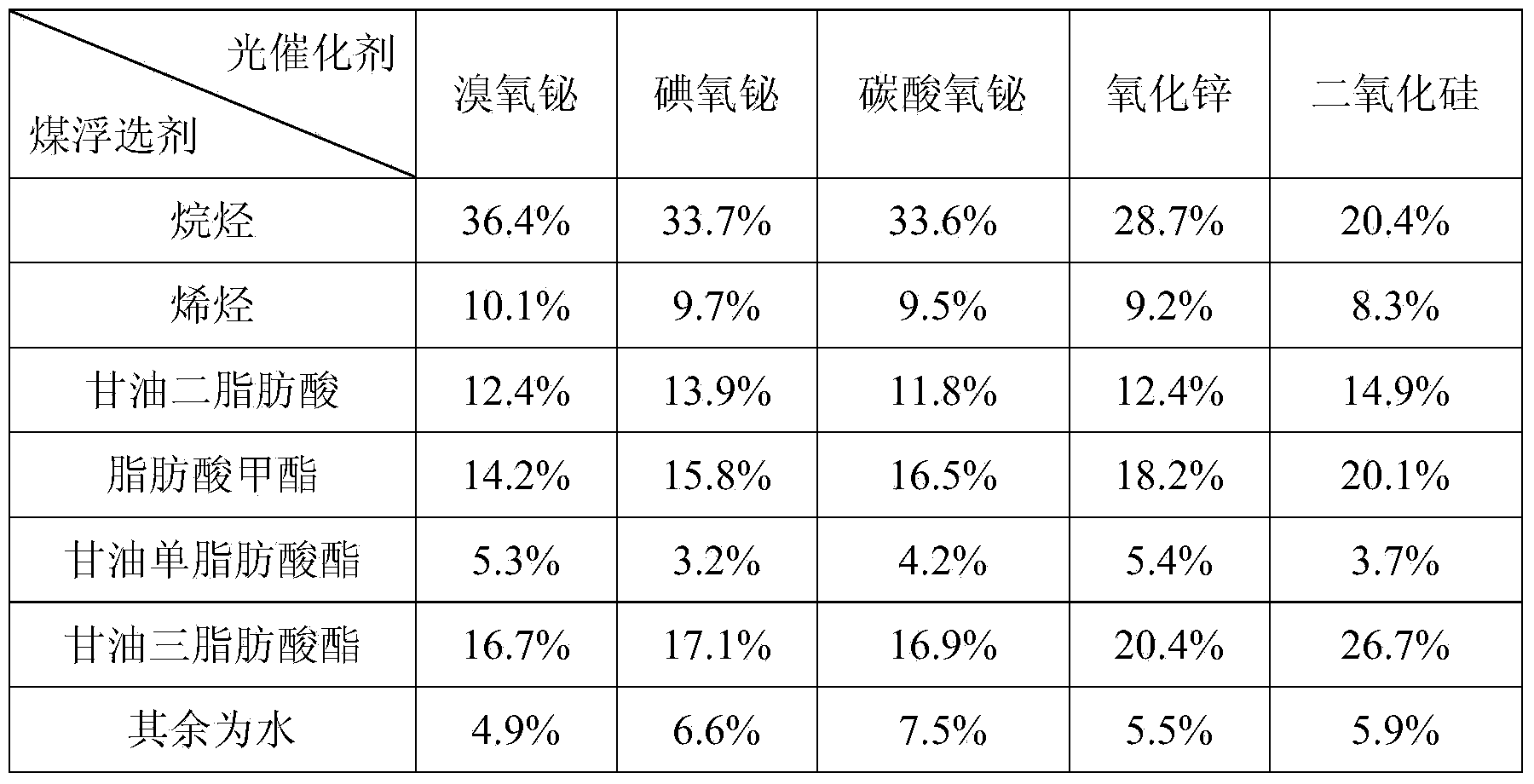

[0027] The filtered weight is 100g of waste oil. After analysis, the contents of free fatty acid and triglyceride fatty acid are 10.5% and 89.5%, respectively. , turn on the ultraviolet light for 4 hours, turn off the ultraviolet light and let the product stand for 1 hour, then take the upper layer and wash it with distilled water, then separate the water and the product with the help of a centrifuge, repeat 3 times, and get an oily liquid, that is, a coal float Choose agent. After analysis, it can be seen that in the coal flotation agent, there are 36.2% alkanes, 8.8% olefins, 13.3% diglyceride fatty acid content, 13.4% fat methyl ester content, 5.2% glycerol monofatty acid ester, 15.5% triglyceride fatty acid ester, and the rest for water.

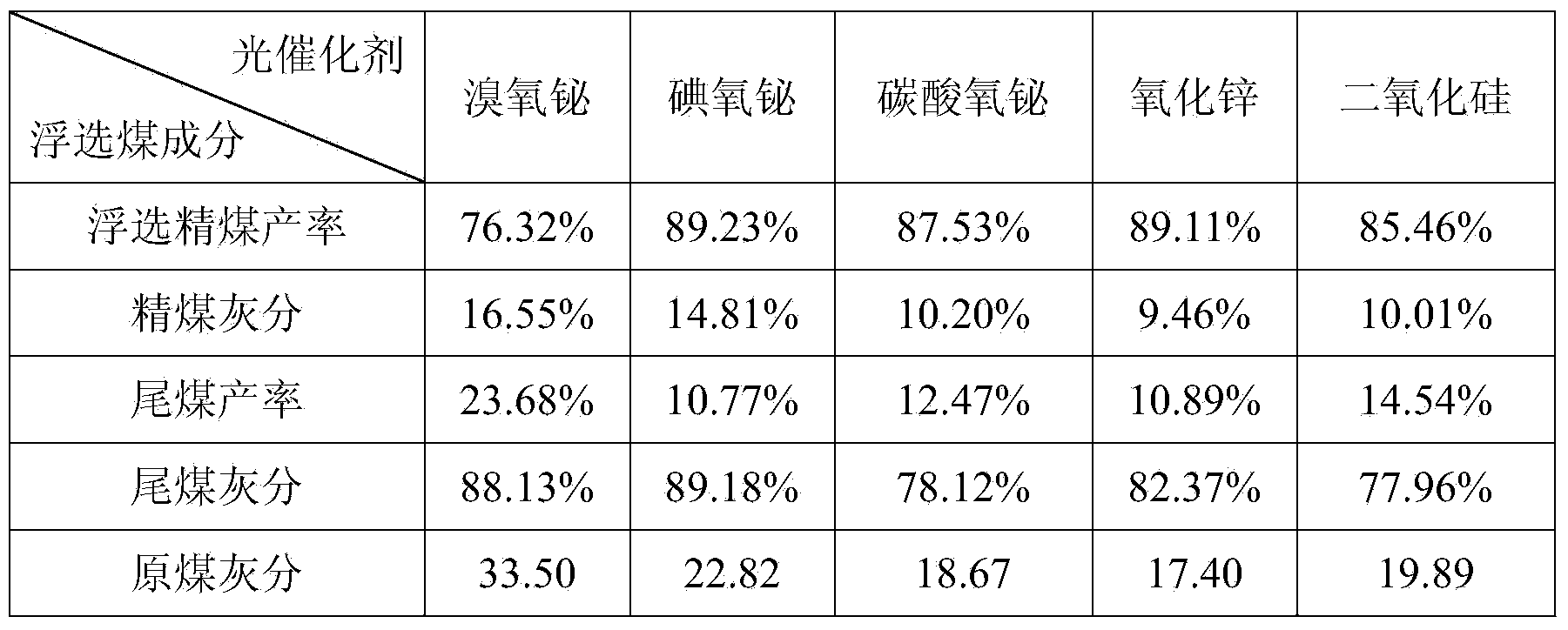

[0028] Take 151g of coal samples from Yima Mine in Henan Province (moisture content 0.73%, ash content 22.82%), use XFD-1.5 flotation machine for flotation, the concentration of coal slurry is 100g / L, add 1g of coal flotation agent to t...

Embodiment approach 2

[0030] The filtered weight is 100g of waste oil. After analysis, the contents of free fatty acid and triglyceride fatty acid are 10.5% and 89.5%, respectively. Stir for 1 hour, turn on the UV light for 3 hours, turn off the UV light and let the product stand for 1.5 hours, then take the supernatant and wash it with distilled water, then separate the water and the product with the help of a centrifuge, and repeat 3 times to obtain an oily liquid, namely To obtain coal flotation agent. The analysis shows that in the coal flotation agent, there are 38.2% alkanes, 9.2% olefins, 13.7% diglyceride fatty acid content, 16.4% fat methyl ester content, 3.5% glycerol monofatty acid ester, 14.9% triglyceride fatty acid ester, and the rest for water.

[0031] Take 151g of coal samples from Lu'an Mine in Shanxi (0.46% moisture, 30.36% ash), and use XFD-1.5 flotation machine for flotation, the concentration of coal slurry is 100g / L, and add 1g of coal flotation agent to the coal slurry In ...

Embodiment approach 3

[0033] Filtration weight is 100g waste oil, and the content of free fatty acid and triglyceride fatty acid is respectively 10.5% and 89.5% through analysis, and above-mentioned oil is poured in the beaker that fills 50g water, and getting photocatalyst titanium dioxide and silicon dioxide ratio is 1: 1 The weight is 1g, and it is stirred indoors in the dark for 1 hour. Turn on the simulated solar lamp for 4 hours, turn off the simulated solar lamp and let the product stand for 2 hours. Then, take the upper layer and wash it with distilled water, and then separate the water and the product with the help of a centrifuge , repeated 3 times to obtain an oily liquid, that is, a coal flotation agent. The analysis shows that the coal flotation agent contains 40.7% alkanes, 10.4% olefins, 11.3% diglyceride fatty acid content, 8.4% fat methyl ester content, 4.4% glycerol monofatty acid ester, 16.5% triglyceride fatty acid ester, and the rest for water.

[0034] Take 156g of coal sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com